Adaptive dynamic weight system and work process of automatic checkweigher

A self-adaptive system and automatic detection technology, applied in the detailed information of weighing equipment, weighing, special scales, etc., can solve the problems of high professional technical requirements of operators, inaccurate detection accuracy, complicated device operation, etc., and achieve simplification. Operation and skill requirements, broad application prospects, and the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

[0017] A dynamic weight self-adaptive system of an automatic check weighing scale includes a dynamic weighing unit, a photoelectric sensor, a weighing sensor, a microprocessor circuit and a man-machine interface. The human-machine interface adopts a touch display screen, and the microprocessor circuit adopts a single-chip microcomputer.

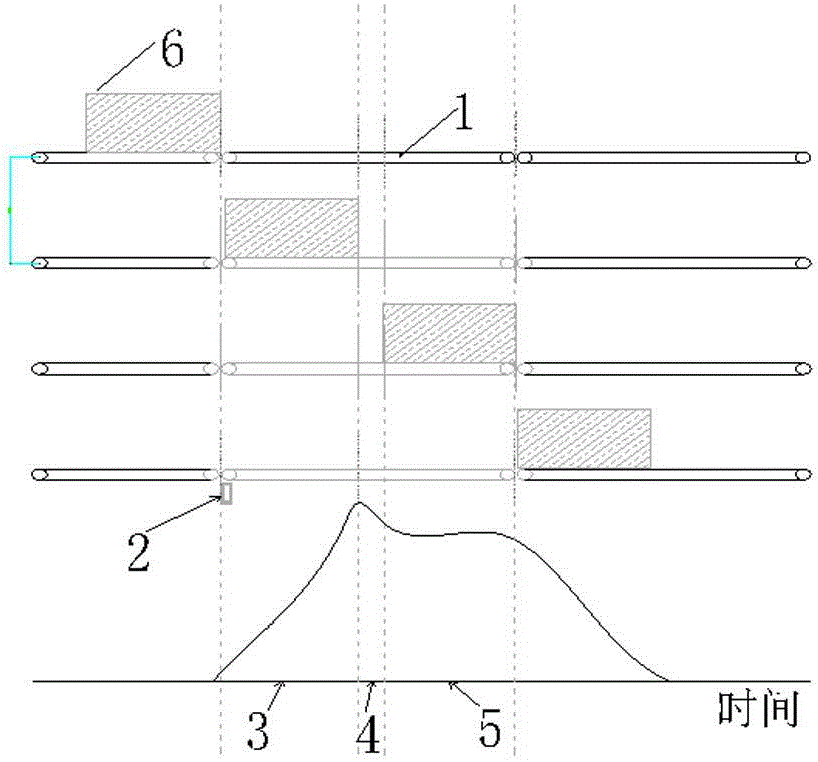

[0018] The working process of the dynamic weight adaptive system of the automatic checkweigher, the specific steps are as follows:

[0019] Step 1, preset: preset the belt length, product length and detection rate per minute of the dynamic weighing unit on the man-machine interface;

[0020] Step 2, data punching and calculation: put the product into the weighing detection, the photoelectric sensor detects that the product enters the dynamic weighing unit, and the microprocessor circuit calculates the conveyor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com