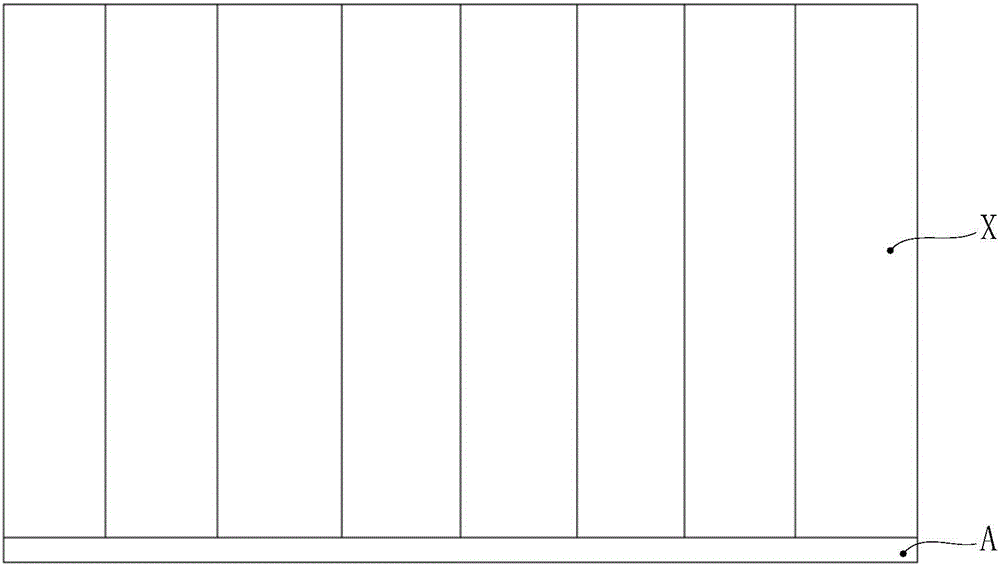

Magnetic induced light-dimming material, local backlight adjustment membrane, backlight module and display equipment

A backlight module and magnetic material technology, applied in optics, optical components, nonlinear optics, etc., can solve problems such as inability to perform accurate local backlight adjustment, inability to realize local backlight adjustment, and insufficient fineness of backlight partitions. Adjust the backlight in rows or columns, which is beneficial to the development and improves the display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

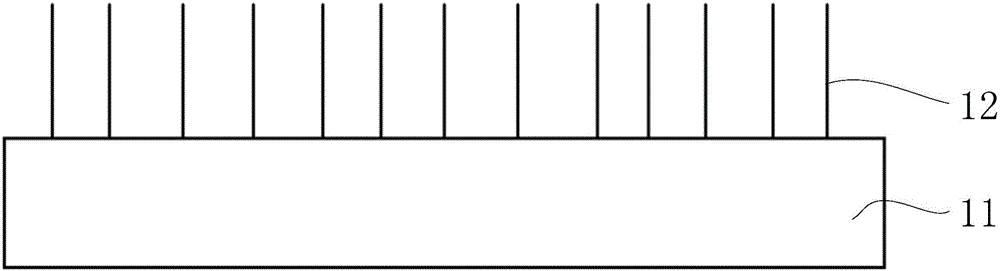

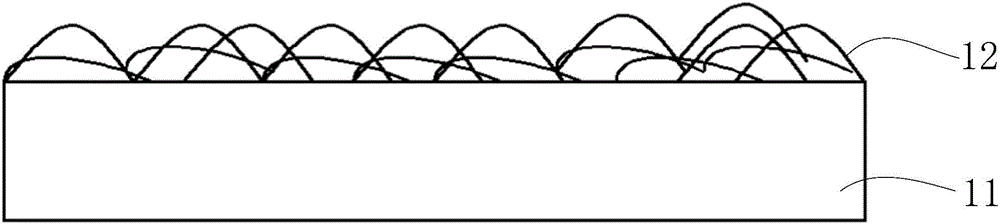

[0099] This embodiment provides a magnetic light-adjusting material using Dow Corning's SYLGARD184 two-component silicone rubber as the material of the transparent base and the elastic matrix of elastic bristles, and a local backlight adjustment film based on the magnetic light-adjusting material.

[0100] In the magnetic dimming material provided in this embodiment, the elastic bristles in the bristle array are cylinders with a diameter of 400 μm and a length of 1 mm, the distance between the elastic bristles is 200 μm, and the opaque magnetic material is nickel.

[0101] In this embodiment, vacuum injection molding is adopted to prepare the above-mentioned magneto-sensitive dimming material, and the specific steps include:

[0102] Firstly, it is determined to process the polytetrafluoroethylene cathode mold according to the parameters such as the size and spacing of the above-mentioned elastic bristles, and the mold surface is coated with a release agent; then the basic comp...

Embodiment 2

[0106] This embodiment provides a magnetic light-adjusting material using Dow Corning's SYLGARD184 two-component silicone rubber as the material of the transparent base and the elastic matrix of elastic bristles, and a local backlight adjustment film based on the magnetic light-adjusting material.

[0107] In the magnetic dimming material provided in this embodiment, the elastic bristles in the bristle array are cylinders with a diameter of 0.5 μm and a length of 40 μm, the distance between the elastic bristles is 10 μm, and the opaque magnetic material is nickel.

[0108] In this embodiment, vacuum injection molding is adopted to prepare the above-mentioned magneto-sensitive dimming material, and the specific steps include:

[0109] First of all, it is determined to process the polytetrafluoroethylene cathode mold according to the parameters such as the size and spacing of the above-mentioned elastic bristles, and the mold surface is coated with a release agent; then the basic...

Embodiment 3

[0113] This embodiment provides a magnetic light-adjusting material using Dow Corning's SYLGARD184 two-component silicone rubber as the material of the transparent base and the elastic matrix of elastic bristles, and a local backlight adjustment film based on the magnetic light-adjusting material.

[0114] In the magnetic dimming material provided in this embodiment, the elastic bristles in the bristle array are cylinders with a diameter of 1 mm and a length of 10 mm, the distance between the elastic bristles is 500 μm, and the opaque magnetic material is trioxide with a particle size of 10 μm. Iron (Fe 3 o 4 ).

[0115] In this embodiment, vacuum injection molding is adopted to prepare the above-mentioned magneto-sensitive dimming material, and the specific steps include:

[0116] First of all, it is determined to process the polytetrafluoroethylene cathode mold according to the parameters such as the size and spacing of the above-mentioned elastic bristles, and the mold su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com