Drippage-resisting agent and preparation method thereof as well as thermoplastic resin product containing drippage-resisting agent

A thermoplastic resin and anti-dripping agent technology, applied in the field of thermoplastic resin products, can solve the problems of surface defects, low polytetrafluoroethylene content, and low anti-drip properties of thermoplastic resin products, and achieves good anti-drip and flowability. The effect of good performance and high flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

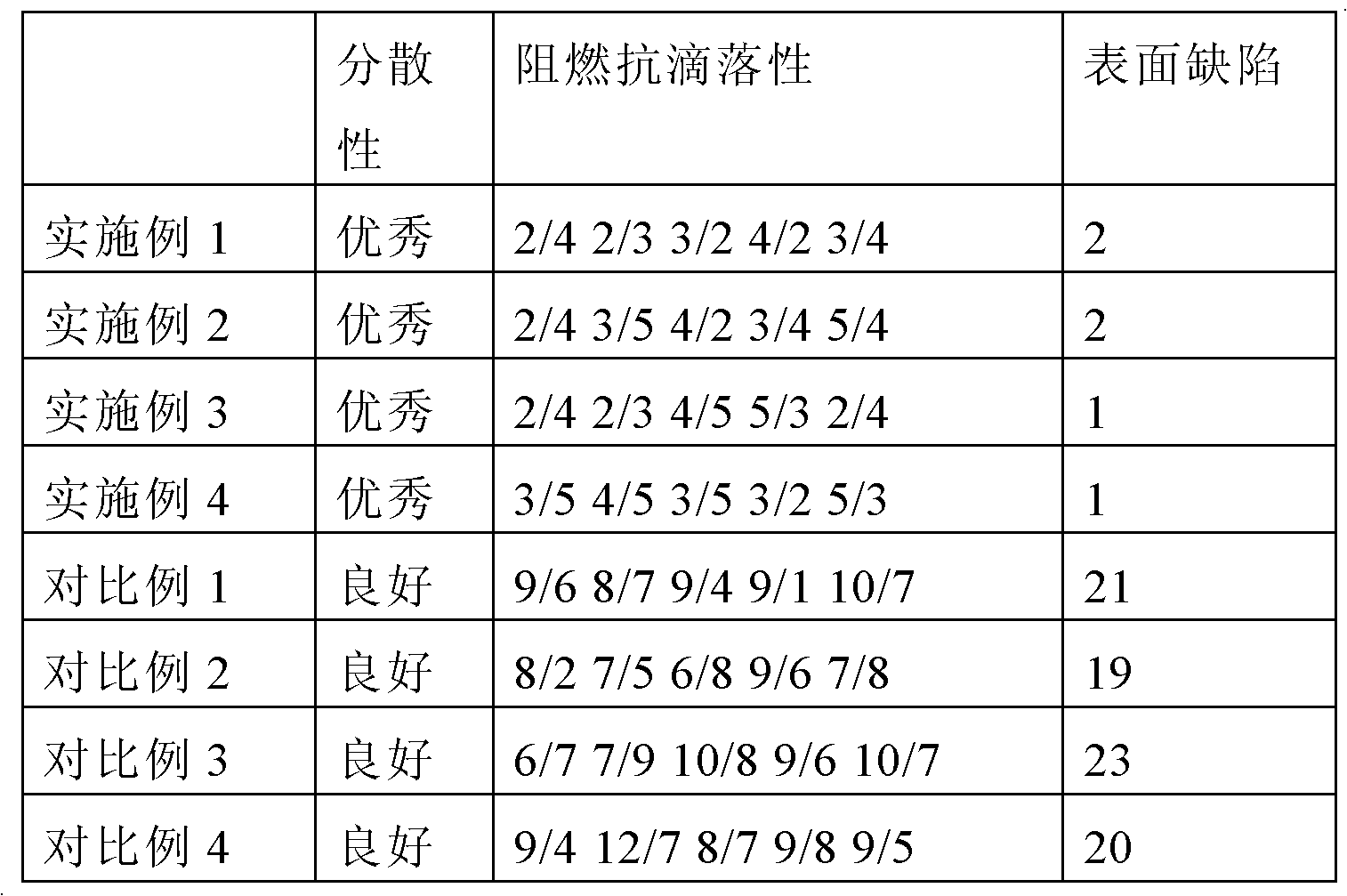

Examples

preparation example Construction

[0025] The preparation method of the above-mentioned MQ silicone resin is to first add a head sealant and a silicate monomer, a strong acid such as hydrochloric acid or sulfuric acid, deionized water, and a solvent such as toluene, xylene, methyl ethyl ketone or ethanol to the reactor. or a mixture of two or more. Then add the core emulsion solution while stirring, carry out hydrolysis and condensation, keep the hydrolysis state and stir the reaction for 1-10 hours, preferably 2-5 hours, so that the reaction is complete. Finally add toluene for extraction, the extraction process is 1 to 4 hours, preferably after 1 to 2 hours, pour the reaction solution into a separatory funnel for layering, divide the water layer, wash the oil layer to neutral, distill and dry to remove the toluene to obtain anti-dripping The agent is dried to make the water content less than 5%, preferably less than 1%, to obtain the finished anti-dripping agent.

[0026] In order to effectively control the ...

Embodiment 1

[0049] Add 7.4 grams of 1,3 divinyl-1,1,3,3,-tetramethyldisiloxane, 0.3 ml of concentrated hydrochloric acid, and 3 ml to a 250 ml three-necked flask equipped with a thermometer, a reflux device and a stirring device. The mixed solution of ionized water and 6ml ethanol was then started to stir, and then 50 grams of polytetrafluoroethylene concentrated dispersion (teflon 30J from DuPont, USA, solid content 60%) was added dropwise within 1 hour. Then quickly drop 10.4 grams of tetraethyl orthosilicate for hydrolysis and condensation. After hydrolysis for 1 hour, add 50ml of toluene for extraction. After 1 hour, pour the reaction solution into a separatory funnel for layering. After distilling and drying to remove toluene, 43.2 grams of white powdery solids are obtained as white microspheres, with an average particle diameter of 0.7mm, wherein the polytetrafluoroethylene content is 69% by weight, and the M / Q ratio of the silicone resin measured by the above method is 0.88.

Embodiment 2

[0051] The manufacturing process is the same as in Example 1, except that the silane monomer is replaced by 13.2 grams of tetraethyl orthosilicate. The reaction product was washed with water to obtain 45.2 grams of anti-dripping agent, wherein the polytetrafluoroethylene content was 66%. It is a white microsphere with an average particle diameter of 0.5mm, and the M / Q ratio of the silicone resin measured by the above-mentioned method is 0.76.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com