Servo hydraulic device

A technology of hydraulic station and hydraulic oil tank, which is applied in the direction of fluid pressure actuation device, servo meter circuit, fluid pressure actuation system components, etc., and can solve the problems of high cost, small displacement range, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

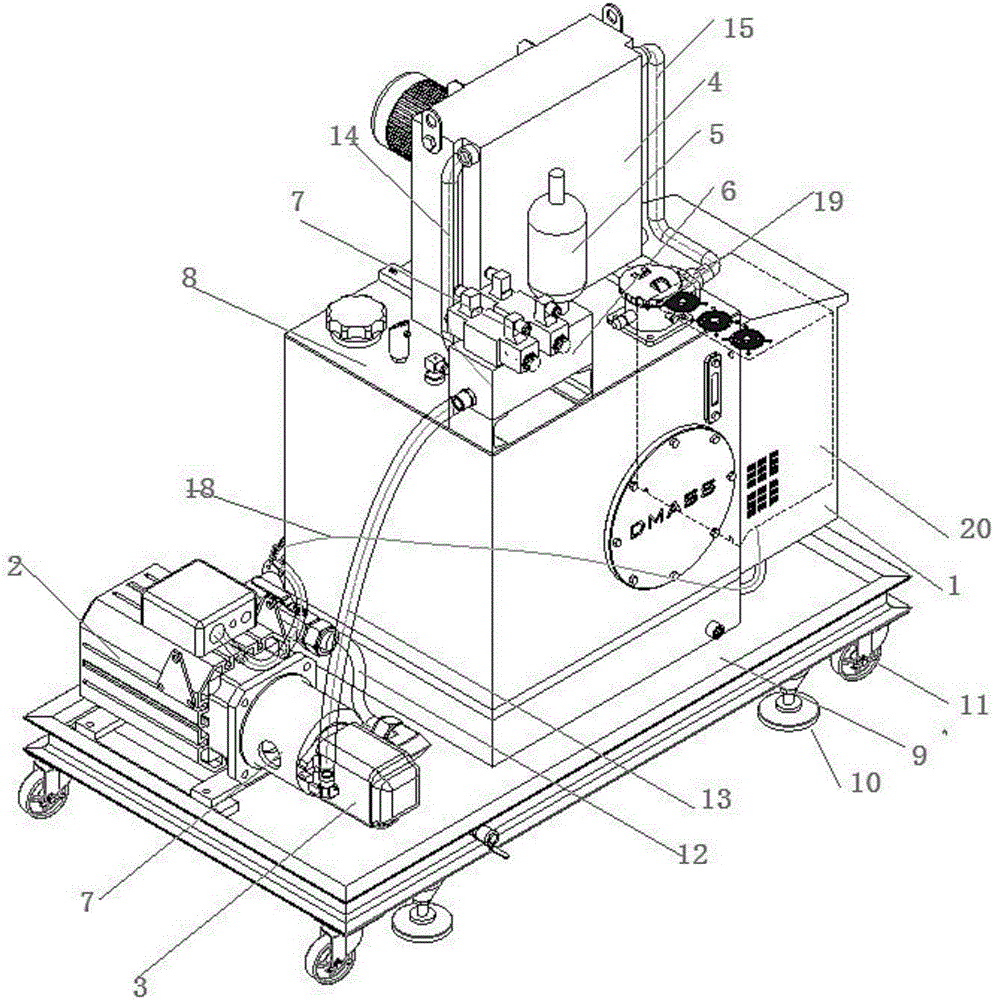

[0010] like figure 1 Shown is a servo oil pump device, a servo oil pump device, including a servo driver 1, a servo motor 2, a silent gear pump 3, an air cooler 4, a bladder accumulator 5, an integrated oil circuit board 6, a solenoid valve 7, Hydraulic oil tank 8, tray 9, fixed feet 10, universal wheels 11, low-pressure hose 12, high-pressure hose 13, first seamless steel pipe 14, second seamless steel pipe 15, solenoid valve 16, elastic coupling and bell Cover bracket 17, cable 18, oil return filter 19, the servo motor 2 is connected with the silent gear pump 3 through the elastic coupling 17, and the silent gear pump 3 is connected with the hydraulic oil tank 8 through the low-pressure hose 12, the The hydraulic oil tank 8 is connected to the electric control box 20, the electric control box 20 is provided with a servo driver 1, the servo driver 1 is connected to the servo motor 2 through a cable 18, and the silent gear pump 3 is connected to the integrated oil pump through...

Embodiment 2

[0017] like figure 1 Shown is a servo oil pump device, a servo oil pump device, including a servo driver 1, a servo motor 2, a silent gear pump 3, an air cooler 4, a bladder accumulator 5, an integrated oil circuit board 6, a solenoid valve 7, Hydraulic oil tank 8, tray 9, fixed feet 10, universal wheels 11, low-pressure hose 12, high-pressure hose 13, first seamless steel pipe 14, second seamless steel pipe 15, elastic coupling and bell bracket 17, Cable 18, oil return filter 19, the servo motor 2 is connected to the silent gear pump 3 through the elastic coupling 17, the silent gear pump 3 is connected to the hydraulic oil tank 8 through the low-pressure hose 12, and the hydraulic oil tank 8 is connected to the The electric control box 20 is connected, and the electric control box 20 is provided with a servo driver 1, and the servo driver 1 is connected to the servo motor 2 through a cable 18, and the silent gear pump 3 is connected to the integrated oil circuit board 6 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com