Silicate microporous insulation plate and preparation method thereof

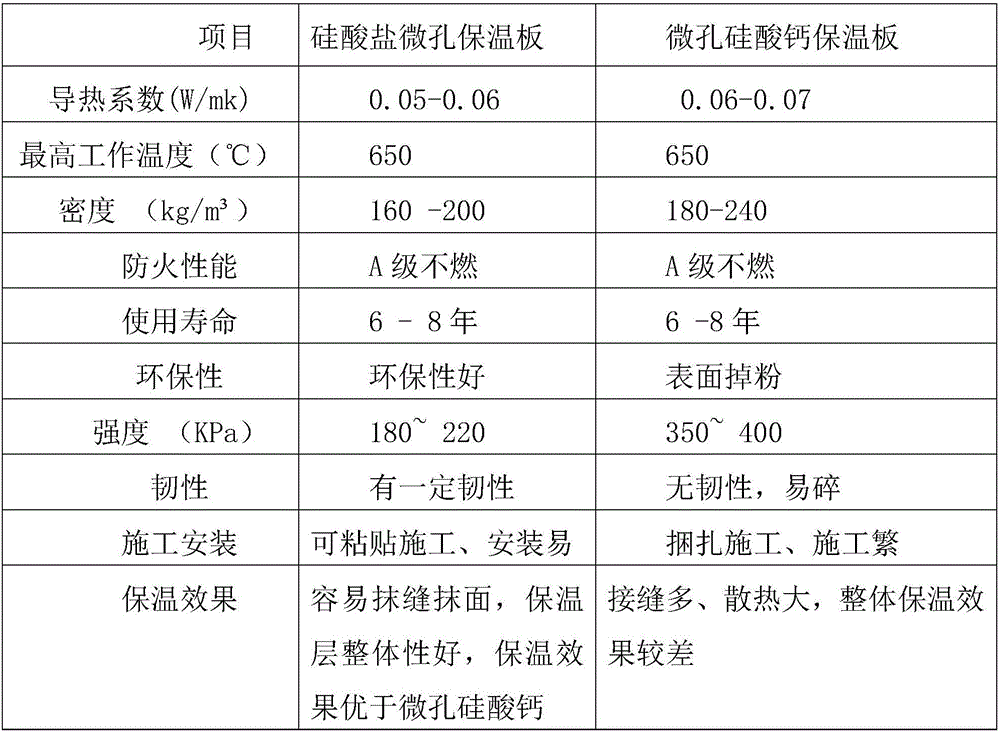

A silicate and thermal insulation board technology, applied in the field of silicate microporous thermal insulation board, silicate semi-hard microporous thermal insulation board or semi-hard microporous thermal insulation board, can solve the problem of decreased thermal insulation performance and easy powder drop. , can not be trampled and other issues, to achieve the effect of improved thermal insulation, improved environmental protection, and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

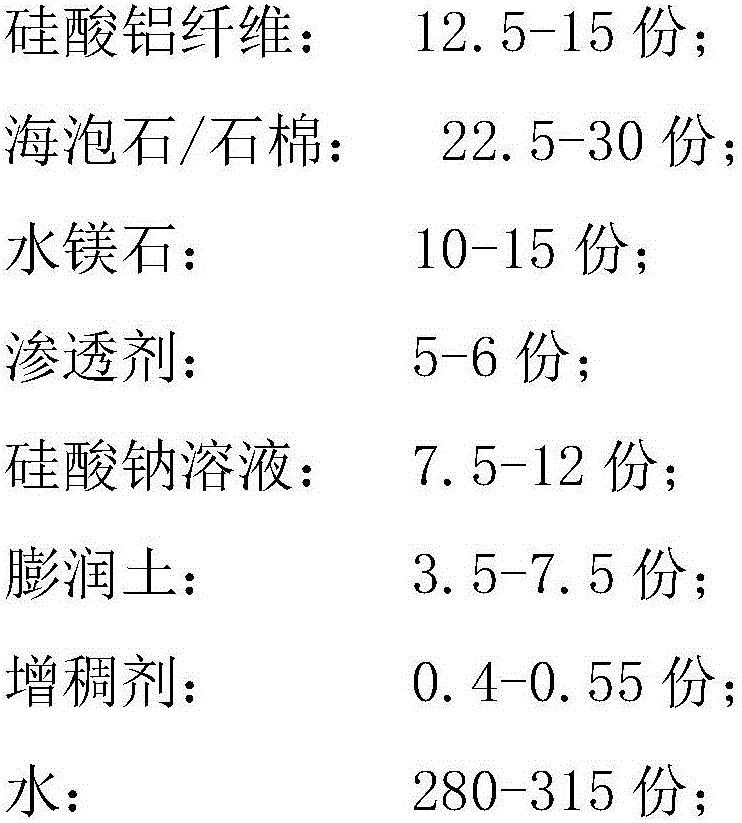

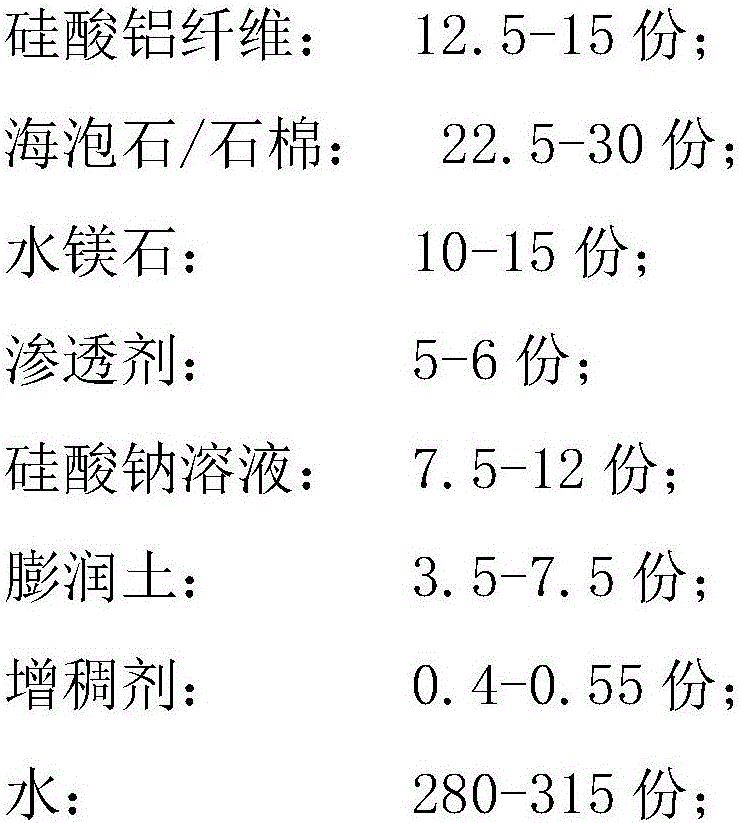

[0029] The present embodiment provides a silicate microporous insulation board, which consists of 100 parts of silicate insulation slurry and 13.5-15 parts (preferably 13.5 parts) with a density of 60-80 kg / m 3 (preferably 60kg / m 3 ), the expanded perlite with a particle size of 30–50 is used as a filler, and it is obtained by heating and drying after mixing evenly. The dried silicate microporous insulation board has a microporous structure invisible to the naked eye. The diameter is micron to nanometer, the density is 160-200kg / m 3 , the strength reaches about 200Kpa.

[0030] The preparation method of the silicate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com