Electronic Operating Data Memory for a Rotationally Operating Machine

A technology of operating data and rotating work, applied in memory systems, electrical digital data processing, record carriers used by machines, etc., can solve the problems of changing type signs, dirt, corrosion, etc., and achieve the effect of easy readability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

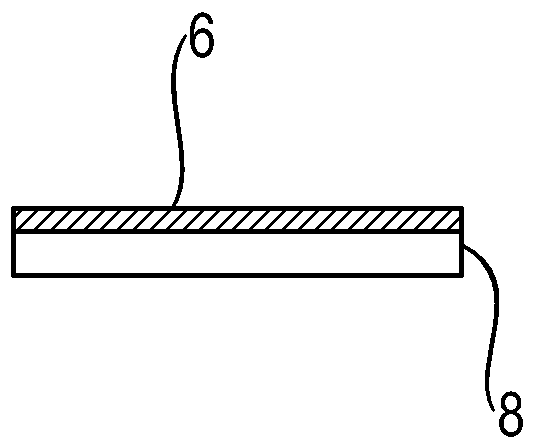

[0040] exist figure 1 The electronic operating data storage unit 1 according to the invention is shown in FIG. A common type label 6 is likewise arranged on the housing 4 .

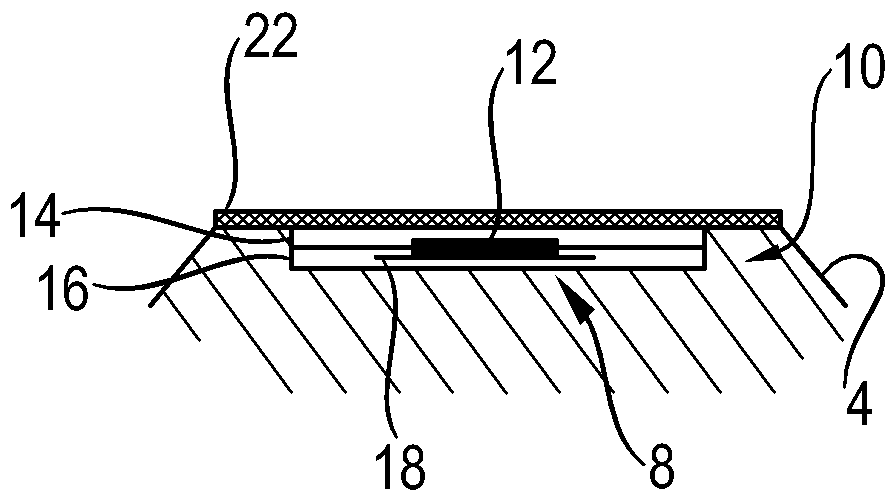

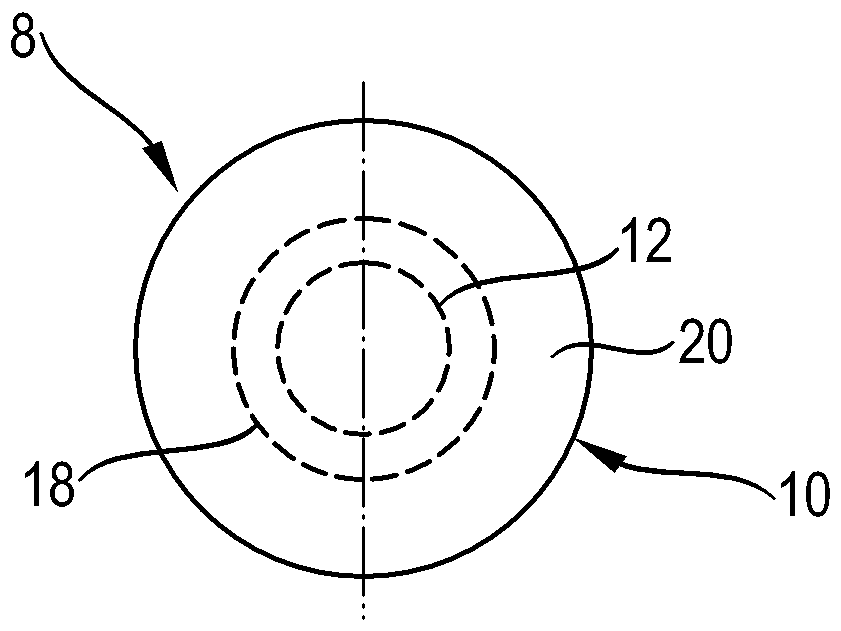

[0041] The electronic operating data store 1 contains a transmit / receive device 8 which is designed as a transponder tag. as in Figure 2a As shown in , the transponder tag 8 contains a transponder housing 10 and an RFID transponder 12, which is arranged between an upper part 14 of the transponder housing 10 and a lower part 16 of the transponder housing. Between the RFID transponder 12 and the lower part 16 is arranged a shielding device 18 designed as a shielding film, whereby the RFID transponder 12 does not come into direct contact with the lower part 16 but passes through the shielding film 18 . The shielding film 18 protrudes radially beyond the RFID transponder 12 , but it can alternatively be closed radially by the RFID transponder 12 . The shielding film 18 consists of a polymer doped with fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com