A solar lignite drying system with intelligent adjustment of fan power according to air inlet temperature

A drying system and solar energy technology, which is applied in the intersecting field of solar energy and drying, can solve the problems of low drying efficiency, large equipment, and high cost, and achieve the effects of intelligent drying control, improving drying efficiency, and reducing human intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

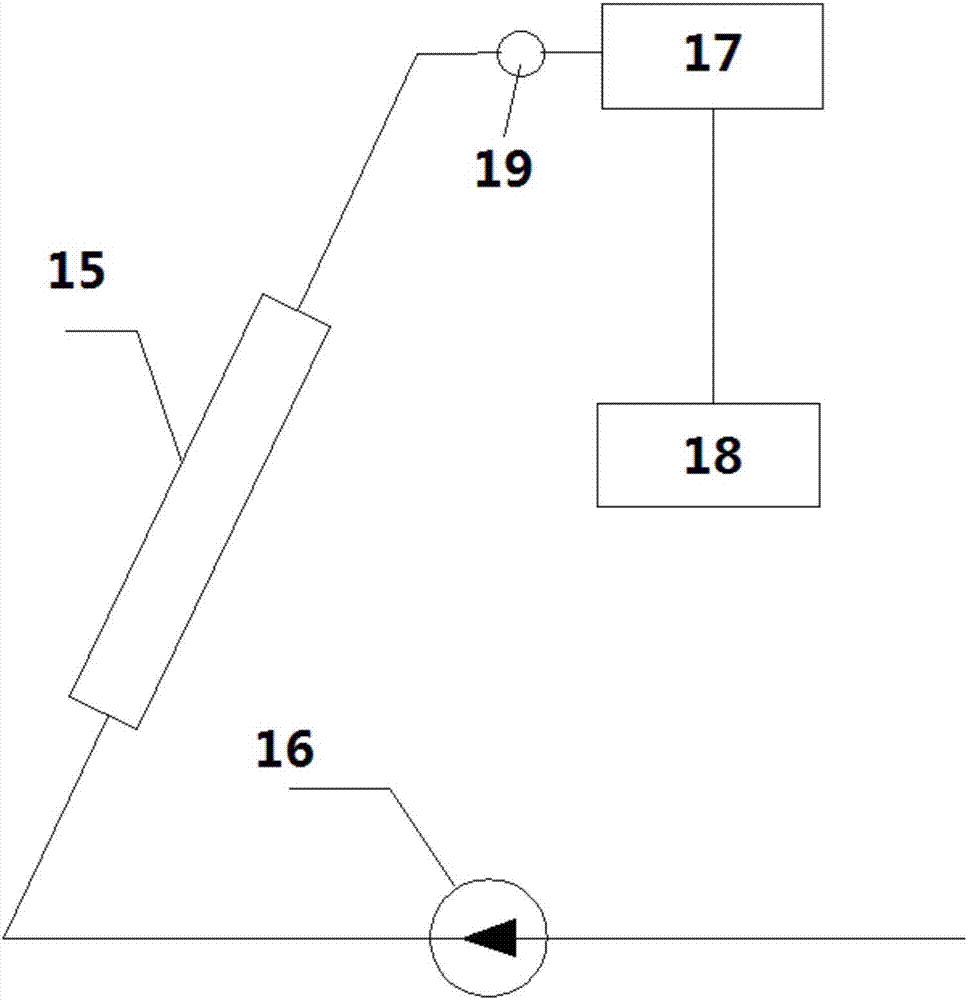

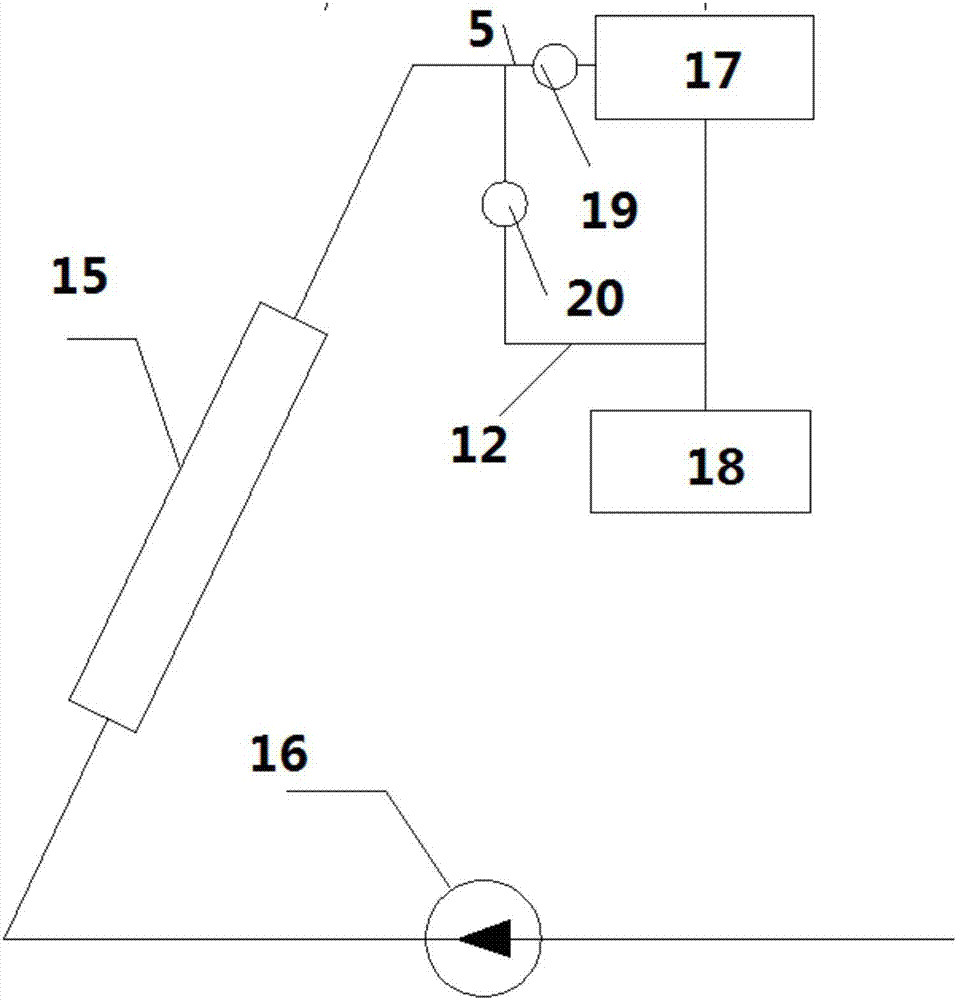

[0041] figure 1 Shown is a kind of solar lignite drying system, comprising solar thermal collector 15 and drying device 17, air enters solar thermal collector 15 through induced draft fan 16, and absorbs the heat of solar energy in solar thermal collector 15, forms hot air, so The hot air enters the drying device under the guidance of the fan 19 to dry the lignite.

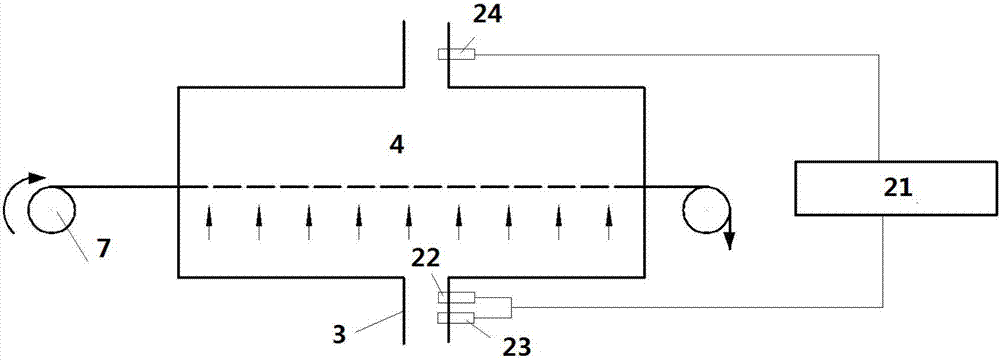

[0042] like image 3 As shown, the hot air enters the drying device 17 through the air inlet pipe 3, and a temperature sensor 22 and a flow sensor 23 are arranged on the air inlet pipe 3, and the temperature sensor 22 is used to measure the temperature of the hot air entering the drying device 17, The flow sensor 23 is used to detect the hot air flow of the drying device 17; the temperature sensor 22 and the flow sensor 23 are connected to the central controller 21 for data;

[0043] The central controller 21 automatically controls the power of the fan 19 according to the measured temperature of the hot air enteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com