Hole diameter error modified compensation method based on screw milling hole

A technology of aperture error and helical milling, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of large aperture and error of assembly holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0031] In this embodiment, the design diameter of the assembly hole to be processed is

[0032] A method for correcting and compensating hole diameter errors based on helical milling, comprising the following steps:

[0033] Step 1: Establish a standard hole 3D model of the assembly hole;

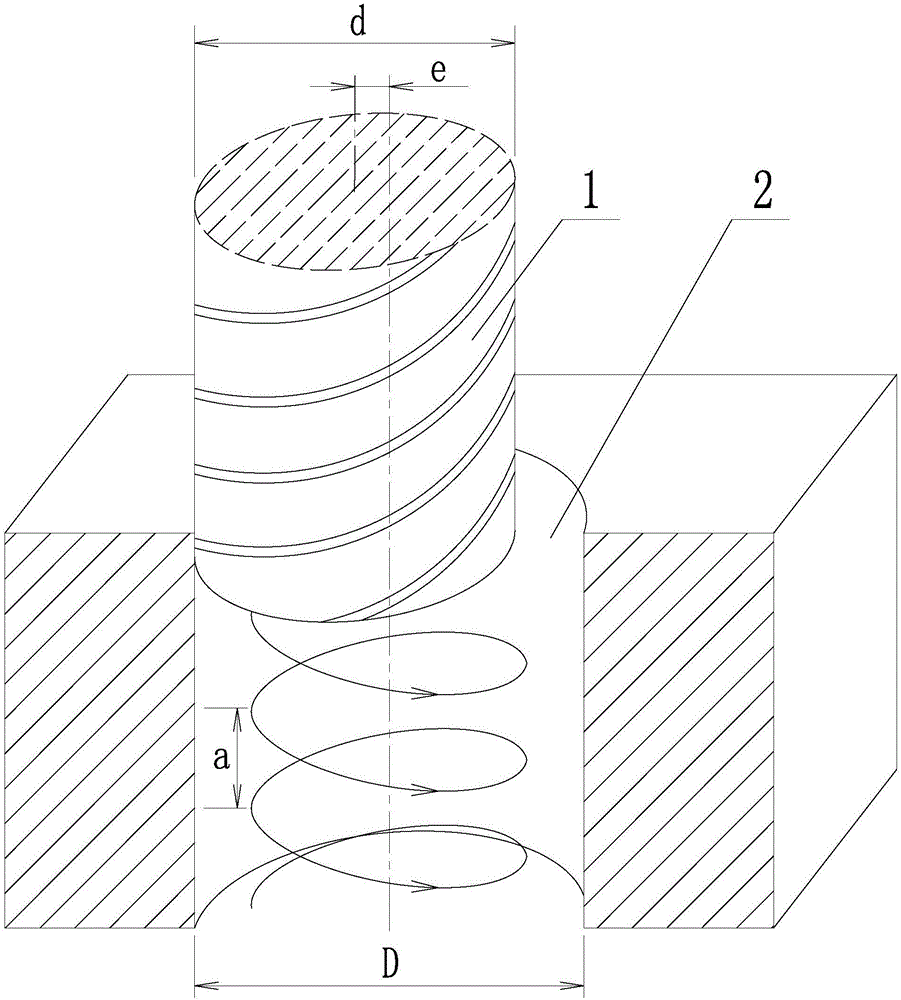

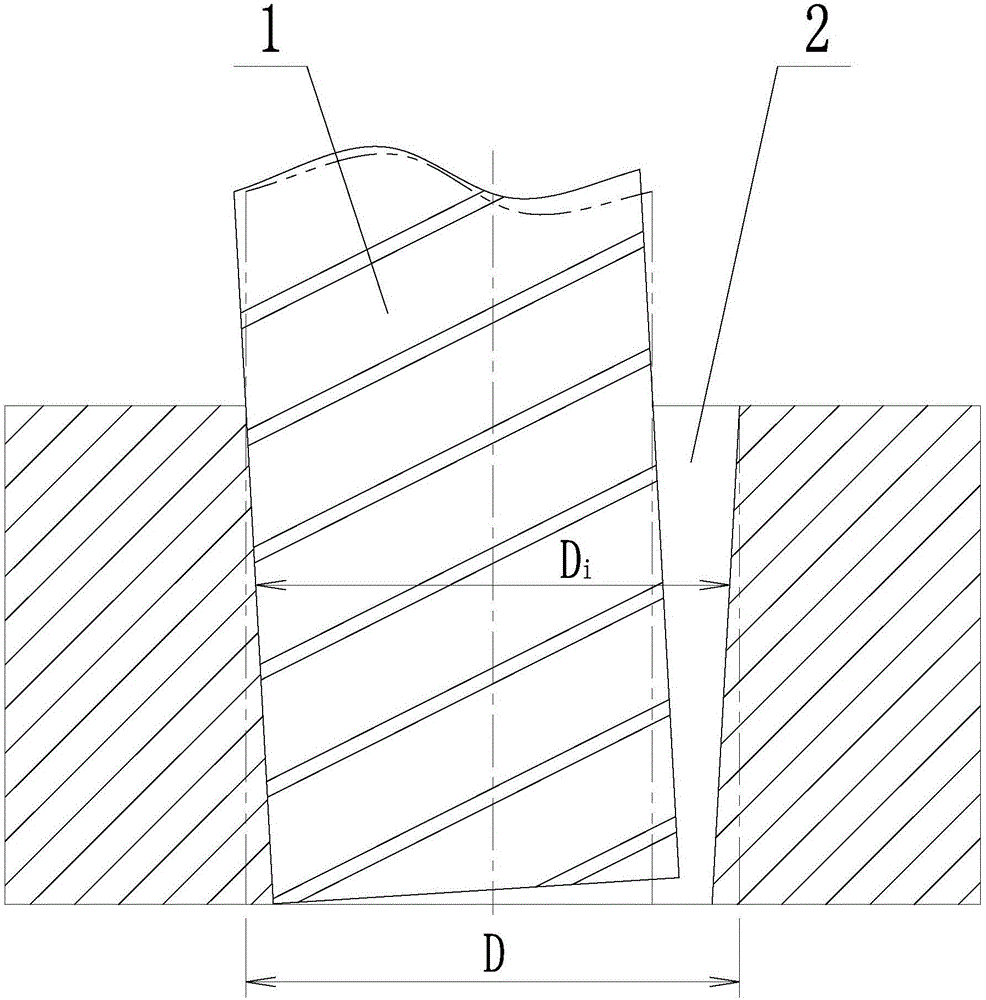

[0034] Step 2: Select a processing tool and set processing parameters; in this embodiment, the tool is a solid carbide double-tooth end mill, the diameter of the tool is 4mm, and the processing parameters include: the rotation speed of the tool is 3000r / min, the revolution speed of the tool is 10r / min, the eccentric distance between the axis of the tool and the axis of the assembly hole is 0.5mm, and the feed for one revolution of the tool is 0.5mm;

[0035] Step 3: Trial manufacture an assembly hole with the selected machining tool under the set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com