Novel additive for improving tumbler strength of vanadium-titanium magnet sintered ore

A technology of drum strength and vanadium-titanium magnet, applied in the field of sintering in iron and steel enterprises, can solve the problems of low yield of vanadium-titanium sintered ore, high pulverization rate, small particle size of vanadium-titanium sintered ore, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

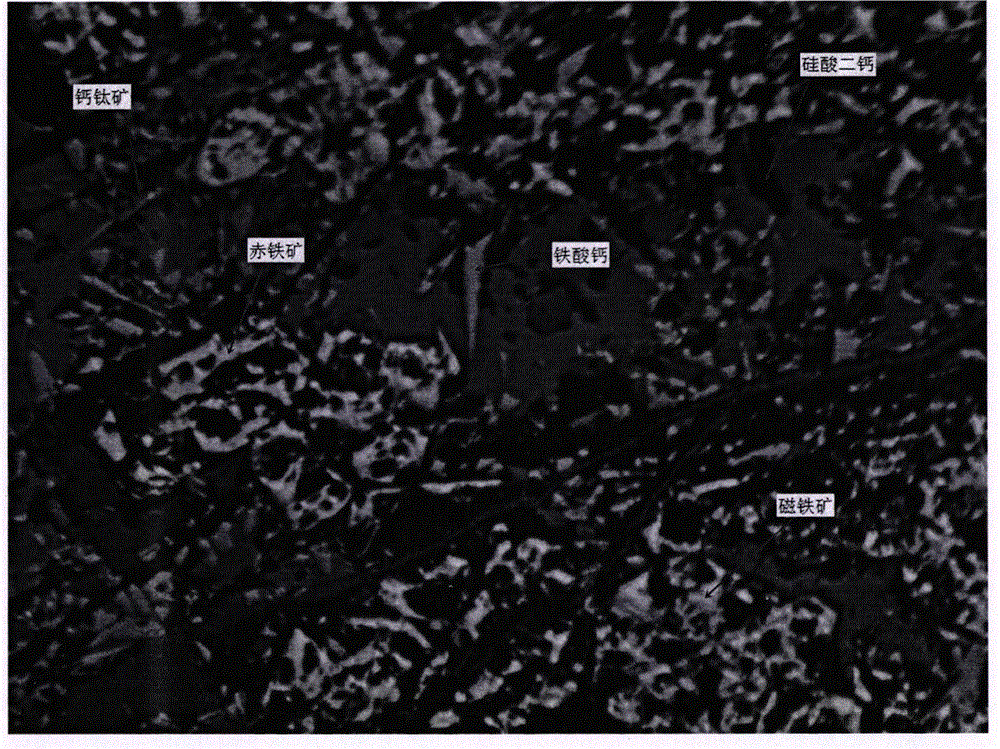

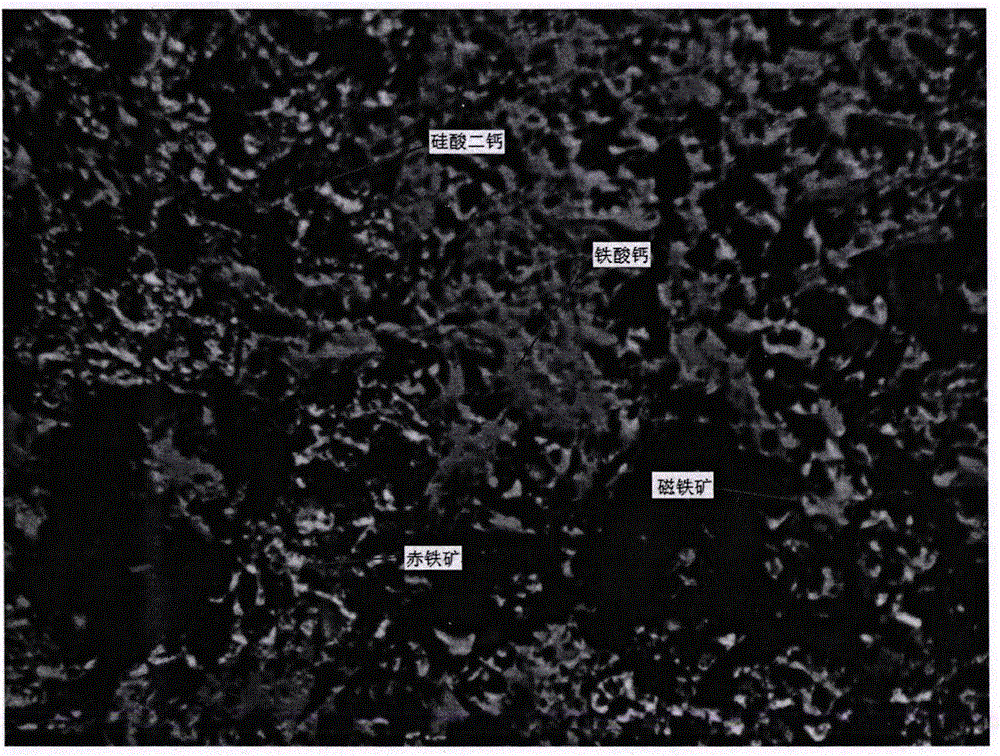

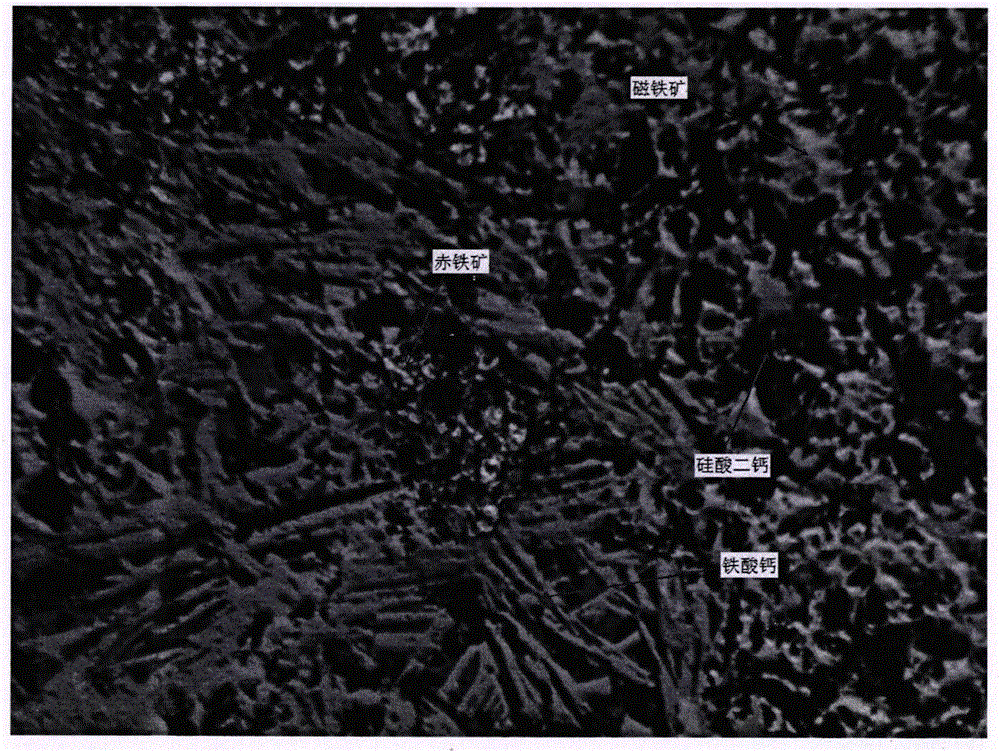

Image

Examples

specific Embodiment 1

[0026] Dissolve a certain amount of reagent in an appropriate amount of water to make a solution and add it to the mixed iron material for sintering cup test. After the test, a certain proportion of finished sintered ore is taken for drum strength testing. The sintering test parameters and drum strength test results are shown in Table 1.

[0027] Table 1 Test results of additive sintered cup %

[0028]

[0029] It can be seen from Table 1 that the finished product rate of vanadium-titanium magnetite sintered raw ore (sample 1) is 80.50%, and the drum strength is 58.57%. The yield rate of sample 2 (addition amount is 0.4‰) is 81.02%, and the drum strength is 59.38%. The drum strength of sample 2 is slightly higher than that of sintered ore. Sample 3 (with an addition of 0.5‰) had a yield of 80.79% and drum strength of 60.80%. The finished product rate of sample 4 (addition amount is 0.6‰) is 80.51%, and the drum strength is 62.03%. Compared with the raw sintered ore (sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com