Hydraulically-driven wave energy power generation device

A power generation device, wave energy technology, applied in the direction of fluid pressure actuation device, ocean energy power generation, engine components, etc., to achieve the effect of stable output pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

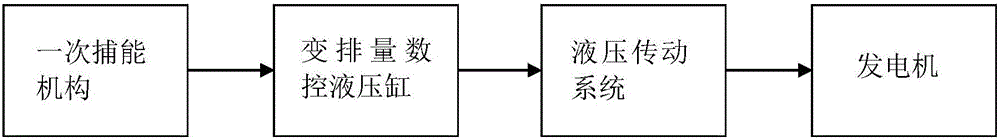

[0032] refer to figure 1 : A hydraulically driven wave energy generating device, including a primary energy harvesting mechanism, a variable displacement numerical control hydraulic cylinder connected behind the primary energy harvesting mechanism, a hydraulic transmission system driven by a variable displacement numerical control hydraulic cylinder, and a hydraulic transmission system connected behind the hydraulic transmission system dynamo.

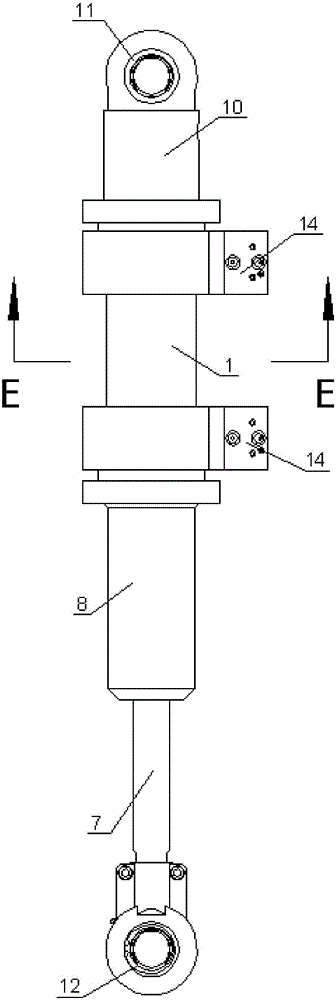

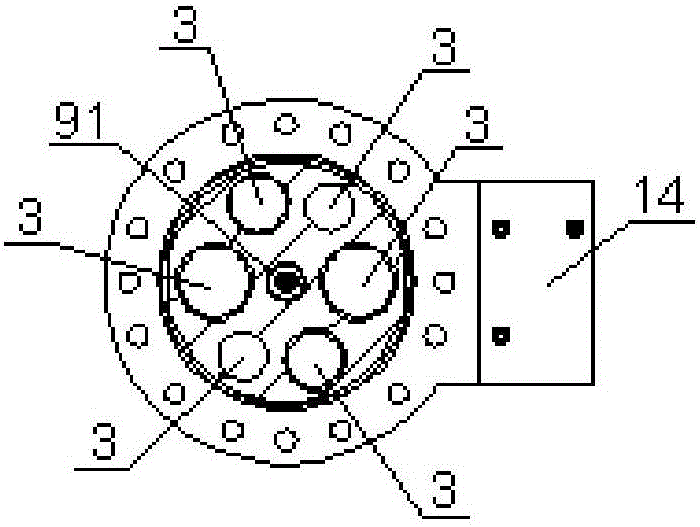

[0033] refer to Figure 2-Figure 5 : the variable-displacement numerical control hydraulic cylinder includes a cylindrical cylinder body 1, a cylinder head 2 fixed on the upper end of the cylinder body 1 by bolts, and the cylinder body 1 is punched multiple times through the same stamping process to form six windings. The centerline of the cylinder body 1 is a sub-hydraulic cylinder 3 arranged in a circle and a central hole 4 opened at the centerline of the cylinder body 1, and the central axes of the adjacent sub-hydraulic cylinders ...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 is that there are four groups of sub-hydraulic cylinders of the variable-displacement numerical control hydraulic cylinder, and each group has two sub-hydraulic cylinders, and the central axes of adjacent sub-hydraulic cylinders are equally spaced along the circumferential direction Set at 45 degrees, the area ratio of the four sub-hydraulic cylinders is S1:S2:S3:S4=1:2:4:8.

[0053] There are four groups of three-way switching valves corresponding to the four groups of sub-hydraulic cylinders, that is, eight. The outer wall of the cylinder of the variable-displacement numerical control hydraulic cylinder is also fixedly installed with two switching valve installation blocks, which are connected with the four sub-hydraulic cylinders. The four two-position three-way high-speed switch valves connected to the rod cavity of the hydraulic cylinder are installed on one switch valve installation block, and the four two-pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com