Anticorrosive heat-insulating coating and preparation method thereof

A technology of heat-insulating coatings and preservatives, applied in anti-corrosion coatings, reflective/signal coatings, coatings, etc., can solve problems such as troubles in use and generation of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

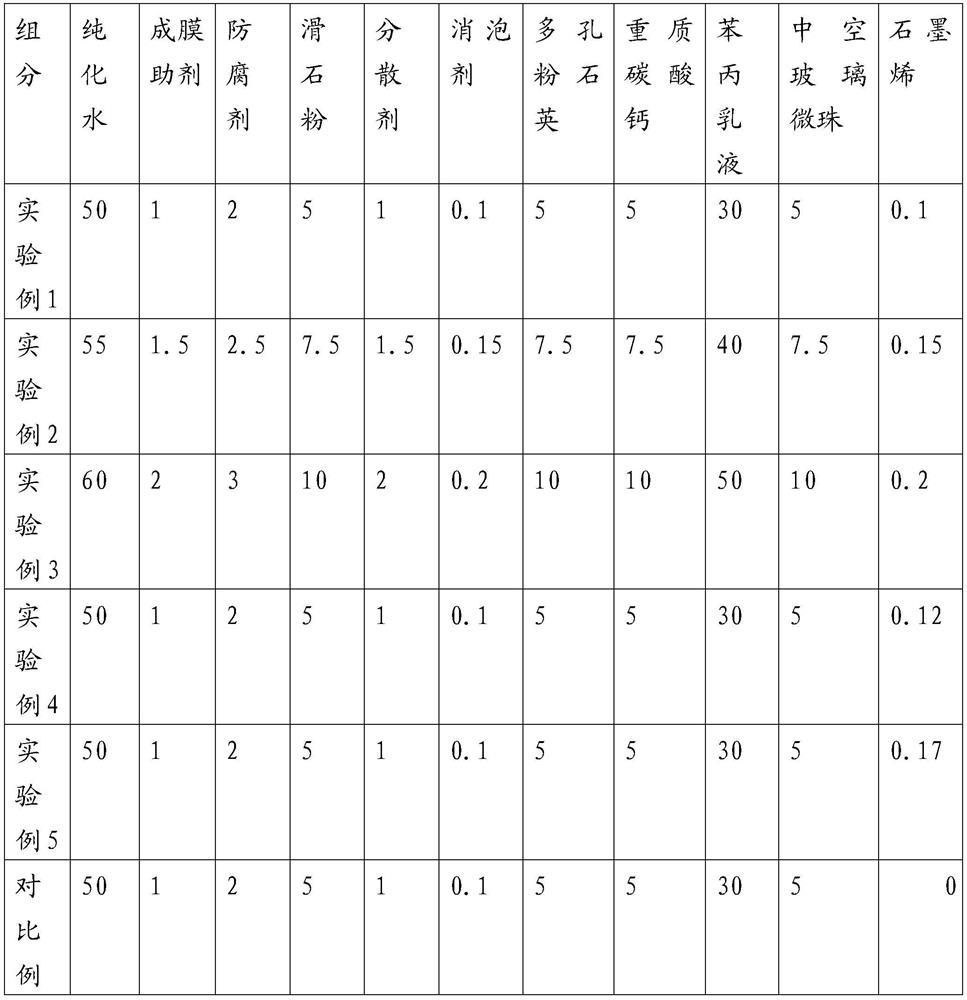

[0017] An anti-corrosion and heat-insulating coating provided in this embodiment comprises the following components: 50-60 parts by weight of purified water; 1-2 parts by weight of film-forming aid; 2-3 parts by weight of preservative; 1-2 parts by weight of dispersant; 0.1-0.2 parts by weight of defoamer; 5-10 parts by weight of porous powder quartz; 5-10 parts by weight of heavy calcium carbonate; 30-50 parts by weight of styrene-acrylic emulsion; 5-10 parts by weight of beads; 0.1-0.2 parts by weight of graphene.

[0018] The preparation method of the anticorrosion and heat-insulating coating provided by the present embodiment comprises the following steps:

[0019] S1: Stir the purified water, film-forming aids, preservatives, and dispersants evenly;

[0020] S2: Under high-speed stirring, add talcum powder, defoamer, porous powdered quartz, ground calcium carbonate, hollow glass microspheres and graphene to S1, control the particle size below 50 μm, and finally add styre...

no. 2 example

[0024] The graphene in this embodiment is supported on the porous powdered quartz, and the graphene is supported on the porous powdered quartz by sintering.

[0025] The graphene is loaded on the porous powder quartz, and the graphene is loaded on the porous powder quartz by sintering; the method includes the following steps: the graphene powder and the porous powder quartz are mixed and loaded into a mold, and the sintering process is carried out in a sintering furnace Sintering, the sintering temperature is 900°C, the sintering is carried out under vacuum conditions, the sintering pressure is 50MPa, the sintered material is crushed and ground into a powder state material.

[0026] Compared with the common mixing method, using the graphene of the material of this embodiment, in the actual test, the resistivity error of different detection points in multiple positions is reduced, which shows that the dispersion of graphene in the powder is strengthened, This relies on the impr...

no. 3 example

[0028] The graphene in this embodiment is coated on the porous powder quartz, and the surface of the graphene is condensed with the surface-aminated porous powder quartz to form a modified material.

[0029] Graphene is coated in porous powder quartz, and porous powder quartz is the porous powder quartz of surface amination, and the material that Graphene surface forms with the porous powder quartz amide condensation of surface amination; The method comprises the following steps: obtain surface oxygen-containing The graphene of the surface amination treatment of porous powder quartz is obtained, and the graphene with oxygen-containing groups on the surface is reacted and locked with the porous powder quartz of the surface amination treatment, so that the graphene and the porous powder quartz are passed through the amide bond. combine to form a stable structure.

[0030] The coating component obtained in this example, the component in the first example, when testing the resisti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com