Pipeline inner bore quality detection mini-sized mobile robot and control method therefor

A mobile robot, measurement control technology, applied in the direction of electromagnetic measuring device, electric/magnetic diameter measurement, etc., can solve the problems of low centering accuracy, low detection efficiency, large size, etc., achieve good reconfigurability, improve accuracy, The effect of low coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings.

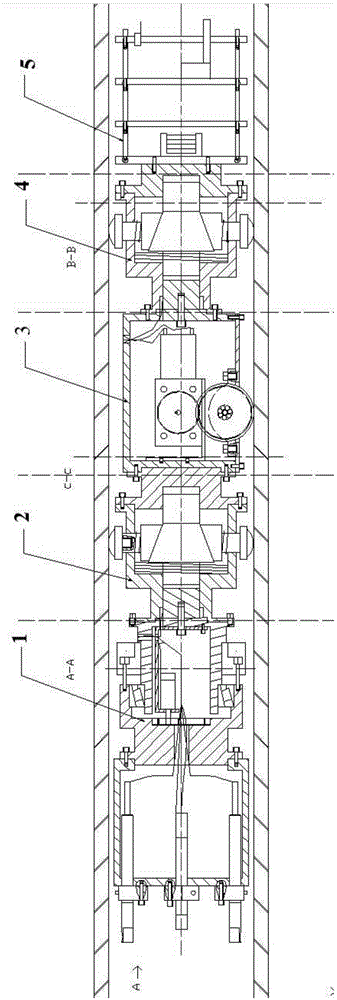

[0054] Such as figure 1 As shown, the micro mobile robot used for quality inspection of pipeline inner holes provided by the present invention includes a rotating scanning module 1 , a front centering and guiding module 2 , a driving walking module 3 , a rear centering and guiding module 4 and a measurement control module 5 . The rotating scanning module 1, the front centering and guiding module 2, the driving walking module 3, the rear centering and guiding module 4, and the measurement control module 5 are coaxially installed and connected in sequence from front to back, and the above five modules have the same common axis O.

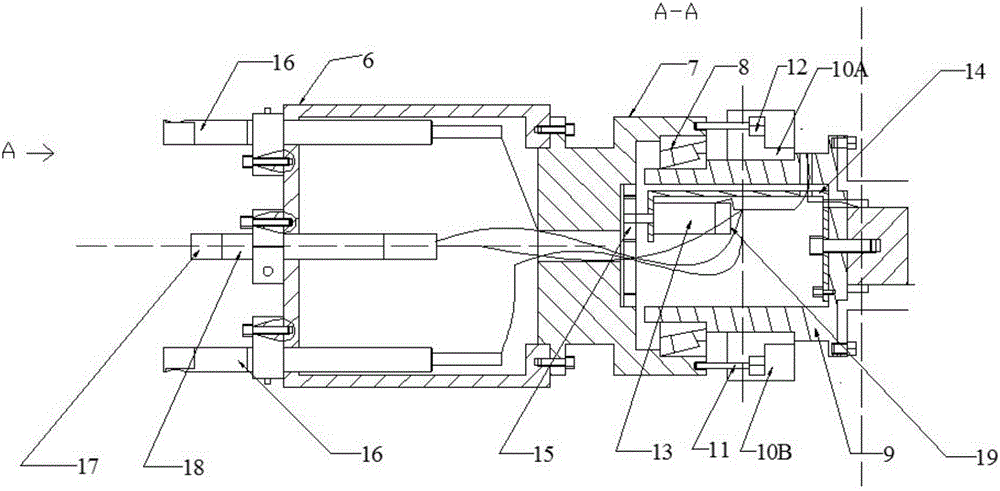

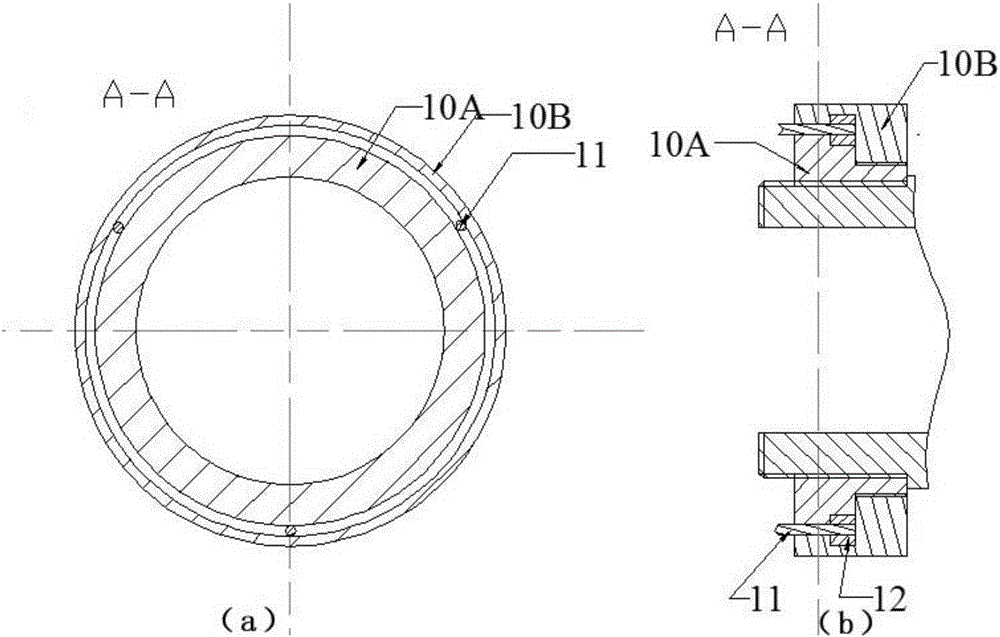

[0055] Such as figure 2 As shown, the rotating scanning module 1 includes a rotating sleeve 6, a rotating base 7, a first rolling bearing 8, a fixed base 9, a rotating cage 10, holding bolts 11, holding nuts 12, scanning motors 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com