A kind of nano thermal insulation board capable of releasing negative oxygen ions and preparation method thereof

A technology of negative oxygen ions and thermal insulation panels, which is applied in the field of building panels, can solve problems such as easy condensation on the inner wall, and achieve the effect of avoiding condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

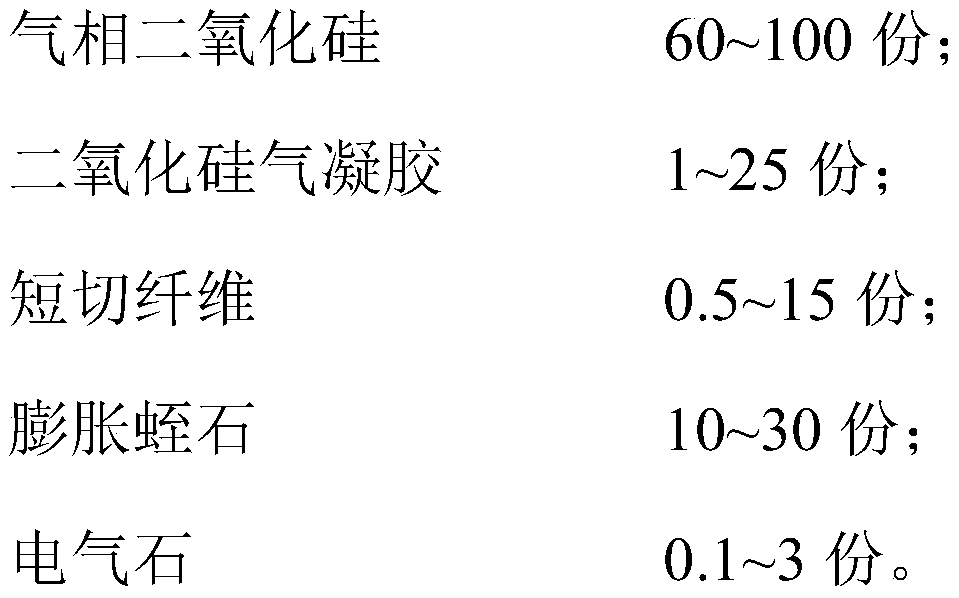

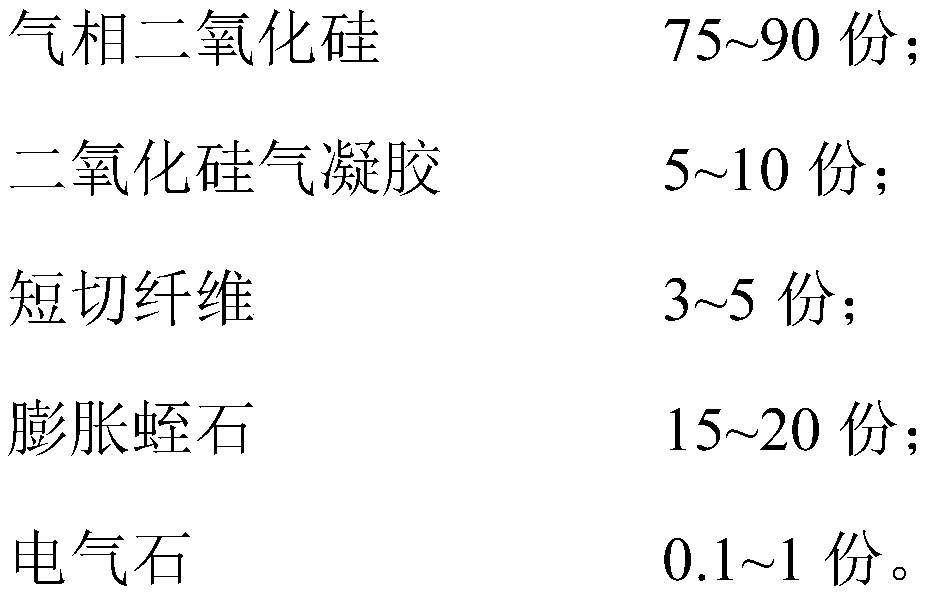

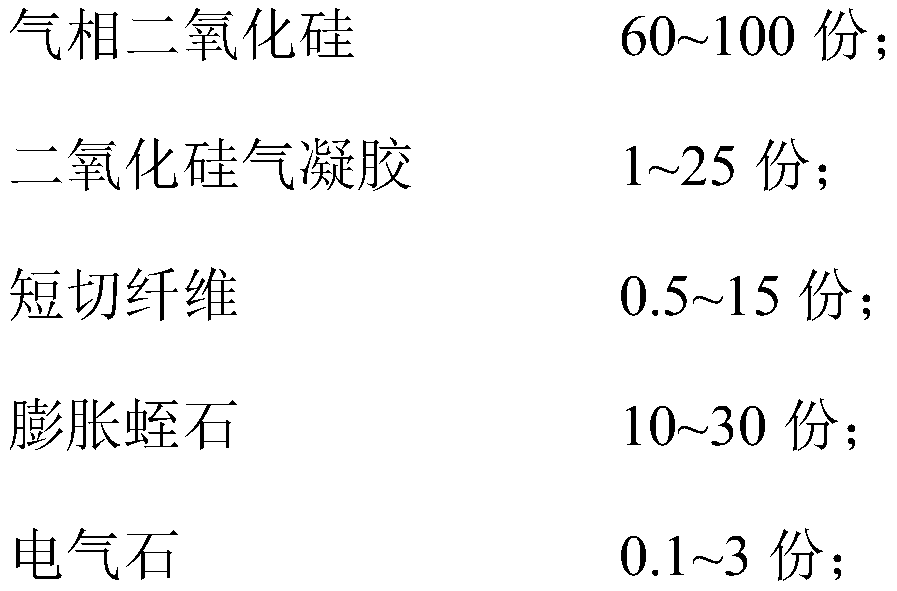

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a method for preparing a nano-insulation panel capable of releasing negative oxygen ions, comprising the following steps:

[0032] (1) 15Kg expanded vermiculite and 0.5Kg tourmaline are put into the blender, and mixed to form the first mixture;

[0033] (2) Add 40Kg fumed silica and 2Kg chopped fibers to the first mixture, and then add 1.67Kg silica airgel after stirring for 10 minutes under sealed conditions, and continue to stir for 30 minutes under sealed conditions to form the second mixture. mixture;

[0034] (3) Add the remaining 40Kg fumed silica and 2Kg chopped fibers to the second mixture, stir for 20min under sealed conditions, then add the remaining 3.33Kg of the silica airgel, and continue under sealed conditions Stir for 30min to obtain a premix;

[0035] (4) According to the product specifications, weigh an appropriate amount of the above premix and add it to the press, and control the pressure at 10MPa to apply pressure slowly a...

Embodiment 2

[0039] This embodiment provides a method for preparing a nano-insulation panel capable of releasing negative oxygen ions, comprising the following steps:

[0040](1) 20Kg expanded vermiculite and 0.1Kg tourmaline are put into the blender, and mixed to form the first mixture;

[0041] (2) Add 45Kg fumed silica and 2.5Kg chopped fibers to the first mixture, and then add 3Kg of silica airgel after stirring for 20 minutes under sealed conditions, and continue to stir for 20 minutes under sealed conditions to form the second mixture. mixture;

[0042] (3) Add the remaining 45Kg fumed silica and 2.5Kg chopped fibers to the second mixture, stir for 10 minutes under sealed conditions, then add the remaining 6Kg of the silica airgel, and continue under sealed conditions Stir for 45min to obtain a premix;

[0043] (4) According to the product specifications, weigh an appropriate amount of the above-mentioned premix and add it to the press, and control the pressure to 5MPa to apply pre...

Embodiment 3

[0047] This embodiment provides a method for preparing a nano-insulation panel capable of releasing negative oxygen ions, comprising the following steps:

[0048] (1) 10Kg expanded vermiculite and 1Kg tourmaline are put into the blender, and mixed to form the first mixture;

[0049] (2) Add 30Kg of fumed silica and 1.5Kg of chopped fibers to the first mixture, stir for 15 minutes under sealed conditions, then add 0.33Kg of silica airgel, and continue to stir for 40 minutes under sealed conditions to form the first mixture. Two mixtures;

[0050] (3) Add the remaining 30Kg fumed silica and 1.5Kg chopped fibers to the second mixture, stir for 30min under sealed conditions, then add the remaining 0.67Kg of the silica aerogel, and continue under sealed conditions Down stirring 60min, obtains premix;

[0051] (4) According to the product specifications, weigh an appropriate amount of the above-mentioned premix and add it to the press, and control the pressure at 15MPa to apply pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com