Water cooling type efficient wire cooling device

A cooling device, water-cooled technology, applied in the direction of workpiece cooling device, workpiece surface treatment equipment, metal rolling, etc., can solve the problems of different shrinkage speed, poor fluidity of cooling water, affecting the quality of wire rods, etc., to achieve good cooling effect, Avoid waste, the effect of high wire quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

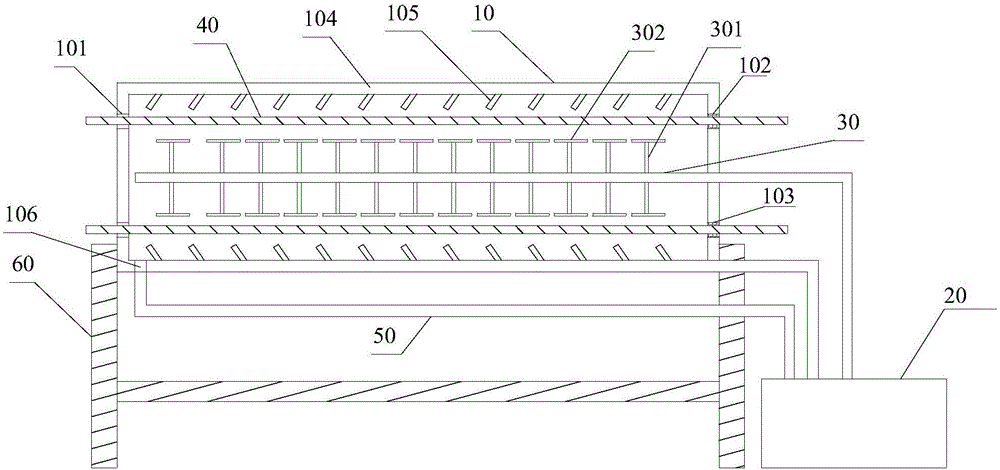

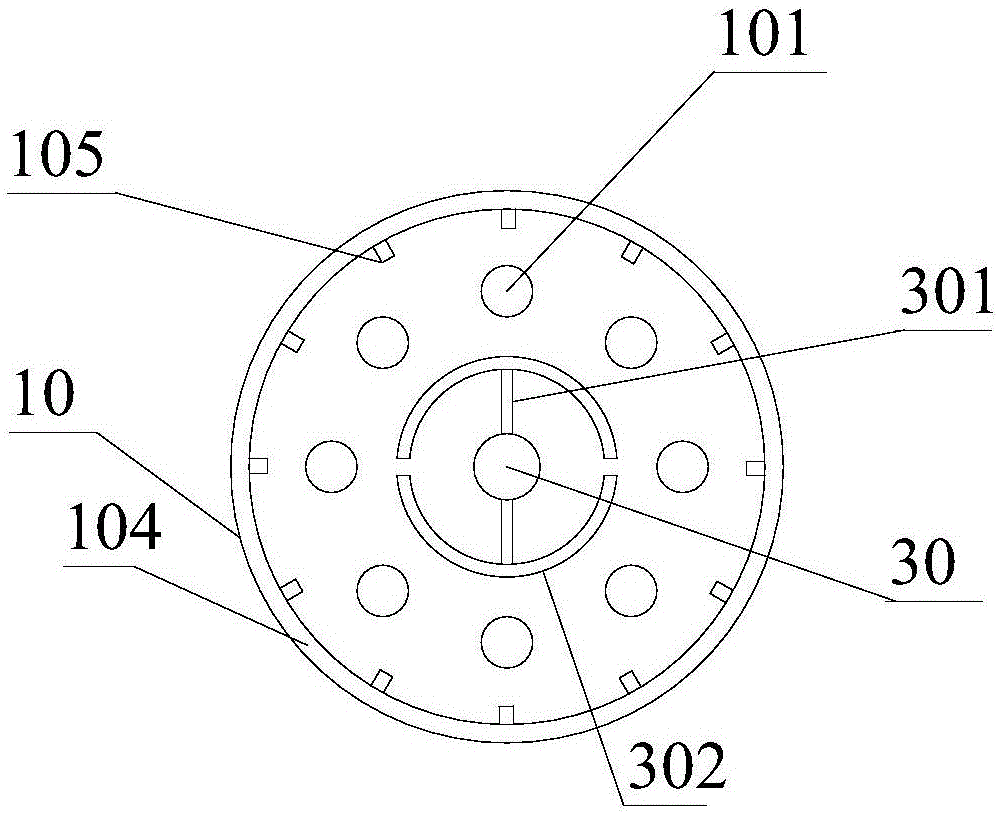

[0017] refer to figure 1 , figure 2 , the present invention proposes a water-cooled high-efficiency cooling device for wire rods, including a frame 60, a box body 10, a water tank 20, and a cooling water circulation pipe 50, wherein:

[0018] The box body 10 is installed on the frame 60, and a main water pipe 30 is provided on the inner axis of the box body 10. The length of the main water pipe 30 is adapted to the length of the box body 10. One end of the main water pipe 30 is sealed, and the other end is connected to the The water tank 20 outside 10 is connected, and the main water pipe 30 is located in the box body 10 and is provided with two rows of branch pipes 301 symmetrically. One end of the box body 10 is provided with a wire inlet 101, and the other end is provided with a wire outlet 102 in one-to-one correspondence with the wire inlet 101. The numbers of the wire inlet 101 and the wire outlet 102 are 8 respectively, and the wire inlet 101, The wire outlet holes 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com