Visualized explosive cooking-off and gas product analysis device

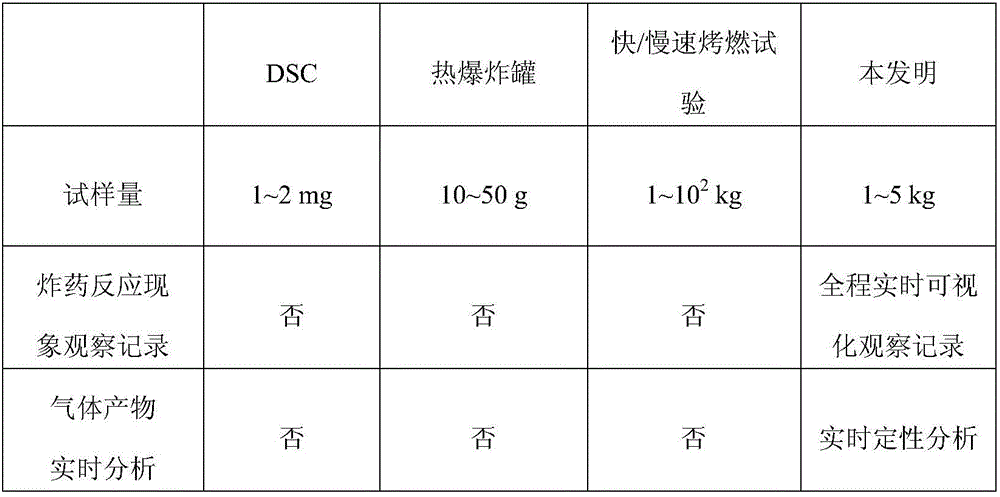

A technology for analyzing devices and gas products, which is applied to analyzing gas mixtures, measuring devices, analyzing materials, etc., and can solve the problems of inability to observe reaction phenomena, small sample size, and inability to observe subtle phenomena.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

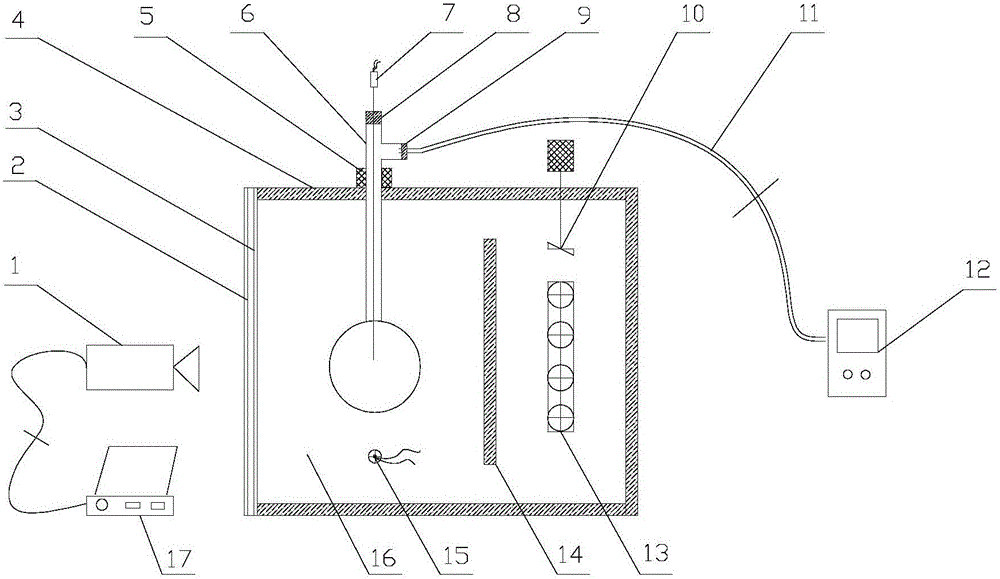

[0015] Attached below figure 1 And embodiment the present invention is described further.

[0016] 1.1 Manufacture of the present invention

[0017] The oven-burning box (16) of the present invention measures 70cm (length)×60cm×60cm, the overall heat-resistant temperature of the box is not less than 300°C, the temperature control accuracy is 0.1-10°C / min, and the heat preservation accuracy is ±1°C. HD camera (1) recording resolution ≥ 720P. The gas analyzer (12) can realize the addition and combination of gas detection sensors according to different explosives to be tested.

[0018] 1.2 Assembly of the present invention

[0019] Sample assembly: put the explosive powder to be tested into the round bottom flask (6), shake gently to make the assembled explosive particles as dense as possible, and limit the explosive sample to the inner mouth of the throat of the round bottom flask. After the sample assembly is completed, put the round-bottomed flask (6) into the reserved sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com