Total heat recovery independent drive multi-effect distillation process utilizing condensed steam source heat pump

A technology with full heat recovery and independent drive, applied in heating water/sewage treatment, chemical instruments and methods, seawater treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

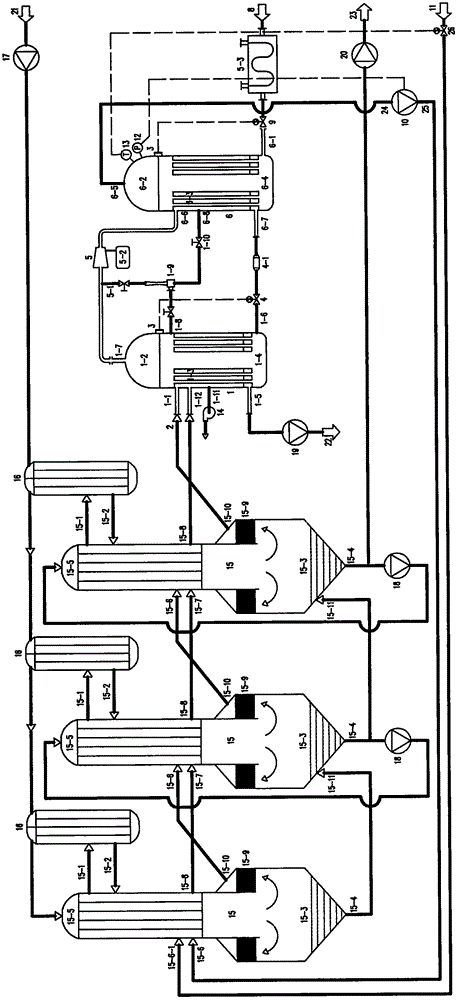

[0067] Attached figure 1 As shown, the description is as follows: It is a siphon circulation countercurrent heat rising film evaporator 1 made of carbon steel with an evaporation return capacity of 4050kW, vertical arrangement, and a stainless steel tube with a diameter of 200mm / wall thickness 2.5mm / length 200mm. Condensation inlet 1 -1; Cylindrical separation chamber 1-2 with diameter 1200mm / height 800mm; ring distribution of vertical siphon heat pipe clusters 1-3 with outer diameter 1200mm / inner diameter 840mm / height 2000mm / pipe diameter 19mm; diameter 1200mm / height 300mm Cylindrical shunt cavity 1-4; stainless steel tube condensate outlet 1-5 with diameter 40mm / wall thickness 1.5mm / length 60mm; copper tube liquid heat pump inlet 1-6 with diameter 60mm / wall thickness 1.5mm / length 60mm ;Diameter 120mm / wall thickness 1.5mm / length 120mm copper tube gaseous heat pump outlet 1-7; diameter 12mm / wall thickness 0.9mm / length 20mm oil suction port 1-8; interface diameter 12mm / wall thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com