Monocular video high precision measuring method for wing wind tunnel test model elastic deformation

A technology of elastic deformation and wind tunnel test, applied in the field of wind tunnel test, it can solve the problems of bending deformation, reduction of Y coordinate value, coordinate value error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] A monocular video high-precision measurement method for elastic deformation of a wing wind tunnel test model, comprising the following steps:

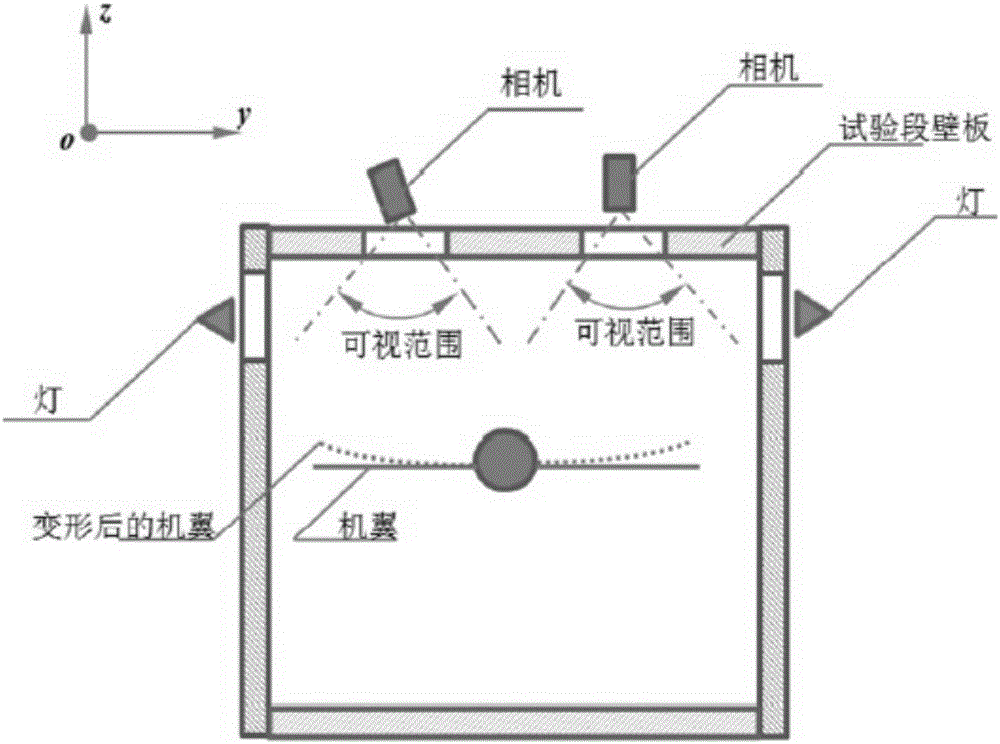

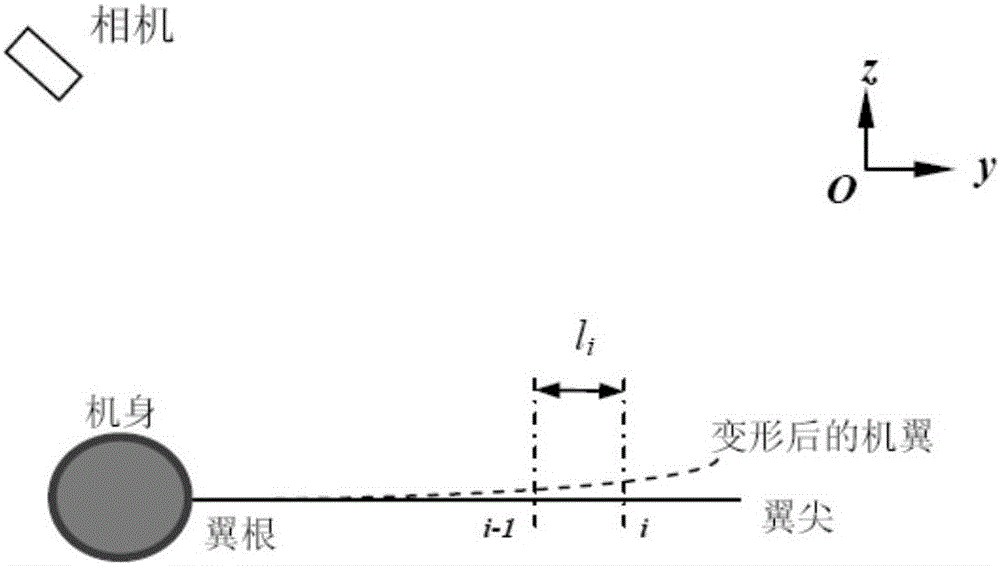

[0047] Step one, as figure 2 As shown, a camera is fixedly installed outside the wind tunnel observation window, and the camera pose parameters and focal length are adjusted to cover the measurement area of the entire wing test model;

[0048] Step 2. Use mature machine vision and photogrammetry methods to obtain the distortion parameters of the camera optical system and its figure 2 The pose parameters in the wind tunnel coordinate system yoz shown;

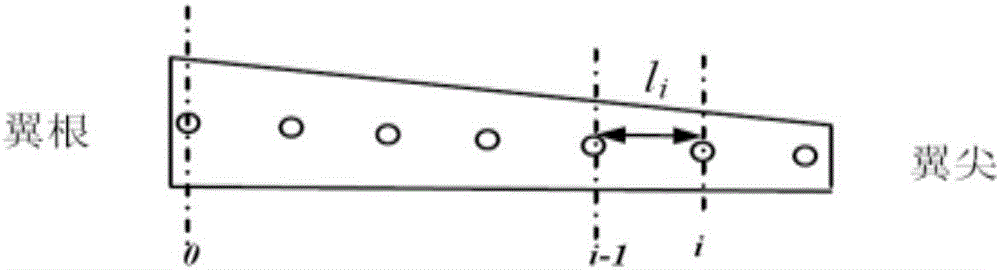

[0049] Step three, as image 3 Mark points are drawn on the upper surface of the neutral axis of the wing test model, each marking point determines a section, and the upper surface marking point of the neutral axis of the 0th section is set at the connection between the wing and the fuselage. At the root of the wing, there is no deformation here, i.e. draw a marker The de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com