High electrostrictive strain lead-free piezoelectric material under low electric field driving and preparing method

A lead-free piezoelectric and driver technology, used in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., to achieve the effects of excellent fatigue resistance, superior strain performance, and easy synthesis and sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

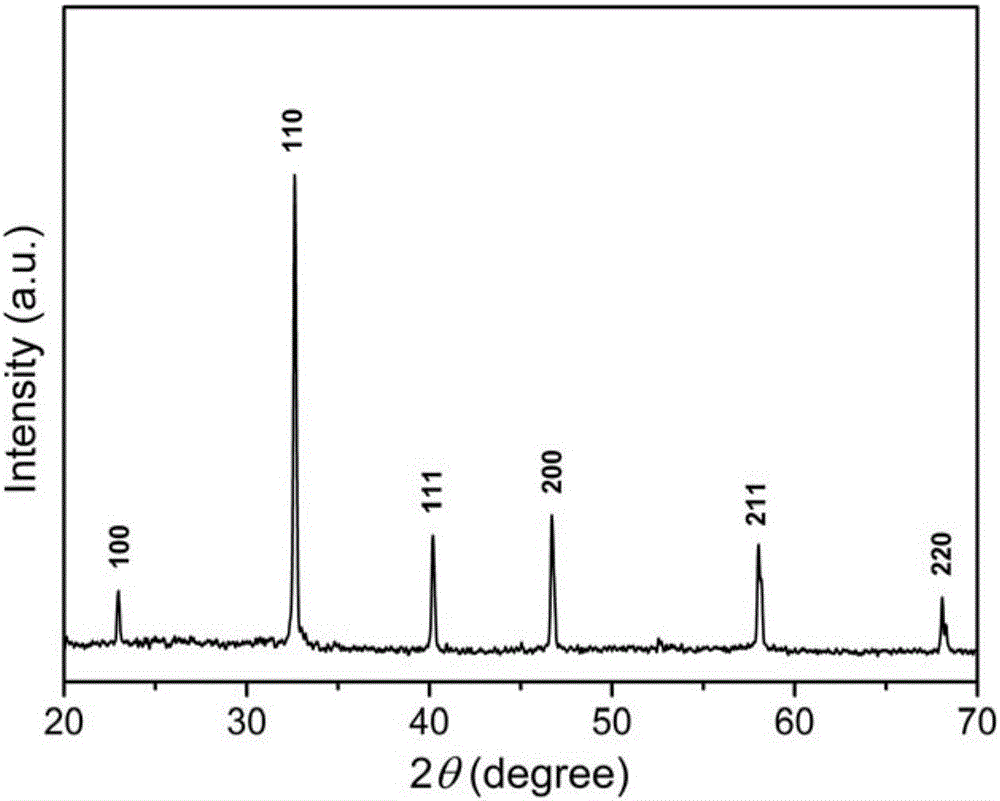

[0062] Preparation of (0.935-x) (Bi 0.5 Na 0.5 )TiO 3 -0.065BaTiO 3 -xA 2 BYZGR 6 Lead-free piezoelectric material, wherein, A=Pr, B=Ni, x=0.002, 0.004, 0.006, 0.007, 0.008, 0.009, 0.010, 0.012.

[0063] By Bi 2 o 3 、Na 2 CO 3 、TiO 2 、BaCO 3 、Pr 6 o 11 , NiO and MnO 2 (analytical pure) as raw material, according to (0.935-x) (Bi 0.5 Na 0.5 )TiO 3 -0.065BaTiO 3 -xPr 2 NiMnO 6 The stoichiometric ratio (molar ratio) of Bi, Na, Ti, Ba, Pr, Ni and Mn in (x=0.002, 0.004, 0.006, 0.007, 0.008, 0.009, 0.010, 0.012) Weigh the raw material, use dehydrated alcohol as medium and use ZrO 2 The balls were milled in a polytetrafluoroethylene ball mill jar for 24 hours, wherein the ball milling speed was 100-150 rpm, the mass ratio of the added zirconia balls to the ball milling material was 1.8:1, and the added anhydrous ethanol and ball milling material The mass ratio is 2.3:1. Then, dry, press into blocks and place in a closed Al 2 o 3 In the crucible, it was pre-fir...

Embodiment 2

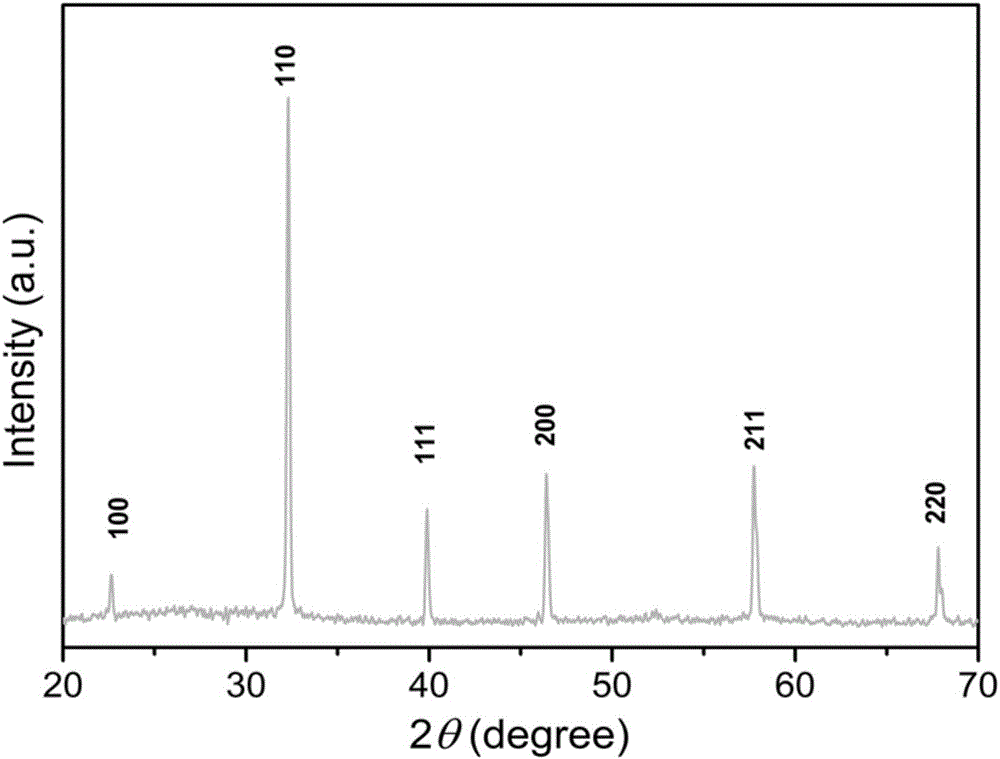

[0069] Preparation of (0.935-x) (Bi 0.5 Na 0.5 )TiO 3 -0.065BaTiO 3 -xA 2 BYZGR 6 Lead-free piezoelectric material, wherein, A=Sm, B=Ni, x=0.002, 0.004, 0.006, 0.007, 0.008, 0.009, 0.010, 0.012.

[0070] By Bi 2 o 3 、Na 2 CO 3 、TiO 2 、BaCO 3 、Sm 2 o 3 , NiO and MnO 2 (analytical pure) as raw material, according to (0.935-x) (Bi 0.5 Na 0.5 )TiO 3 -0.065BaTiO 3 -xSm 2 NiMnO 6 The stoichiometric ratio (molar ratio) of Bi, Na, Ti, Ba, Sm, Ni and Mn in (x=0.002, 0.004, 0.006, 0.007, 0.008, 0.009, 0.010, 0.012) Weigh raw materials, use dehydrated alcohol as medium and use ZrO 2 The balls were milled in a polytetrafluoroethylene ball mill jar for 15 hours, wherein the ball milling speed was 100-150 rpm, the mass ratio of the added zirconia balls to the ball milling material was 1.5:1, and the added anhydrous ethanol and ball milling material The mass ratio is 2.0:1. Then, dry, press into blocks and place in a closed Al 2 o 3 In the crucible, it was pre-fired a...

Embodiment 3

[0074] Preparation of (0.935-x) (Bi 0.5 Na 0.5 )TiO 3 -0.065BaTiO 3 -xA 2 BYZGR 6 Lead-free piezoelectric material, wherein, A=Eu, B=Ni, x=0.002, 0.004, 0.006, 0.007, 0.008, 0.009, 0.010, 0.012.

[0075] By Bi 2 o 3 、Na 2 CO 3 、TiO 2 、BaCO 3 、Eu 2 o 3 , NiO and MnO 2 (analytical pure) as raw material, according to (0.935-x) (Bi 0.5 Na 0.5 )TiO 3 -0.065BaTiO 3 -xEu 2 NiMnO 6 The stoichiometric ratio (molar ratio) of Bi, Na, Ti, Ba, Eu, Ni and Mn in (x=0.002, 0.004, 0.006, 0.007, 0.008, 0.009, 0.010, 0.012) Weigh raw materials, use dehydrated alcohol as medium and use ZrO 2 The balls were milled in a polytetrafluoroethylene ball mill jar for 24 hours, wherein the ball milling speed was 100-150 rpm, the mass ratio of the added zirconia balls to the ball milling material was 1.8:1, and the added anhydrous ethanol and ball milling material The mass ratio is 2.5:1. Then, dry, press into blocks and place in a closed Al 2 o 3 In the crucible, it was pre-fired a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com