Circulating cooling water supply system for multiple hypersonic speed testing devices

A technology of circulating cooling water and test equipment, which is applied in household refrigeration devices, applications, household appliances, etc., to achieve the effects of low utilization rate, power saving, and resource waste avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

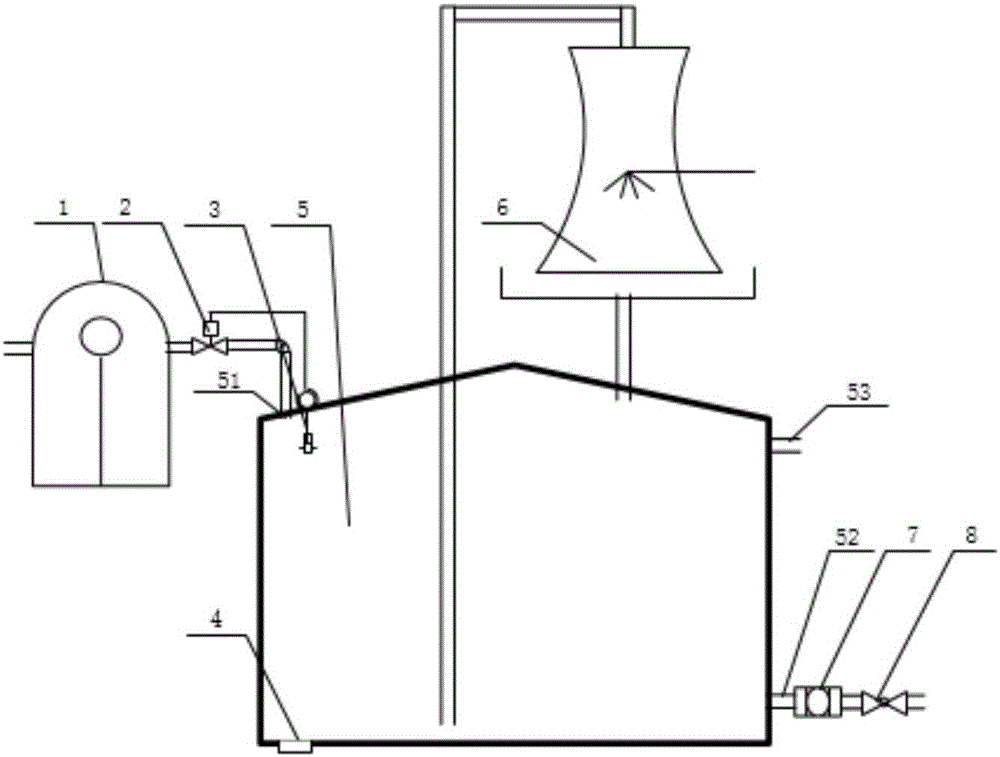

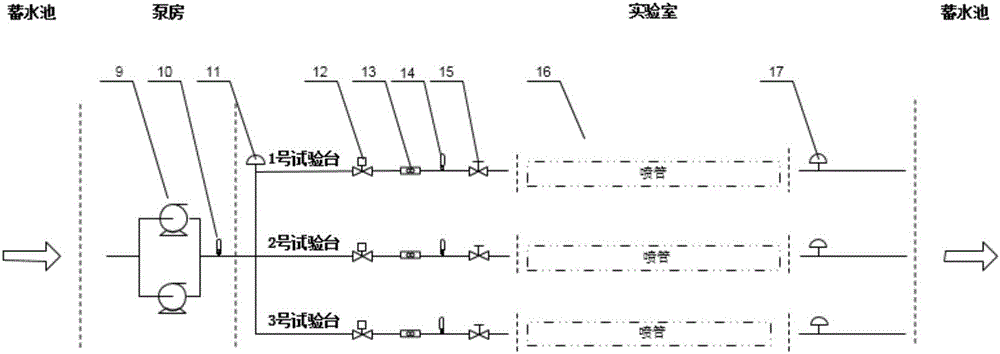

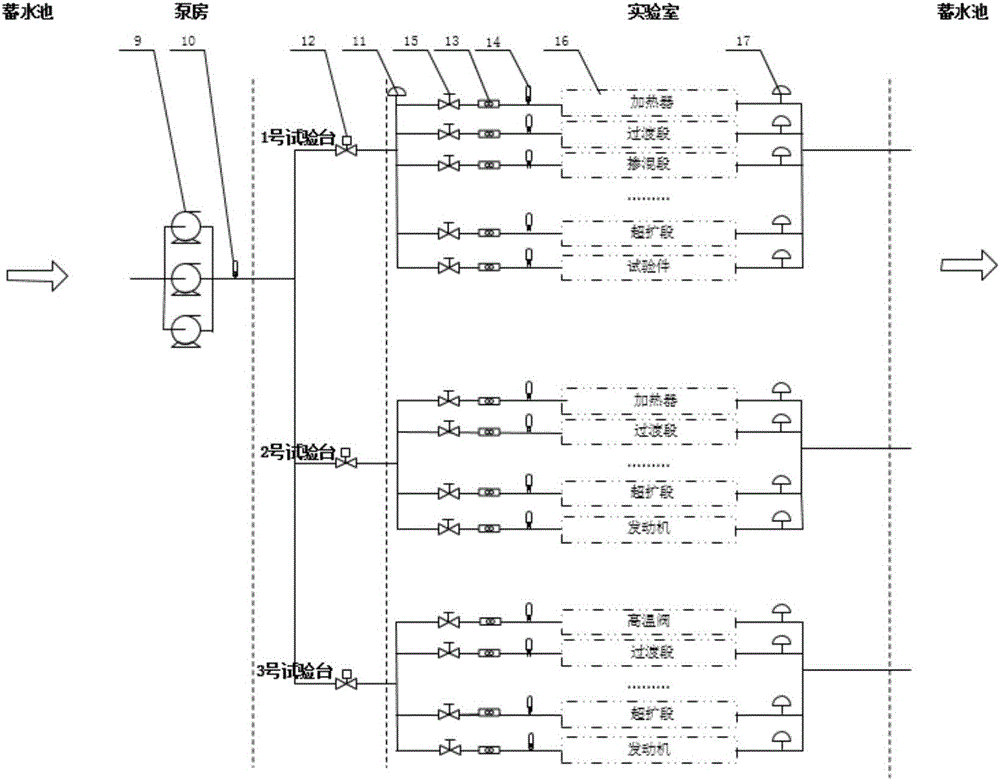

[0025] The present invention provides as attached Figure 1-3 A circulating cooling water supply system for multiple hypersonic test equipment is shown, including tap water purification equipment 1, a reservoir 5, a water pump 9, multiple cooling units 16 for cooling hypersonic test equipment, and a PLC The control room of the main engine and the pipe network used to connect the tap water purification equipment 1, the reservoir 5, the water pump 9, and the cooling unit 16; the reservoir has a water injection port 51, a water outlet 52 and a water return port 53, and the water injection port 51 is connected to tap water In the purification device 1 , the water return port 53 is connected to the outlet of the cooling unit 16 , and the water pump 9 is located between the inlet of the cooling unit 16 and the water outlet 52 .

[0026] Further, the tap water purification equipment 1 adopts the method of ion exchange resin to produce purified water, and judges the process of automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com