All-water one-step flexible thermal insulation pipe material and preparation method thereof

A thermal insulation pipe and step method technology, which is applied in the field of all-water one-step flexible thermal insulation pipe material and its preparation, can solve the problems of destroying the ozone layer of the atmosphere, deteriorating thermal insulation performance, high foam brittleness, etc., so as to improve production stability and reduce reaction heat. , the effect of fine cell structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Preparation of modified isocyanates:

[0033] Stir butanediol and polyethylene glycol at a temperature range of 100±10°C, vacuum dehydrate for 3 hours, cool down to 55°C, add a mixture of polymethylene polyphenyl polyisocyanate and diphenylmethane diisocyanate, at 85 ℃ reaction to prepare modified isocyanate, which is packaged for later use.

[0034] All used in the examples are parts by mass.

Embodiment 1

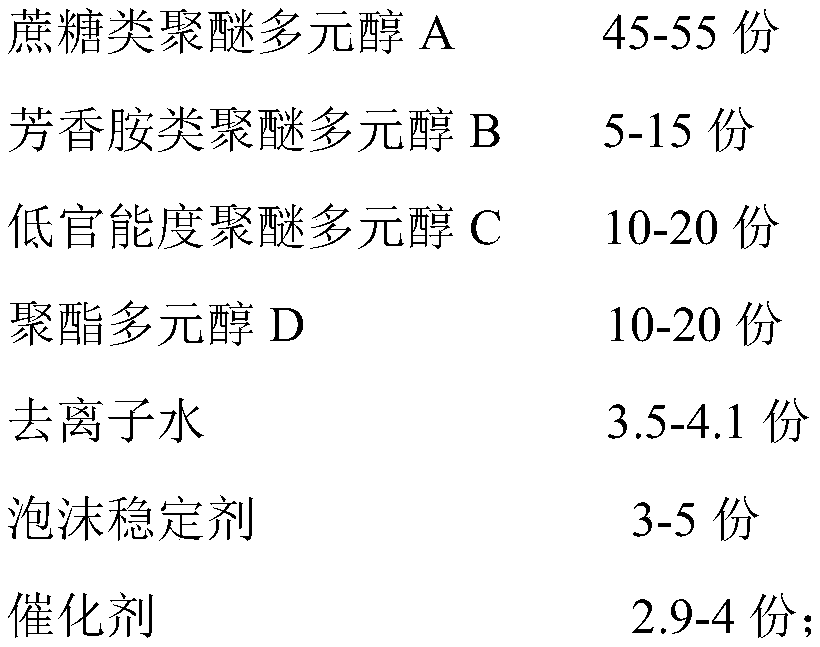

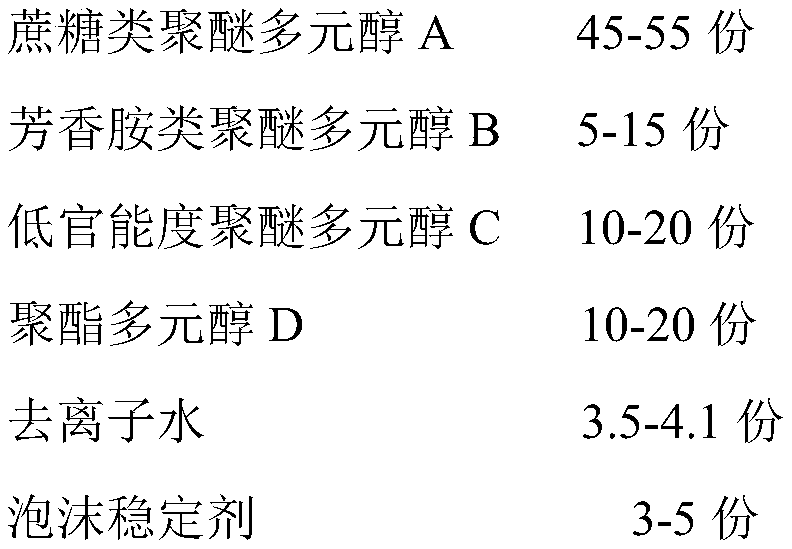

[0036] (1) Preparation of component A: Weigh sucrose polyether polyol A (functionality 5.1, hydroxyl value 340mg KOH / g, viscosity at 25°C 2360mPa.s, starting with sucrose and glycerin) agent) 50 parts, R403715 parts, C310 14 parts, PS-3152 10 parts, deionized water 4.0 parts, B8534 3 parts, pentamethyldiethylenetriamine 1 part, triethylenediamine 1.5 parts, potassium acetate 1.1 part, 0.4 part of 1,3,5-tris(dimethylaminopropyl)hexahydrotriazine, stir and mix at room temperature, stir for 1 hour, take it out for inspection, and if it meets the set foaming parameters, it can be packed into a bucket for later use;

[0037] (2) Preparation of component B: weigh 70 parts of polymethylene polyphenyl polyisocyanate and 30 parts of modified isocyanate, stir evenly, and package for later use;

[0038] (3) Mixing and curing: Mix A component and B component in a foaming machine according to the mass ratio of A:B=1:1.5.

[0039] The indicators of test foam products are as follows:

[00...

Embodiment 2

[0048] (1) Preparation of component A: Weigh sucrose polyether polyol A (functionality 5.3, hydroxyl value 330mg KOH / g, viscosity at 25°C 2260mPa.s, starting with sucrose and propylene glycol agent) 43 parts, R403710 parts, C310 20 parts, PS-3152 15 parts, deionized water 3.5 parts, B8534 5 parts, bis(dimethylaminoethyl) ether 0.2 parts, N,N-dimethylcyclohexylamine 0.7 parts, 1.3 parts of dimethylbenzylamine, and 1.3 parts of potassium isooctanoate are stirred and mixed at room temperature, stirred for 0.5-1.5 hours, taken out for inspection, and can be packed into barrels for later use if they meet the set foaming parameters;

[0049] (2) Preparation of component B: weigh 90 parts of polymethylene polyphenyl polyisocyanate and 10 parts of modified isocyanate, stir evenly, and package for later use;

[0050] (3) Mixing and curing: Mix A component and B component in a foaming machine according to the mass ratio of A:B=1:1.3.

[0051] The indicators of test foam products are as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com