Steel-ball diameter detecting system

A detection system and steel ball technology, which is applied to measurement devices, instruments, optical devices, etc., can solve the problems of inaccurate measurement and high requirements for operating proficiency, and achieve high detection efficiency, low technical ability requirements, and accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following, the present invention will be further described in detail with reference to the drawings of a steel ball sorting system using the system of the present invention.

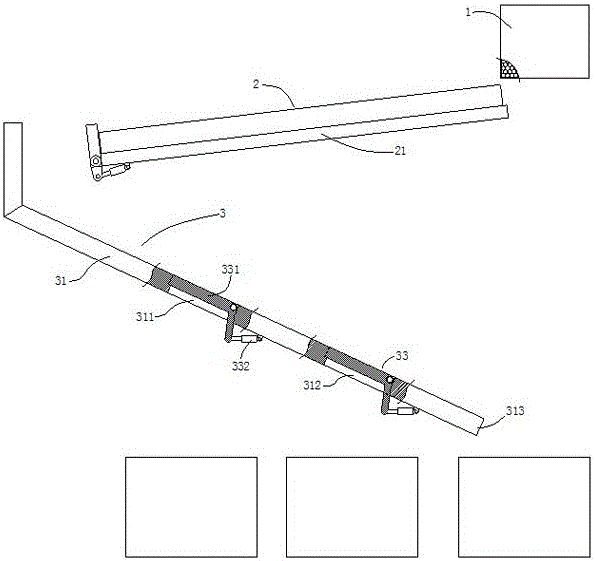

[0020] When implementing: Figure 1 ~ Figure 3 As shown, a steel ball sorting system based on a machine vision system includes a feeding device 1, a detection device 2, and a sorting device 3;

[0021] The feeding device 1 includes a storage box for storing steel balls to be sorted, the upper end of the storage box is open, and the lower end has a closable discharge port;

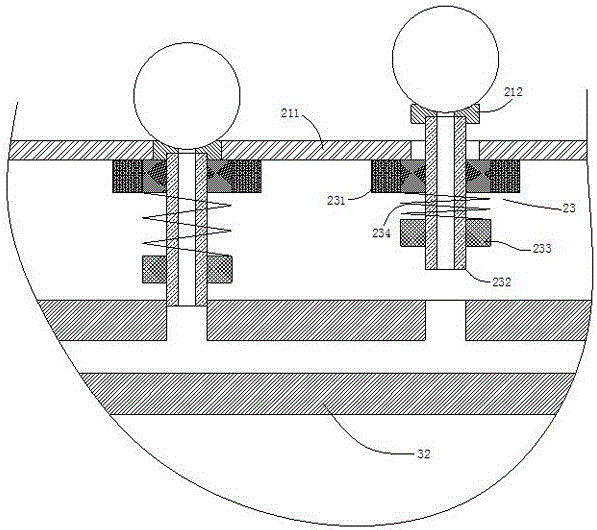

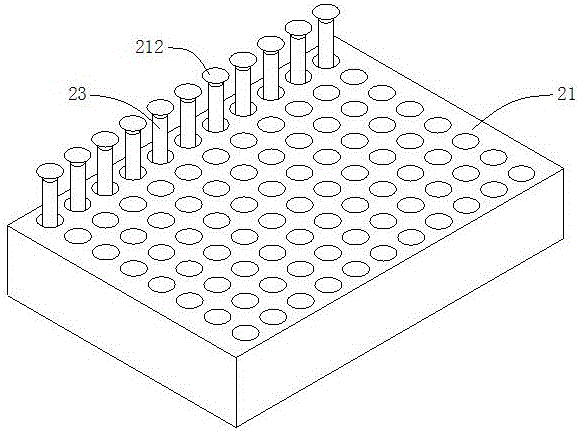

[0022] The detection device 2 includes a test bench 21 for fixing the steel balls to be tested, and the test bench 21 is located below the discharge port of the storage box; it also includes a machine vision system for detecting the diameter of the steel balls. The machine vision system includes an industrial camera for imaging the steel ball to be tested on the test bench 21, an image acquisition card 222 for collecting and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com