Mold manufacture automatic production control system and method

A technology of automatic control and mold manufacturing, applied in the direction of general control system, control/regulation system, program control, etc., to achieve the effect of simple design structure, optimized production process, and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

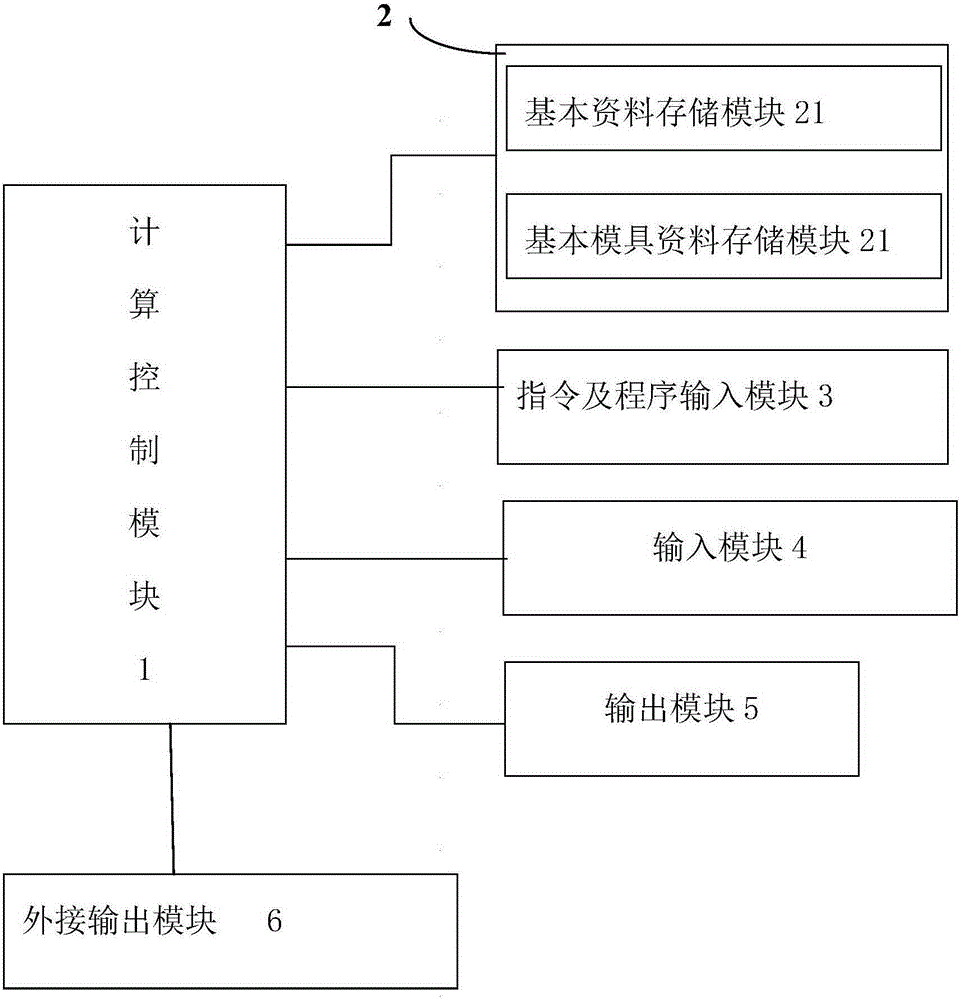

[0016] The present invention is an automatic control system and method suitable for mold manufacturing enterprises, see figure 1 As shown, the system of the present invention includes: a calculation control module 1, which uses a computer as the main body of calculation control, and is responsible for data retrieval, control and calculation processing of the system;

[0017] The data storage module 2, the data storage module 2 inputs and stores relevant basic data information in the computer in the form of a database or a form, and the basic data information module at least includes: a basic data storage module 21 and a basic mold data storage module 22;

[0018] Instruction and program input module 3, the instruction and program input module 3 inputs corresponding instructions and operation programs to the computer control module 1;

[0019] Input mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com