Method for preparing of insulating paper containing modified montmorillonite

A technology of montmorillonite and insulating paper, which is applied in the field of transposition wire core packaging materials, can solve the problems of unstable performance and uneven distribution of insulating paper, so as to reduce the relative permittivity, suppress partial discharge, and improve the impact. The effect of wear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

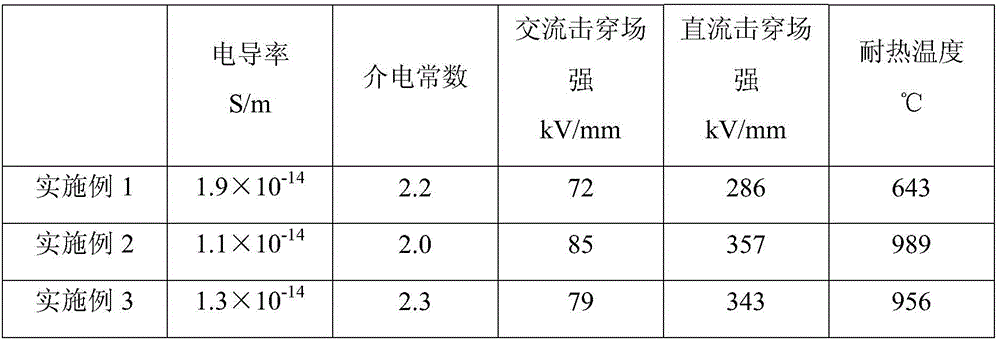

Examples

Embodiment 1

[0021] A preparation method for insulating paper containing modified montmorillonite, comprising the following steps:

[0022] Step 1, preparation of concentrated pulp: the cardboard is cracked by a pulper and then sent to a refiner for refining. The air source of the refiner is 0.5MPa, and the linear speed difference between the chassis and the knife roller is 5.9m / s, the voltage is 400V, the three-phase is 55Hz, and the beating pressure is 1.8kg / cm; the deflaking machine is used for deflaking treatment, and then the concentration of the pulp after the deflaking treatment is concentrated to 4.8%;

[0023] Step 2, preparation of modified montmorillonite: in parts by weight, mix 19 parts of montmorillonite, 11 parts of nano-zinc oxide, 7 parts of sodium chloride, 6 parts of sodium hydroxide, 1 part of magnesium sulfate, and 22 parts of water , the suspension was mechanically stirred and dispersed at a speed of 5000r / min, stirred for 10 minutes, and then ultrasonically disperse...

Embodiment 2

[0028] A preparation method for insulating paper containing modified montmorillonite, comprising the following steps:

[0029] Step 1, preparation of concentrated pulp: the cardboard is cracked by a pulper and then sent to a refiner for refining. The air source of the refiner is 0.8MPa, and the linear speed difference between the chassis and the knife roller is 6.9m / s. The voltage is 480V, the three-phase is 60Hz, and the beating pressure is 3.8kg / cm; the deflaking machine is used for deflaking treatment, and then the concentration of the pulp after the deflaking treatment is concentrated to 5.2%;

[0030] Step 2, preparation of modified montmorillonite: in parts by weight, mix 36 parts of montmorillonite, 13 parts of nano-zinc oxide, 12 parts of sodium chloride, 9 parts of sodium hydroxide, 5 parts of magnesium sulfate, and 31 parts of water , the suspension was mechanically stirred and dispersed at a speed of 6000r / min, stirred for 13 minutes, and ultrasonically dispersed f...

Embodiment 3

[0035] A preparation method for insulating paper containing modified montmorillonite, comprising the following steps:

[0036] Step 1, preparation of concentrated pulp: the cardboard is cracked by a pulper and then sent to a refiner for refining. The air source of the refiner is 1.2MPa, and the linear speed difference between the chassis and the knife roller is 7.5m / s. The voltage is 520V, the three-phase is 65Hz, and the beating pressure is 4.2kg / cm; the deflaking machine is used for deflaking treatment, and then the concentration of the pulp after the deflaking treatment is concentrated to 5.6%;

[0037] Step 2, preparation of modified montmorillonite: in parts by weight, mix 42 parts of montmorillonite, 17 parts of nano-zinc oxide, 16 parts of sodium chloride, 12 parts of sodium hydroxide, 7 parts of magnesium sulfate, and 38 parts of water , the suspension was mechanically stirred and dispersed at a speed of 6400r / min, stirred for 16 minutes, and then ultrasonically dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com