Adjustable concrete lintel casting mold and usage method thereof

A technology for pouring molds and concrete, which is applied in the direction of construction, building structure, formwork/formwork/work frame, etc. It can solve the problems of non-adjustable mold size, large labor consumption, and waste of materials, so as to save costs, manpower, and operation Convenience and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

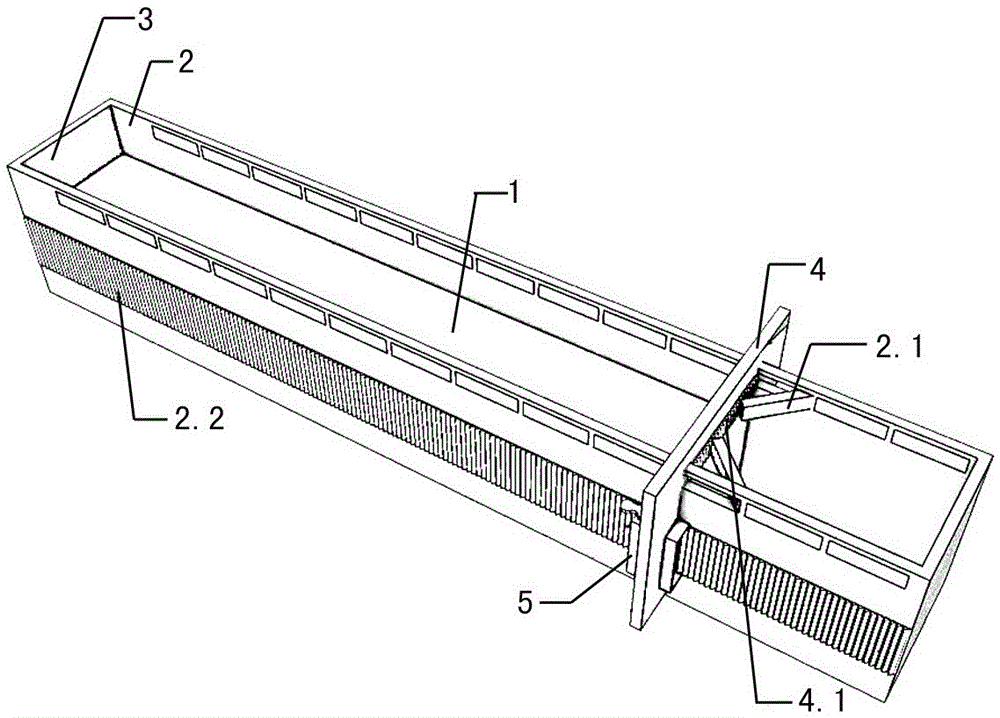

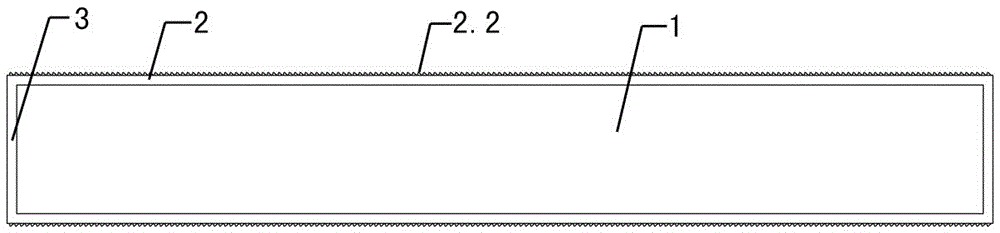

[0042] Examples see figure 1 and figure 2 Shown, a kind of adjustable concrete lintel pouring mould, is wooden mould, comprises the sliding formwork 4 that size is 340mm * 470mm * 20mm that is 340mm * 470mm * 20mm that is slidingly connected on the mold box; 1800mm×240mm×20mm bottom template 1, a pair of side templates 2 with a size of 320mm×1840mm×20mm connected to both sides of the bottom template 1, and a pair of side templates with a size of 240mm×320mm×20mm connected to both ends of the bottom template 1 A rectangular box composed of formwork 3; the sliding formwork 4 is clamped with the side formwork 2 through a clip 5.

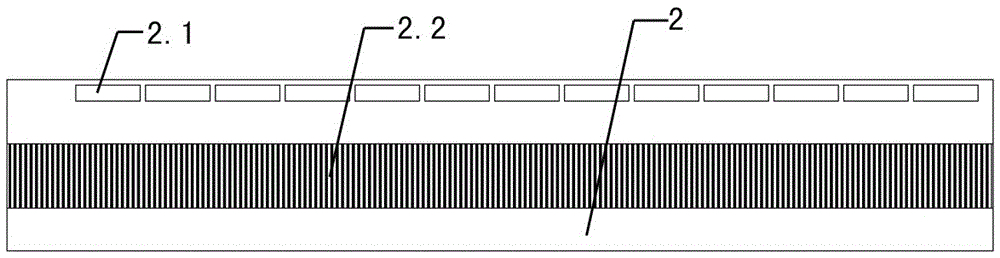

[0043] see image 3 and Figure 4 As shown, the body of the side formwork 2 is horizontally provided with a long first clamping strip 2.2 along its length direction, with a size of 1840mm×140mm, and spines are evenly distributed on the first clamping strip 2.2; The spines are dotted or striped; see figure 1 and image 3 As shown, the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com