Intelligent material dispatching system based on large data in sugar factory

An intelligent scheduling and big data technology, applied in data processing applications, instruments, resources, etc., can solve the problems of unfavorable management and operation, timely decision-making, insufficient depth of analysis of on-site production conditions by summarizing data, and lack of talents, so as to adapt to on-site control needs, avoiding business risks, and revealing the effects of strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

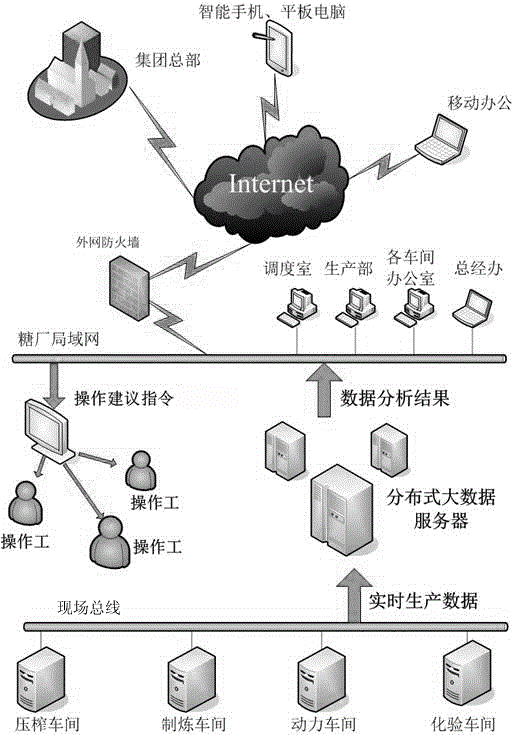

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, the system architecture of the material intelligent scheduling system based on big data adopts a three-layer architecture system of lower computer→server→client, and uses fieldbus technology, local area network and wide area network communication technology to form a real-time communication network to form a distributed monitoring system. The lower computer is the control layer, the server and the client are the information management layer, the field bus technology adopts MODBUS field bus, the local area network and the wide area network adopt the combination of wired network and wireless network, the control layer is separated from the information management layer, and the autonomy of the field equipment is improved. In addition, its basic process control, alarm and calculation functions are completely distributed and completed on si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com