A supercapacitor discharge circuit and new energy vehicle

A supercapacitor and discharge circuit technology, applied in electric vehicles, battery circuit devices, current collectors, etc., can solve the problems of high price, slow discharge speed, low safety, etc., and achieve low cost, simple structure, and improved discharge efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

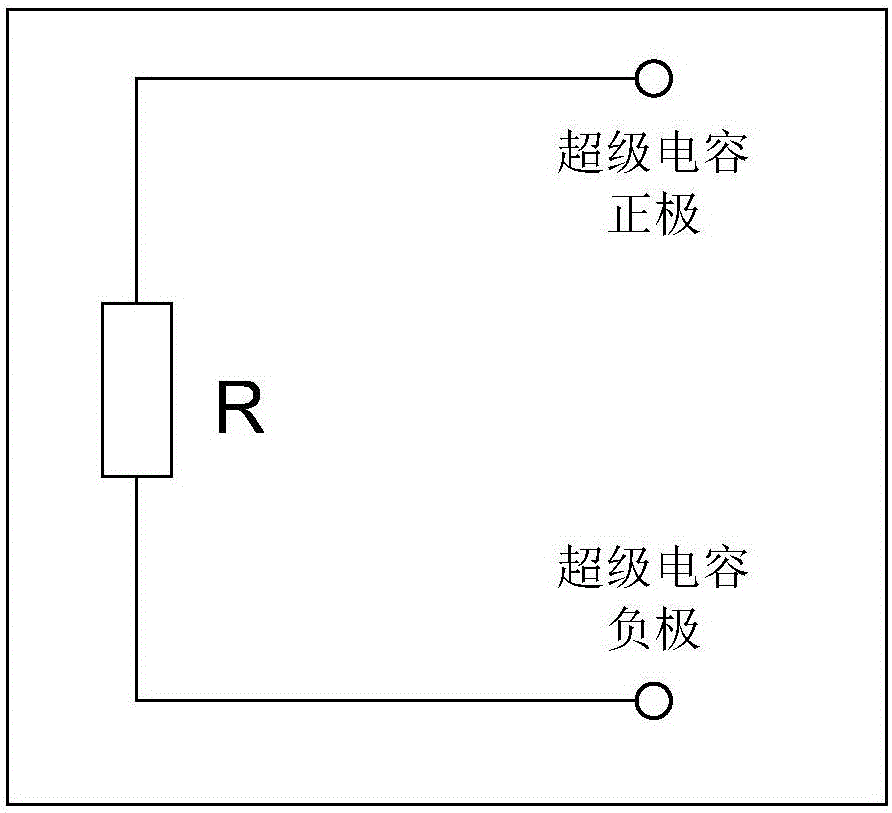

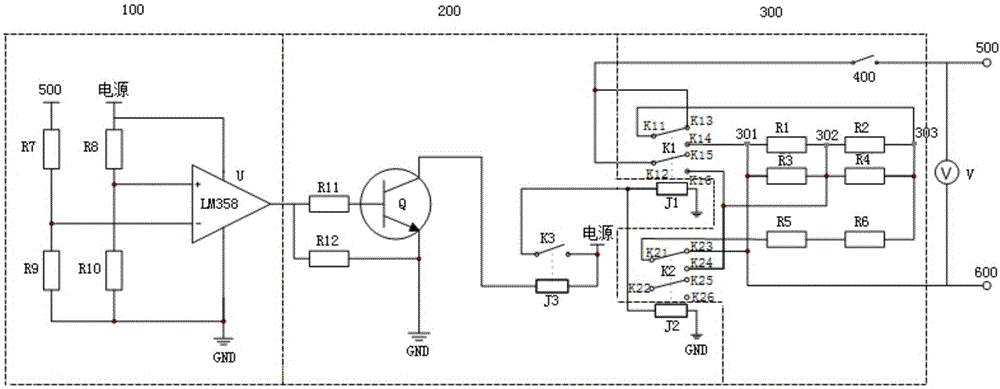

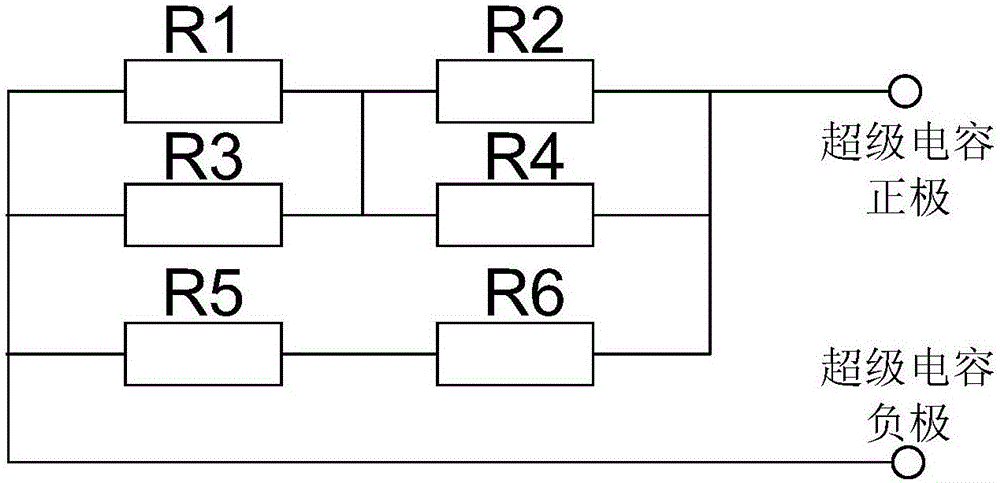

[0024] figure 2 It is the circuit diagram of the supercapacitor discharge circuit of the present invention. The supercapacitor discharge circuit includes a voltage comparison unit 100, a discharge control unit 200, a discharge resistance unit 300, a main switch 400, a positive interface 500 and a negative interface 600, wherein the voltage comparison unit 100, the discharge control unit 200 and the discharge resistance The units 300 are connected in sequence; the discharge control unit 200 controls the discharge resistance unit 300 to form different resistance values according to the level output by the voltage comparison unit 100; the discharge resistance unit 300 includes a first double pole double throw switch K1, the second double pole double throw switch K2 and the first resistor R1 to the sixth resistor R6, the first resisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com