Cutting part of stepless speed changing coal cutter based on hydraulic closed transmission system

A technology for the cutting part and transmission system of a coal shearer, which is applied to cutting machinery, driving devices, earthwork drilling and mining, etc. It can solve the problems that cannot be optimized in real time, and the drum cannot be continuously variable, so as to achieve strong practicability and convenient operation quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

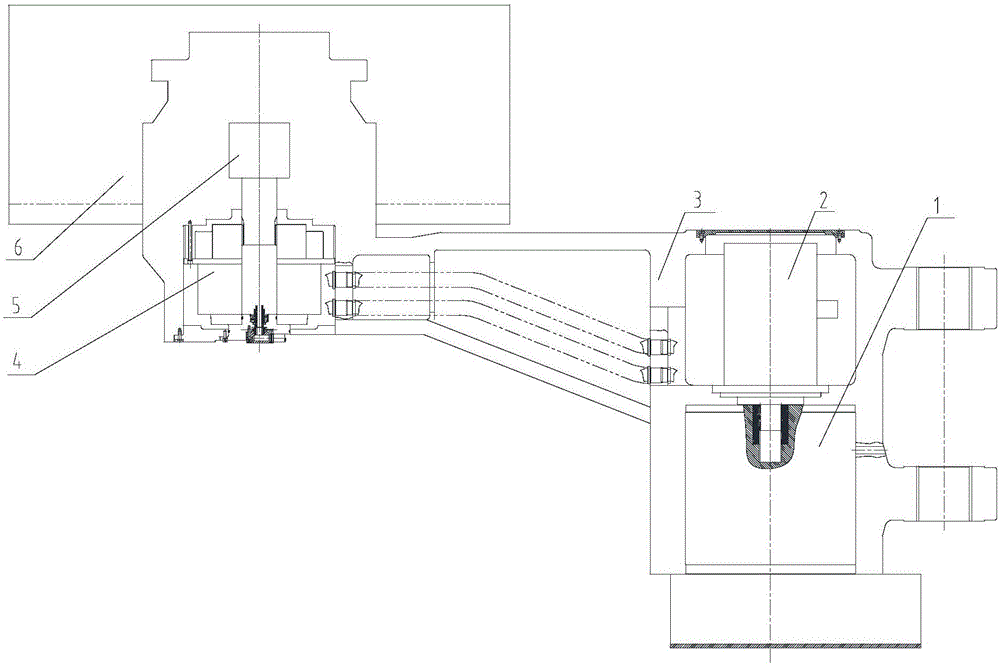

[0019] exist figure 1 Among them, the motor 1, the pump 2 and the motor 4 are respectively fixedly installed in the casing of the cutting part (rocker arm). The motor 1 is connected to the pump 2 and rotates to drive the pump 2 to absorb and discharge oil. The motor 1 is connected to the pump 2 directly or through a transfer case. The pump 2 is connected with the motor 4 through a hydraulic pipeline 7 to realize power transmission. The motor 4 transmits the output power to the connecting shaft 5, and the connecting shaft is connected with the drum 6 to realize the final power output.

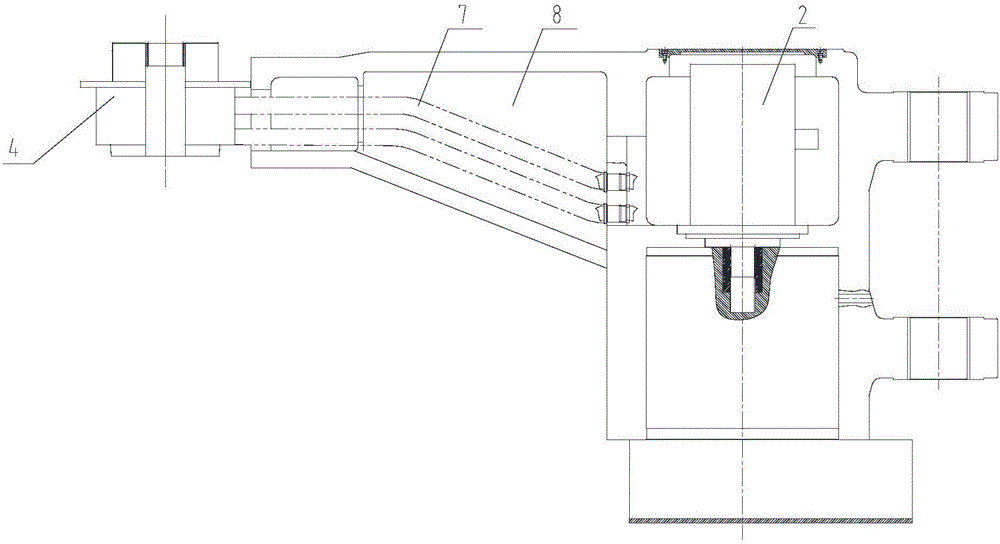

[0020] exist figure 2 In the hydraulic transmission system shown, the pump 2 is connected to the motor 4 through the hydraulic pipeline 7, and the hydraulic pipeline is provided with supplementary oil to form a closed hydraulic transmission system. The oil tank 8 is arranged between the motor and the pump, and the interior is provided with oil , used to realize oil replenishment and oil heat ...

Embodiment 2

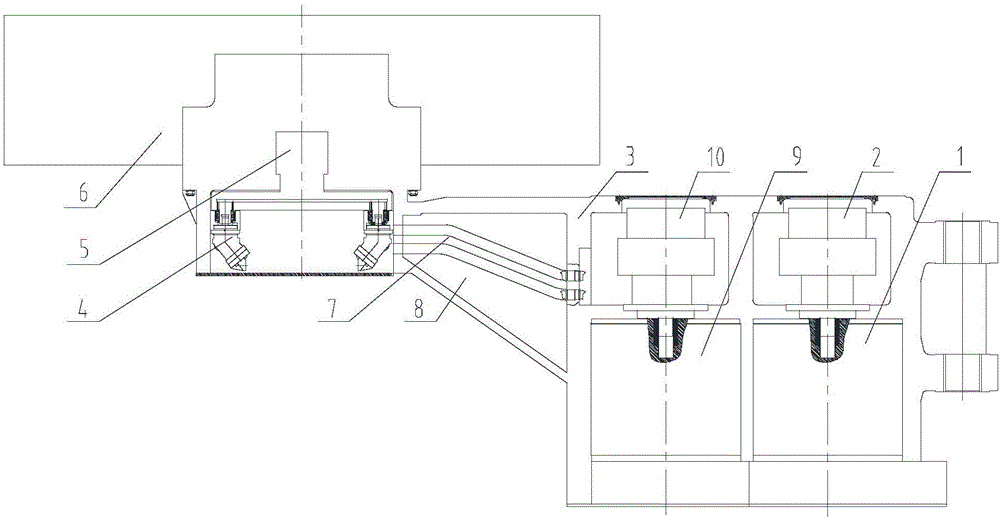

[0022] image 3 It is a cutting part (rocker arm) with two sets of motors and pumps. The first motor 1 is connected to the first pump 2, and the second motor 9 is connected to the second pump 10. After the two sets of pumps merge, they are connected to the motor 4 through the hydraulic pipeline 7. The hydraulic pipeline is equipped with supplementary oil, so that the motor, hydraulic pipeline and pump form a closed hydraulic transmission system to form a closed hydraulic transmission system. The motor drives the pump, and the pump absorbs and discharges oil to transfer power to the motor. The combination 5 of the gear transmission and the planetary mechanism is connected to the drum 6, and finally drives the drum 6 to rotate.

[0023] The oil tank 8 is arranged between the motor and the pump, and oil is arranged inside to realize oil replenishment and oil heat exchange. The speed adjustment of the motor 4 is realized through the flow adjustment of the variable displacement pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com