High-precision automatic tile fixing machine

A tiling, high-precision technology, applied in the direction of architecture, building construction, etc., can solve the problems of complicated operation, time-consuming, tile hollowing, etc., and achieve the effect of convenient and simple operation, wide adaptability, and solving hollowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

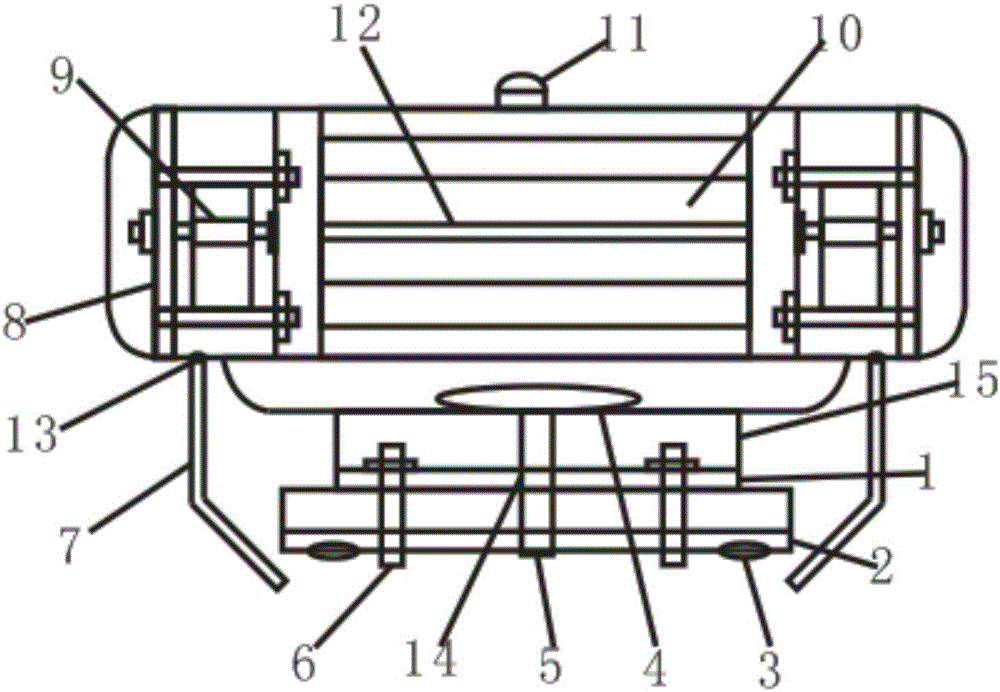

[0017] see figure 1 and figure 2 , the present invention provides a technical solution: a high-precision automatic tiling machine, including a pressure-bearing base plate 1, as a carrier for a vibrating plate 2, a vibrating motor 15 and other equipment, and a vibrating plate is fixedly installed on the lower surface of the pressure-bearing base plate 1 2. Tamp the conveyed mortar to prevent hollowing, and a vibrating motor 15 is fixedly installed on the upper surface of the pressure-bearing bottom plate 1, and as a vibration element, a smoothing turntable 3 is also fixedly installed on the bottom of the vibrating plate 2, The number of the smoothing turntables 3 is four, and the four smoothing turntables 3 are respectively fixedly installed on the four corners of the vibrating plate 2, and the mortar sent down is leveled to prevent the hollowing caused by the unevenness of the mortar. A height measuring rod 5 and a pressure rod 6 are interspersed between the pressure-bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com