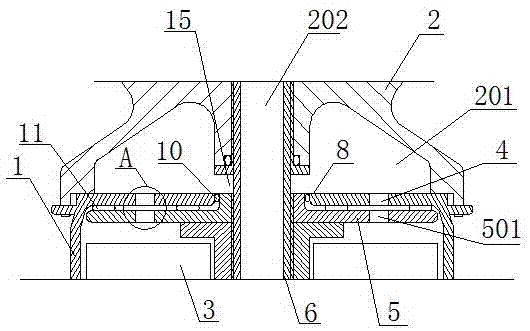

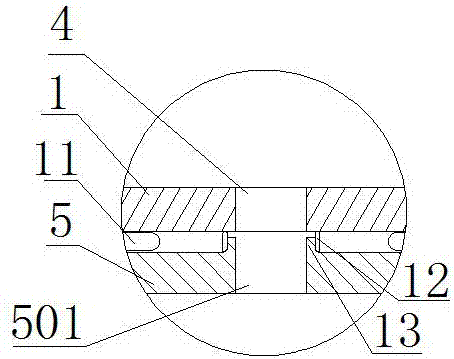

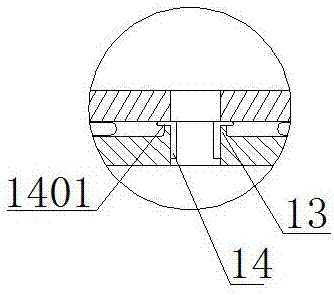

A sealing structure of a retaining plate for an oil filter

A technology of sealing structure and oil filter, which is applied in the direction of engine sealing, filter separation, machine/engine, etc., can solve the problem of insufficient sealing performance of the retaining plate, achieve enhanced work stability, eliminate thread looseness, and ensure tightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of elastic polyurethane material, its preparation technology comprises the following steps:

[0046] Step 1. To manufacture the improved TPU resin, place 26% simethicone oil, 38.5% TPR and 6% linseed oil in a turbo stirrer to mix evenly, and heat the mixture to 100°C , heat the silicone resin with a mass ratio of 7% to 160°C until it melts, then add it to the mixed solution, keep the temperature of the mixed solution at 100°C, and stir for 3 hours at a stirring speed of 600rad / min to obtain a mixed solution;

[0047] Step 2, the mass ratio is 10.8% talcum powder, 3.2% zinc stearate, 1.5% triethylamine neutralizing agent, 0.5% organic tin catalyst and 4.3% erucamide stirring and mixing in a blender After uniformity, add to the mixed solution in step 1 and stir to mix evenly, then send the mixed solution to the internal mixer for banburying for 8 hours, and finally add boric acid with a mass ratio of 2.2% to let it solidify and form, and then pass through a double-...

Embodiment 2

[0052] A kind of elastic polyurethane material, its preparation technology comprises the following steps:

[0053] Step 1. To manufacture the improved TPU resin, place 26% simethicone oil, 38.5% TPR and 6% linseed oil in a turbo stirrer to mix evenly, and heat the mixture to 100°C , heat the silicone resin with a mass ratio of 7% to 160°C until it melts, then add it to the mixed solution, keep the temperature of the mixed solution at 100°C, and stir for 3 hours at a stirring speed of 600rad / min to obtain a mixed solution;

[0054] Step 2, the mass ratio is 10.8% talcum powder, 3.2% zinc stearate, 1.5% triethylamine neutralizing agent, 0.5% organic tin catalyst and 4.3% erucamide stirring and mixing in a blender After uniformity, add to the mixed solution in step 1 and stir to mix evenly, then send the mixed solution to the internal mixer for banburying for 8 hours, and finally add boric acid with a mass ratio of 2.2% to let it solidify and form, and then pass through a double-...

Embodiment 3

[0059] A kind of elastic polyurethane material, its preparation technology comprises the following steps:

[0060] Step 1. To manufacture the improved TPU resin, place 26% simethicone oil, 38.5% TPR and 6% linseed oil in a turbo stirrer to mix evenly, and heat the mixture to 100°C , heat the silicone resin with a mass ratio of 7% to 160°C until it melts, then add it to the mixed solution, keep the temperature of the mixed solution at 100°C, and stir for 3 hours at a stirring speed of 600rad / min to obtain a mixed solution;

[0061] Step 2, the mass ratio is 10.8% talcum powder, 3.2% zinc stearate, 1.5% triethylamine neutralizing agent, 0.5% organic tin catalyst and 4.3% erucamide stirring and mixing in a blender After uniformity, add to the mixed solution in step 1, stir and mix evenly, then send the mixed solution to the internal mixer for internal mixing for 8 hours, and finally add boric acid with a mass ratio of 2.2% to solidify it, and then pass through a double-screw extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com