Busbar voltage control method for brushless direct current motor-driven frequency converter

A busbar voltage control, brushed DC motor technology, applied in electrical components, output power conversion devices, etc., can solve problems such as unfavorable inverter heat dissipation, reduced system energy consumption, increased heat loss of power devices, etc., to ensure normal operation. and heat dissipation, reliability assurance, and the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

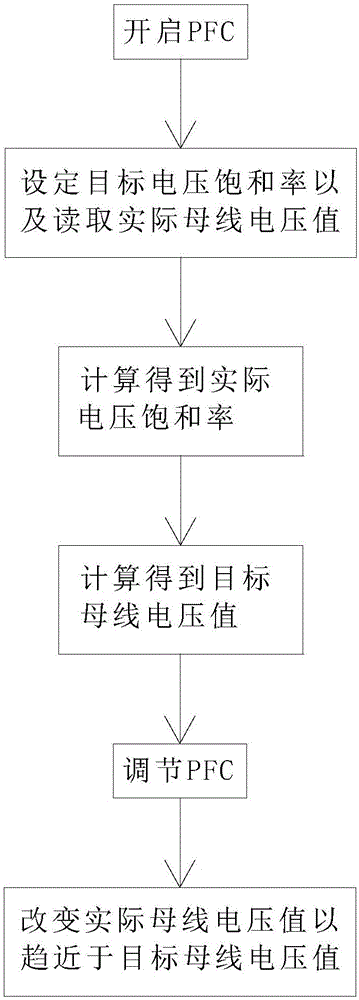

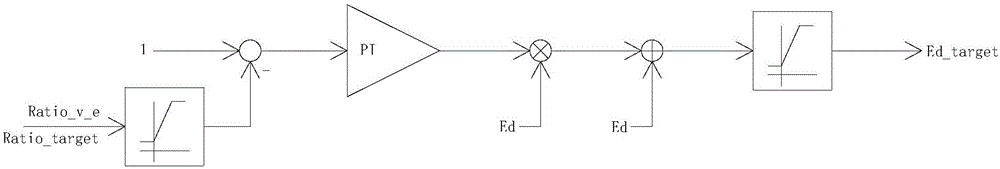

[0024] Such as figure 1 , figure 2 As shown, the present invention is a bus voltage control method for brushless DC motor drive frequency converter, comprising the following steps,

[0025] (1) Turn on PFC;

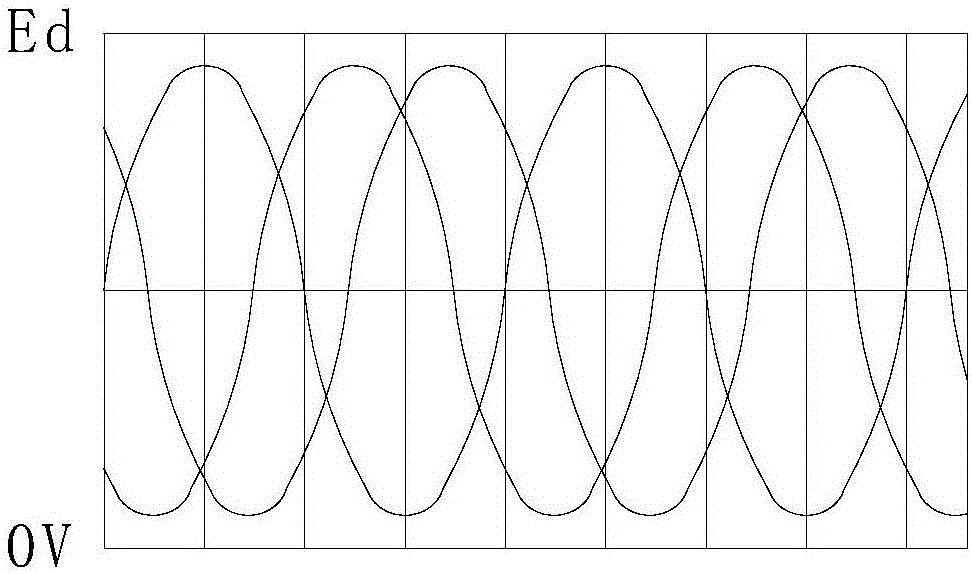

[0026] (2), setting the target voltage saturation rate Ratio_target and reading the actual bus voltage value Ed, in the present embodiment, the target voltage saturation rate is generally set to about 90%; the relationship between the bus voltage and the motor drive phase voltage is as attached image 3 shown.

[0027] (3) Calculate the actual voltage saturation rate Ratio_v_e;

[0028] (4), calculate the target bus voltage value Ed_target;

[0029] (5), adjust PFC;

[0030] (6) Change the actual bus voltage value Ed to approach the target bus voltage value Ed_target; that is, change the actual bus voltage value Ed so that the actua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com