Fructus lycii processing methodn

A processing method and technology for wolfberry fruit, which are applied in the directions of pharmaceutical formulations, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of unacceptable market price of dried wolfberry fruit, loss of nutritional components of fresh wolfberry fruit, and inability to popularize widely, etc. Avoid blackening and mildew, save labor costs, and have good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

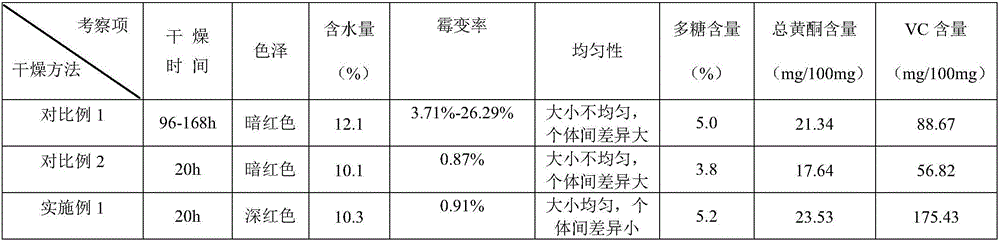

Embodiment 1

[0033] The place of origin of the fresh fruit of Lycium barbarum in Example 1 and Comparative Example 1 and Comparative Example 2 is Kongtan Village, Zhongning County, Ningxia.

[0034] Example 1

[0035] A processing method of wolfberry, the steps are:

[0036] 1) Dewaxing:

[0037] First prepare the edible alkali into an alkali solution with a concentration of 30g / L, then put the picked fresh medlars together with the basket into the alkali solution, soak for 20 seconds, remove the basket, and drain for 30 minutes.

[0038] 2) Preheat the drying room:

[0039] The drying room adopts a closed hot air circulation system. The drying room is purchased from Yangling Jinye Drying Equipment Co., Ltd. and is equipped with a coal-fired hot air stove, hot air pipe, temperature and humidity controller, combustion-supporting fan, circulation fan and damper.

[0040] First ensure that the furnace fire in the drying room is normal, the fan circuit is connected normally, and the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com