Cable material with high oil resistance and preparing method thereof

A cable material, high oil-resistant technology, applied in the field of oil-resistant cable materials, can solve the problem of unstable oil resistance of materials, achieve low cost, easy processing, and improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

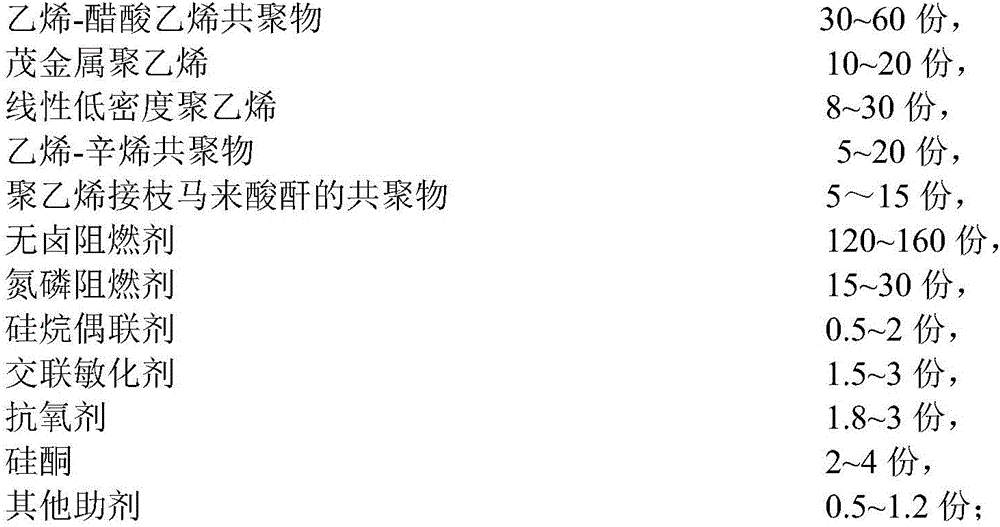

Method used

Image

Examples

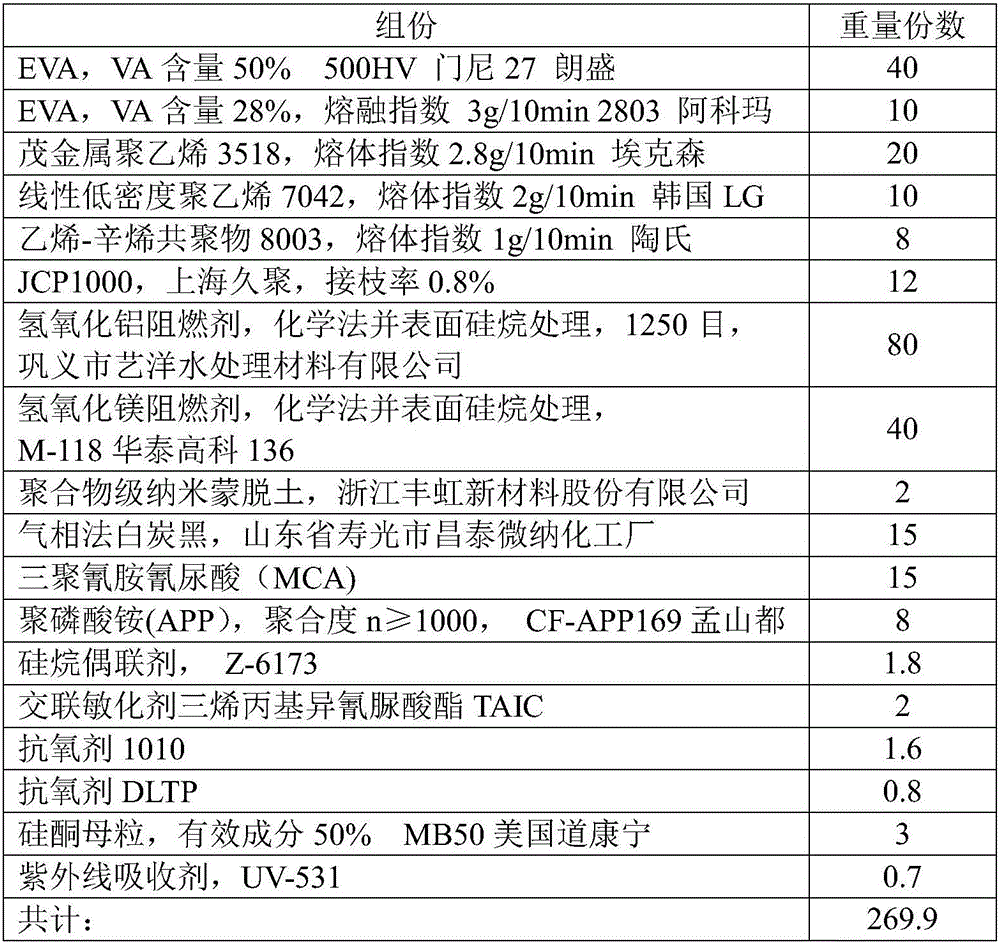

Embodiment 1

[0030] Embodiment 1: A kind of high oil resistant cable material, the material formula is as follows:

[0031]

[0032] The preparation method of above-mentioned high oil resistance cable material is as follows:

[0033] The first step: the copolymer of ethylene-vinyl acetate copolymer, metallocene polyethylene, linear low density polyethylene, ethylene-octene copolymer and polyethylene grafted maleic anhydride, and 2.5wt% of silicone and 2.5 Wt% of the halogen-free flame retardant was mixed in a high-speed mixer at a speed of 800rpm for 300 seconds, and then mixed and plasticized and granulated by a twin-screw granulator to obtain a masterbatch;

[0034] The second step: the masterbatch obtained in the first step, nitrogen and phosphorus flame retardants, silane coupling agents, crosslinking sensitizers, antioxidants, other processing aids, the remaining amount of halogen-free flame retardants and the remaining amount of Silicone, mixed in a high-speed mixer at a speed of...

Embodiment 2

[0040] Embodiment 2: A kind of high oil resistant cable material, the material formula is as follows:

[0041]

[0042] The preparation method of the above-mentioned high oil-resistant cable material is the same as in Example 1.

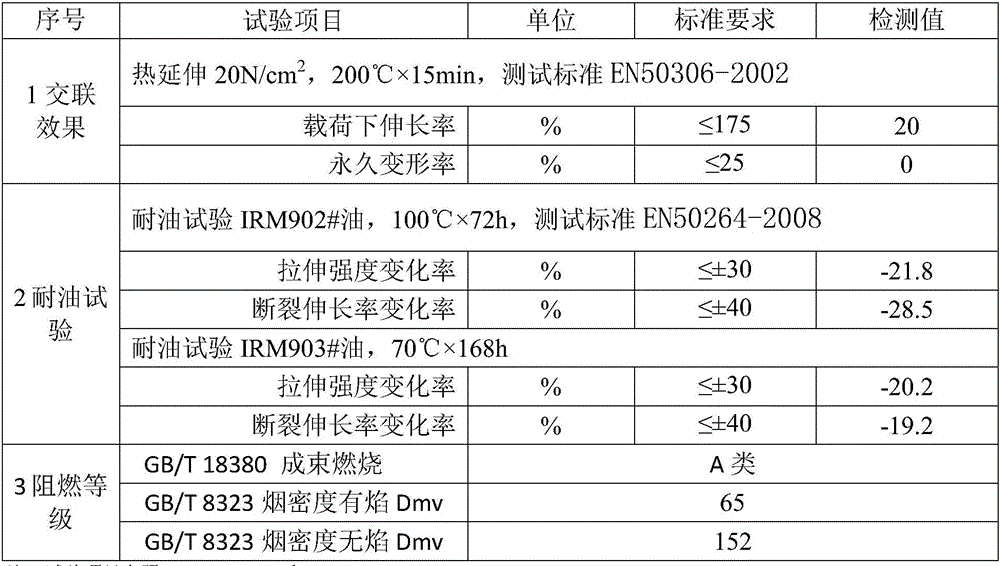

[0043] The performance index of embodiment 2 gained material is as follows:

[0044]

[0045]As can be seen from the above examples, the present invention increases the amount of EVA with high VA content in the material formulation and the synergistic effect between the various raw material components, so that the oil resistance of the material is significantly improved, and it has higher oil resistance and oil resistance. Flammability;.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com