A kind of high-voltage rigid umbrella shed composite insulating cross-arm and its preparation device and method

A composite insulation and preparation device technology, which is applied in the field of high-voltage composite insulation cross-arm, can solve the problems of unspecified curing agent type, intensifying umbrella shed resin formula, unscientific and other problems, and achieve high bending strength, high toughness, and guaranteed durability. Effect of Aging Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is further described below in conjunction with accompanying drawing.

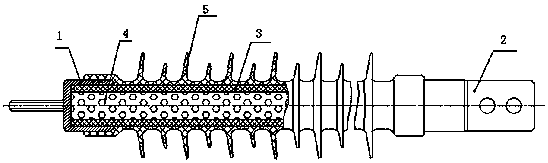

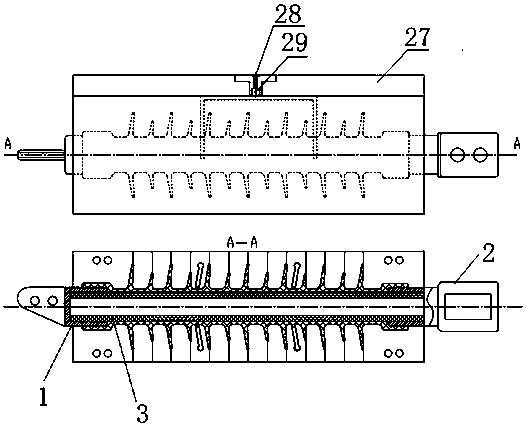

[0047] Such as figure 1 As shown, a high-strength composite insulating crossarm for high voltage, including metal connector A1, metal connector B2, the middle of metal connector A1, metal connector B2 is connected by insulating tube 3, and the inside of insulating tube 3 is filled with polyurethane foam The material 4 is covered with a hard cycloaliphatic epoxy resin shed 5, and the insulating tube 3 is made of continuous fiber pultrusion, fiber winding and fiber braiding into three layers of longitudinal fibers and impregnated with polyurethane resin. become.

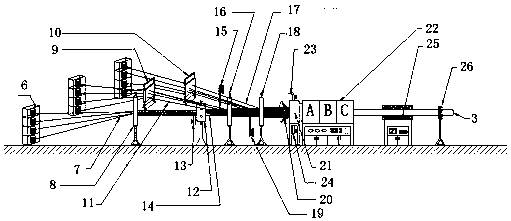

[0048] Such as figure 2 , 3 As shown, a high-voltage high-strength composite insulating cross-arm preparation device includes an insulating tube 3, and a creel 6 is connected to the thread carrier A8, the thread carrier B9, and the thread carrier C10 through the longitudinal inner fiber 7, and the thread carrier A8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com