Flocculation washing machine

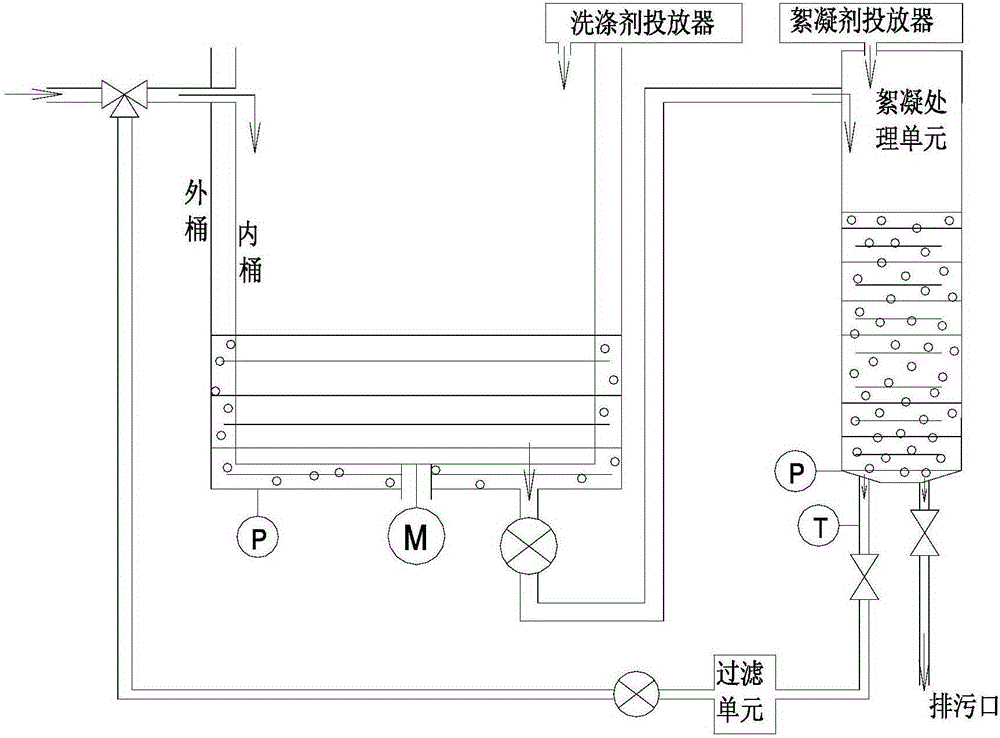

A flocculation washing machine and washing machine technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of large water consumption, water waste and other problems, and achieve the effects of simple structure, remarkable effect, and suitable promotion and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

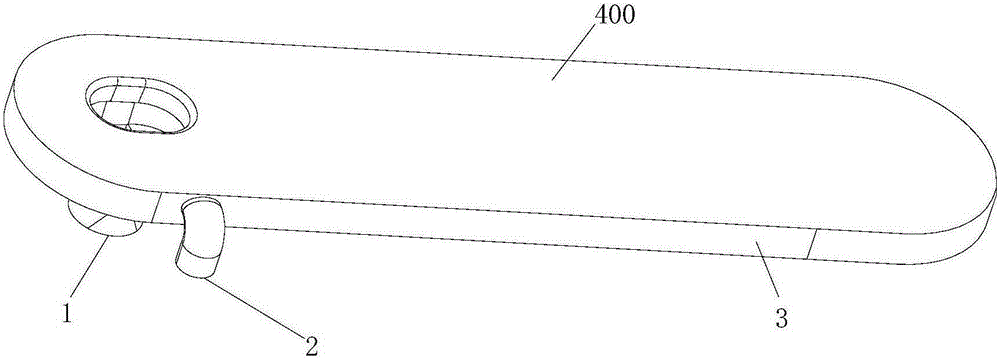

[0040] like Figures 2 to 7 As shown, in the embodiment of the present invention, the funnel 1 is provided with an inwardly protruding inner flange 4 , and the cavity between the inner flange 4 and the funnel 1 forms a uniform water channel 9 . Preferably, the inner turning edge 4 is a hemming structure protruding inward along the upper edge of the funnel 1 for a certain distance, and the extension end is bent downward. There is a certain distance between the lower end of the inner turning edge 4 and the funnel 1. The gap is to make the uniform water channel 9 formed by the cavity between the inner flange 4 and the funnel 1 communicate with the funnel 1, so that the washing water can be evenly flowed downward along the side wall of the funnel by the effect of the uniform water channel.

[0041] like Image 6 As shown, in the embodiment of the present invention, the bending portion of the inner flange 4 is set to gradually incline outward from top to bottom, so that the width ...

Embodiment 2

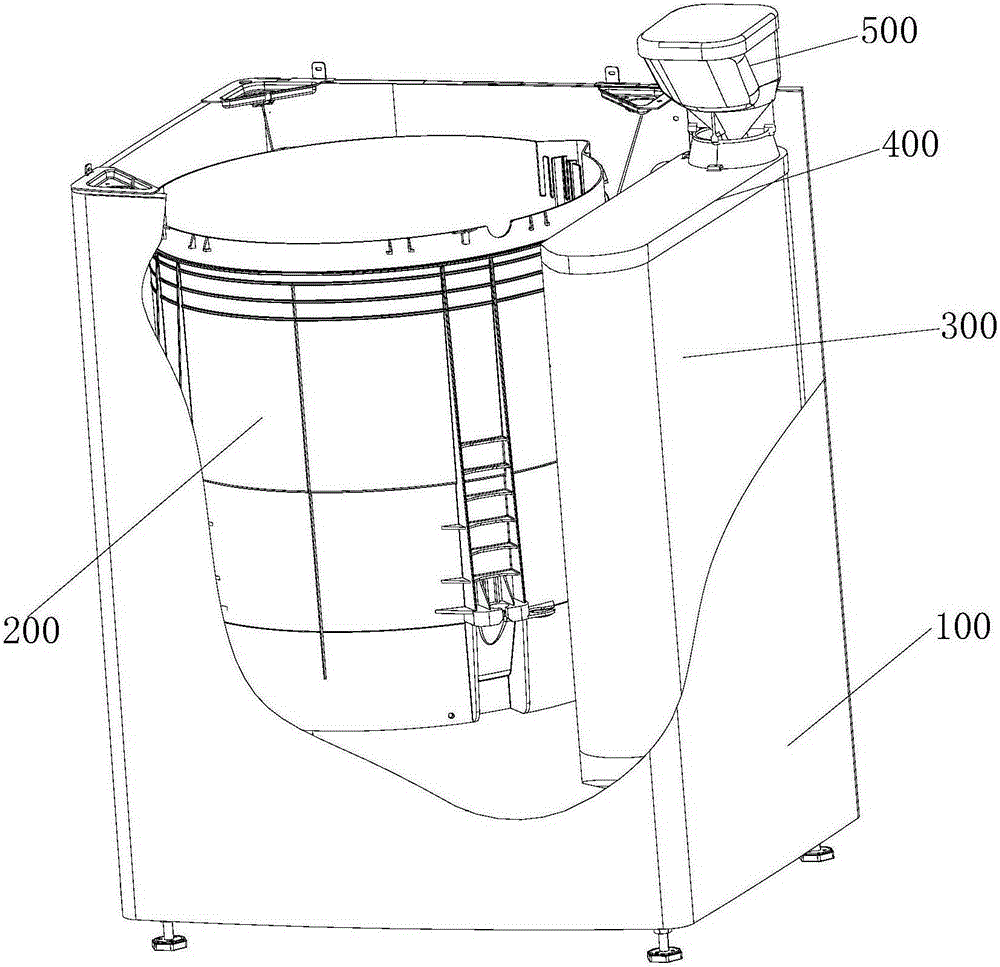

[0044] like Figure 2 to Figure 7 As shown, in this embodiment, the funnel 1 corresponding to the uniform water channel 9 is provided with at least one through hole, and each through hole communicates with the water inlet 2 of the flocculation bucket 300 through connecting pipes. The water inlet 2 of the flocculation bucket 300 is connected with the outer bucket 200 of the washing machine through the pipeline provided with the first water pump, so that the washing water in the outer bucket 200 can flow into the uniform water channel 9 through the water inlet 2 .

[0045] In this embodiment, the connecting pipe is integrally formed with the upper cover 400 ; preferably, the connecting pipe is an integrally formed cavity pipeline protruding from the lower side of the upper cover 400 .

[0046] In this embodiment, the connecting pipe extends horizontally outward from the funnel 1 to protrude from the outer periphery of the upper cover 400, and the protruding end of the connecting...

Embodiment 3

[0050] like Figure 2 to Figure 7 As shown, in this embodiment, the upper cover 400 is also provided with an annular cavity 5, the annular cavity 5 is set close to the inner wall of the flocculation bucket 300, and the bottom of the annular cavity 5 is evenly arranged A spray hole 8 for spraying water to the inner wall of the flocculation bucket 300.

[0051] In this embodiment, the annular cavity 5 is an integrally formed cavity structure in which the upper cover 400 protrudes downward, so that the protruding annular cavity 5 can be used as a reinforcing rib of the upper cover 400 to improve The compressive strength of the upper cover 400.

[0052] By setting an annular cavity on the upper cover and evenly arranging the spray holes on the annular cavity, the incoming water can be evenly sprayed to the inner wall of the flocculation barrel through the spray holes, so as to clean the inner wall of the flocculation barrel and reduce flocculation The purpose of impurities attac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com