Method for improving hole sealing effect based on drilled surrounding rock fracture structure

A fissure and hole sealing technology, which can be used in earth-moving drilling, sealing/sealing, gas discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

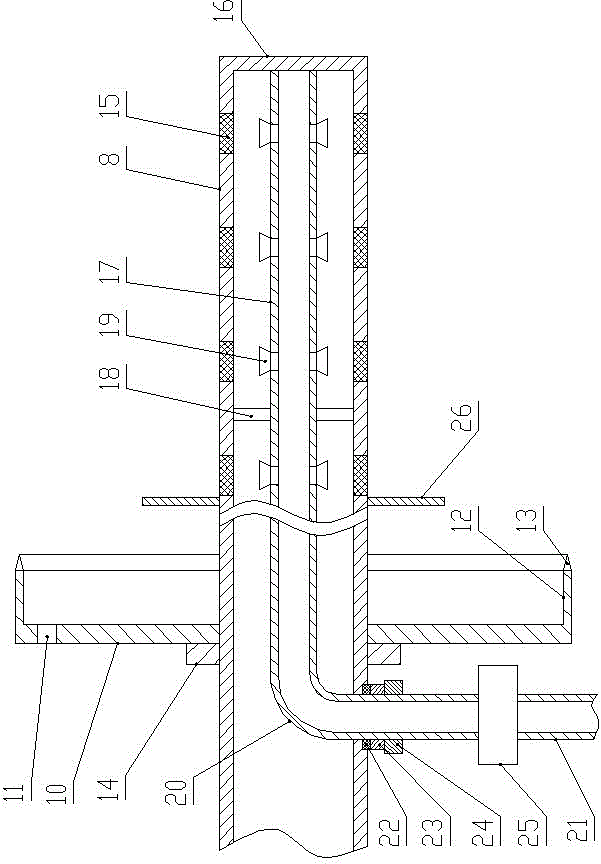

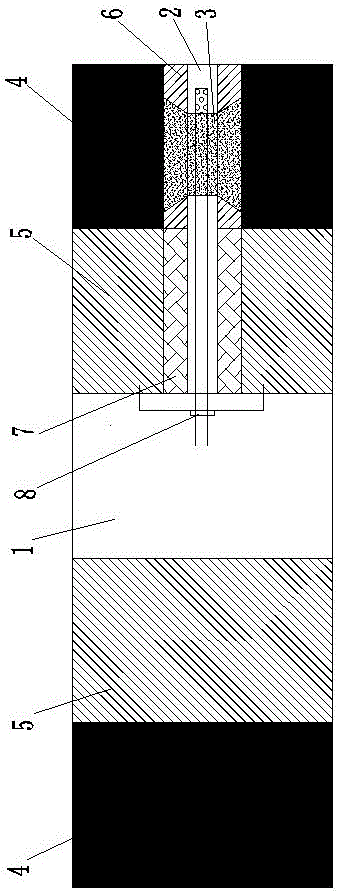

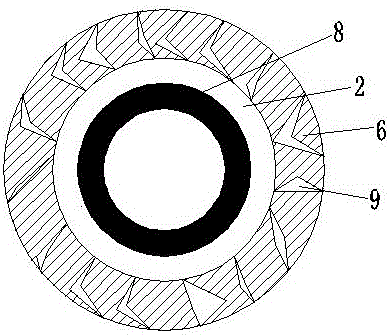

[0023] Such as Figure 1-Figure 4 As shown, the method for improving the sealing effect based on the crack structure of the drilling surrounding rock of the present invention comprises the following steps:

[0024] 1) First, confirm the U-shaped pressure-relieving coal mass area 5 affected by the roadway excavation, and obtain the annular pressure-relieving coal mass area 6 produced by the drilling from various parameters of the borehole, and then obtain the concentration of the coal mass affected by the borehole drilling. Coal body fracture area 7 that is jointly affected by the fractured zone caused by the influence of stress and the stress concentration zone caused by roadway excavation; figure 1 The winning mark 4 is the coal body that is not affected by roadway excavation and drilling;

[0025] 3) According to the geological characteristics of the coal field, analyze the development of primary fractures in the coal body structure, consider the stress of the surrounding r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com