A 2-aminophenol-4-sulfonic acid production waste liquid modified sulfamic acid-based high-efficiency water reducer

A sulfamic acid-based, high-efficiency water-reducing agent technology is applied in the field of cement admixture production, which can solve the problems of high cost and weak practical applicability, reduce the cost of raw materials, realize waste utilization, and improve dispersing ability and water-reducing rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

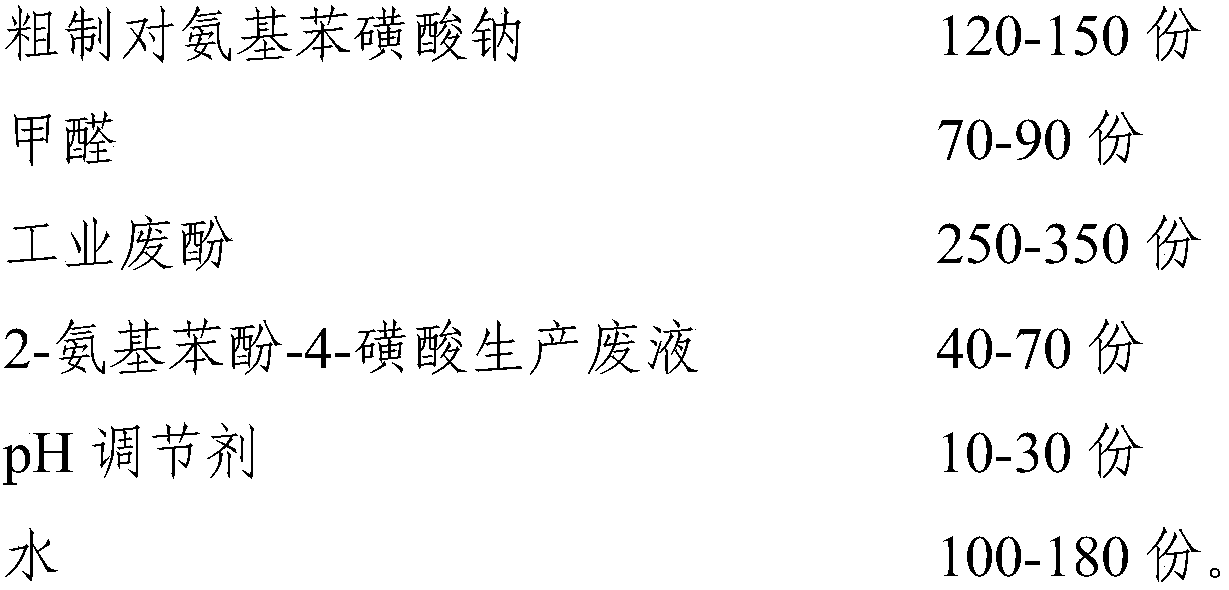

[0025] A 2-aminophenol-4-sulfonic acid production waste liquid modified aminosulfonic acid-based superplasticizer, comprising the following raw materials in parts by weight:

[0026]

[0027]

[0028] Its preparation method comprises the following steps:

[0029] (1) dissolving, filtering: add water in the reactor, then drop into crude sodium p-aminobenzenesulfonate and industrial waste phenol respectively, the reactor is heated to 80-85 ℃, stirred for no less than 1 hour, cooled, filtered Remove the solid slag particles and keep the filtrate for later use;

[0030] (2) addition: slowly add a pH regulator to the filtrate obtained in step (1), and adjust the pH of the solution to 8-9;

[0031] (3) polycondensation: the solution is warmed up to 90-95° C., slowly add formaldehyde solution dropwise to it, so that formaldehyde is dripped in 1.5-2 hours, and the temperature is kept for not less than 2 hours;

[0032] (4) Copolymerization: adding 2-aminophenol-4-sulfonic acid...

Embodiment 2

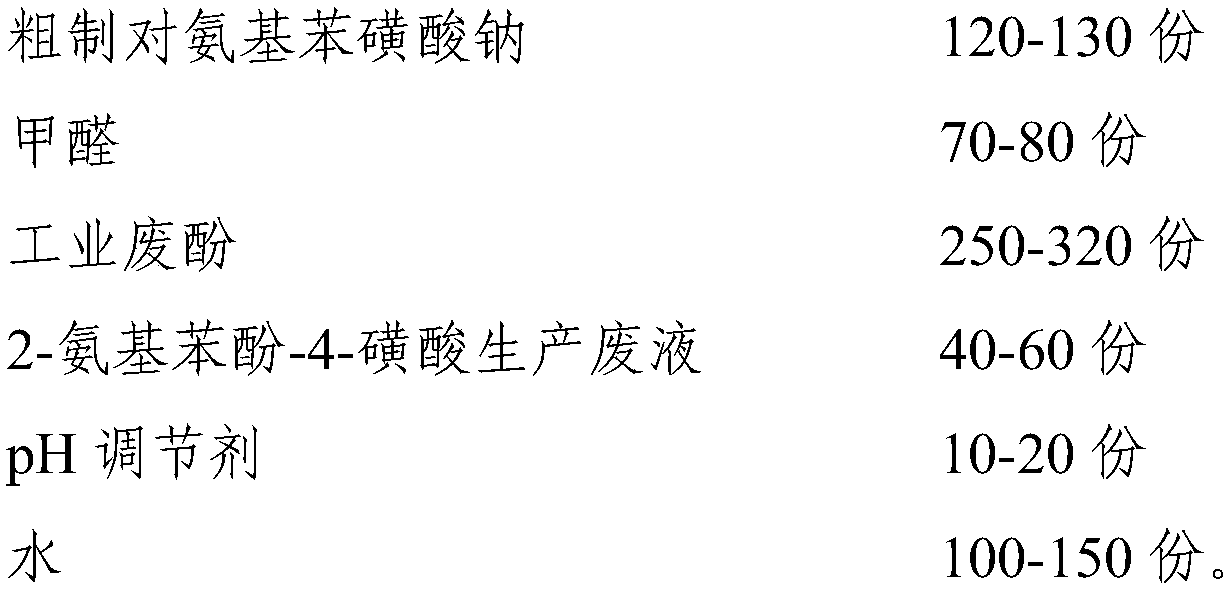

[0035] A 2-aminophenol-4-sulfonic acid production waste liquid modified aminosulfonic acid-based superplasticizer, comprising the following raw materials in parts by weight:

[0036]

[0037] The preparation method is the same as that in Example 1.

[0038] When in use, the water reducing agent can be mixed into the cement at 1.1 wt % of the weight of the cement.

Embodiment 3

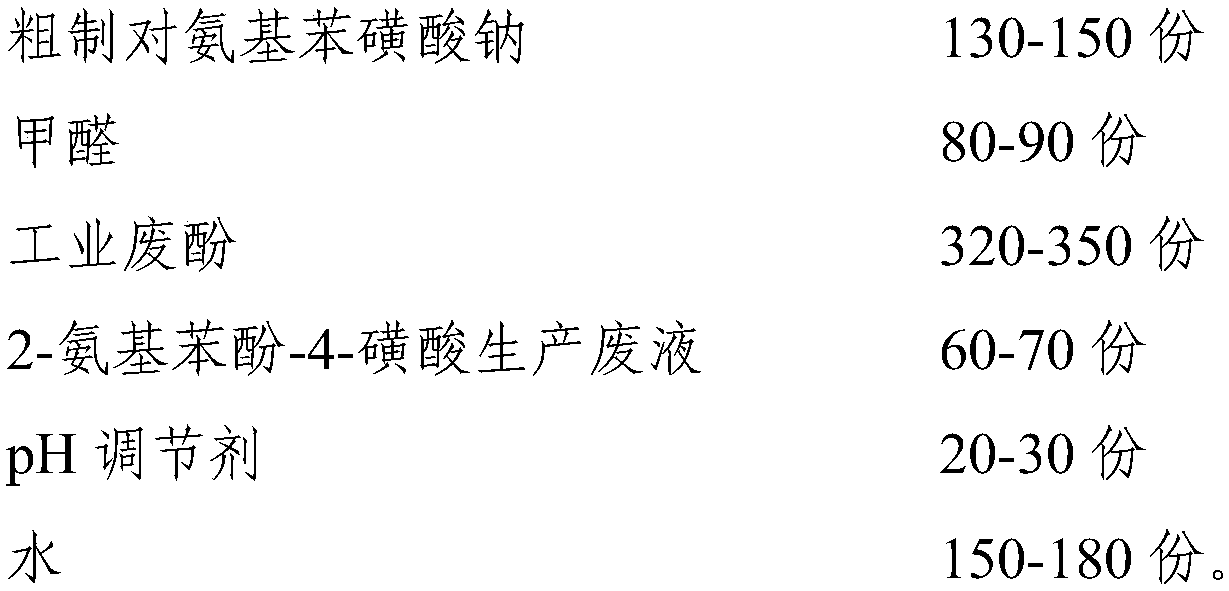

[0040] A 2-aminophenol-4-sulfonic acid production waste liquid modified aminosulfonic acid-based superplasticizer, comprising the following raw materials in parts by weight:

[0041]

[0042] The preparation method is the same as that in Example 1.

[0043] When in use, the water reducing agent can be mixed into the cement at 1.2 wt % of the weight of the cement.

[0044] The performance data of the water reducing agent prepared by using embodiment 1-3 are shown in the following table:

[0045]

[0046] As can be seen from the above table, compared with the test standard of the national standard "concrete admixture", the water-reducing agent prepared by Example 1-3 has higher water-reducing rate, lower air content, and lower 28d shrinkage ratio. Concrete has high compressive strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com