Low-temperature peanut pressing control method and system

A control method and control system technology, which is applied in the field of peanut low-temperature pressing control method and system, can solve problems such as inability to operate continuously, affect pressing work, and decrease material friction, and achieve the effect of facilitating continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

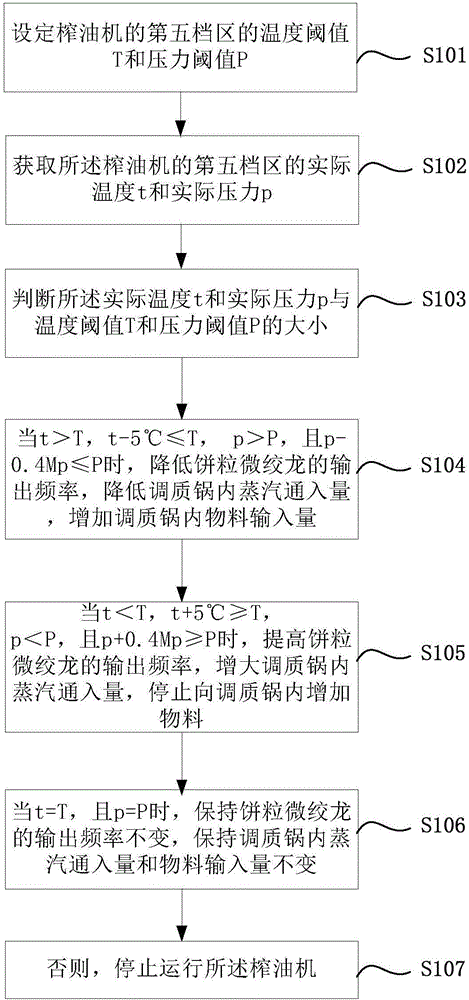

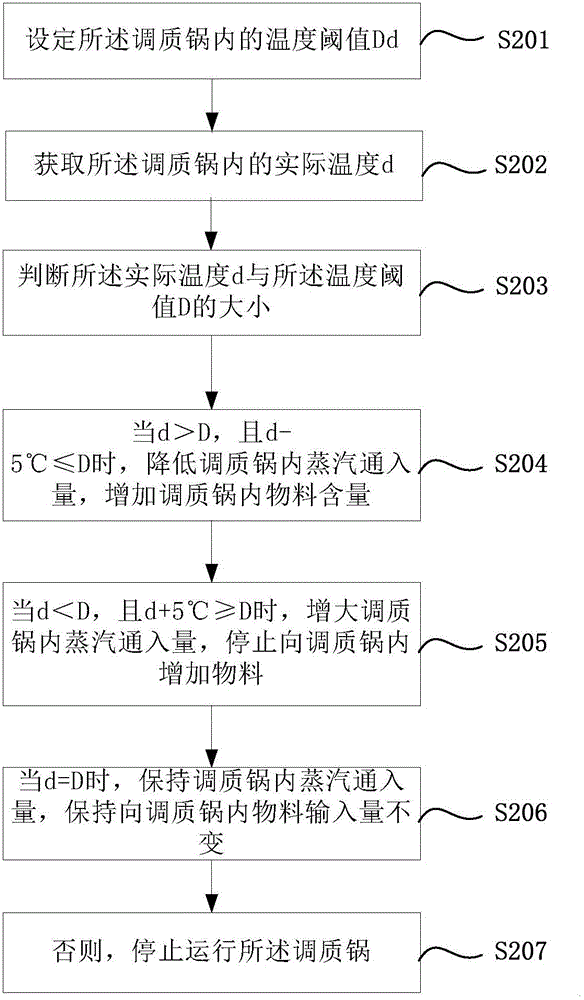

Embodiment 1

[0086] After the oil press is in normal operation, the temperature and pressure sensor on the machine chamber, such as the temperature and pressure sensor pt02a-10-6p, measures the temperature in the machine chamber as 76°C and the pressure value as 2.8Mpa; the temperature controller on the tempering pot, For example, the temperature measured by the temperature controller CB401 is 62°C. At this time, the oil press normally feeds half grains after conditioning, and the output frequency of the micro-screwed dragon inverter that adds cake grains is 26Hz; after half an hour of normal operation of the oil press, The temperature and pressure sensor measured the temperature inside the machine chamber as 79°C, and the pressure value was 3.2Mpa. The temperature controller on the tempering pot measured the temperature as 64°C. The frequency becomes 23Hz, the opening degree of the steam regulating valve JHZAZ2 becomes smaller, the amount of steam input in the tempering pot becomes smaller...

Embodiment 2

[0088] After the oil press is in normal operation, the temperature and pressure sensor on the machine chamber, such as the temperature and pressure sensor pt02a-10-6p, measures the temperature in the machine chamber as 71°C and the pressure value as 2.6Mpa; the temperature controller CB401 on the tempering pot The measured temperature is 58°C. At this time, the oil press normally feeds half grains after conditioning, and the output frequency of the micro-screw inverter that adds cake grains is 25Hz; after half an hour of normal operation of the oil press, the temperature and pressure sensor measures The temperature inside the machine chamber is 69°C, the pressure value is 2.5Mpa, and the temperature measured by the temperature controller on the tempering pot is 55°C. The valve opening degree of the regulating valve JHZAZ2 becomes larger, and the amount of steam input in the tempering pot becomes larger, and the flow rate is 215 kg / hour. When the material level switch on the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com