Full-closed cushion packaging structure of cabinet air conditioner

A buffer packaging, fully enclosed technology, used in packaging, packaging food, machine containers, etc., can solve the problems of dust entry, damage to parts, easy bumping, extrusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

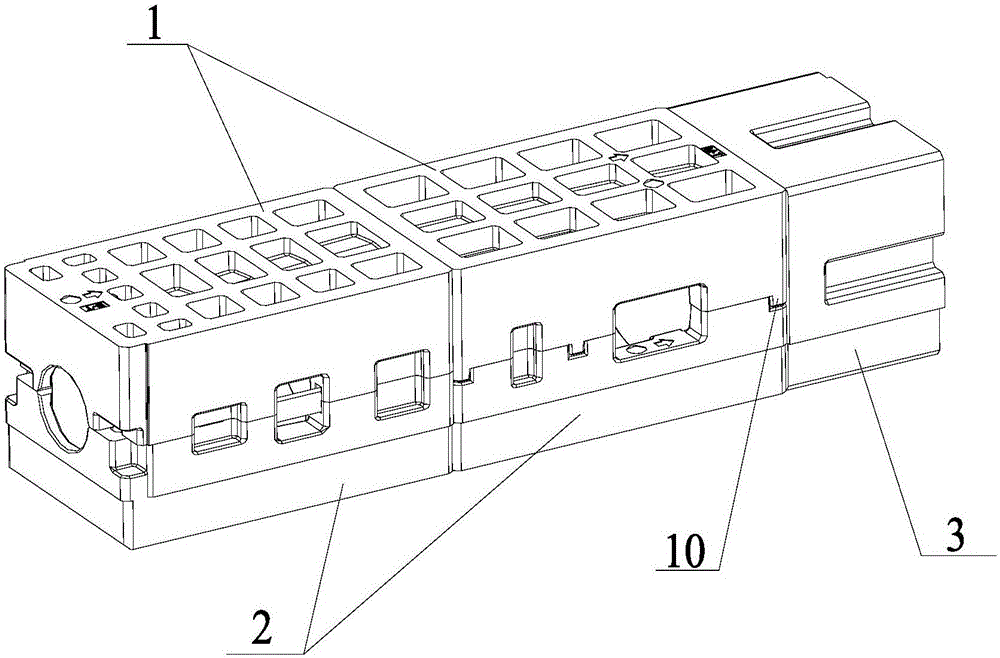

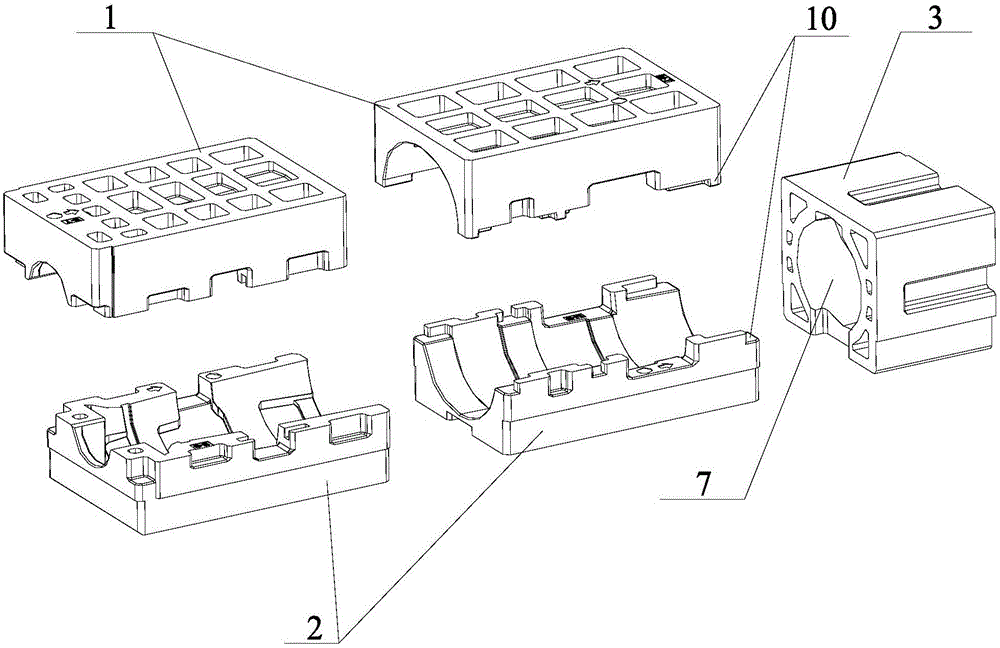

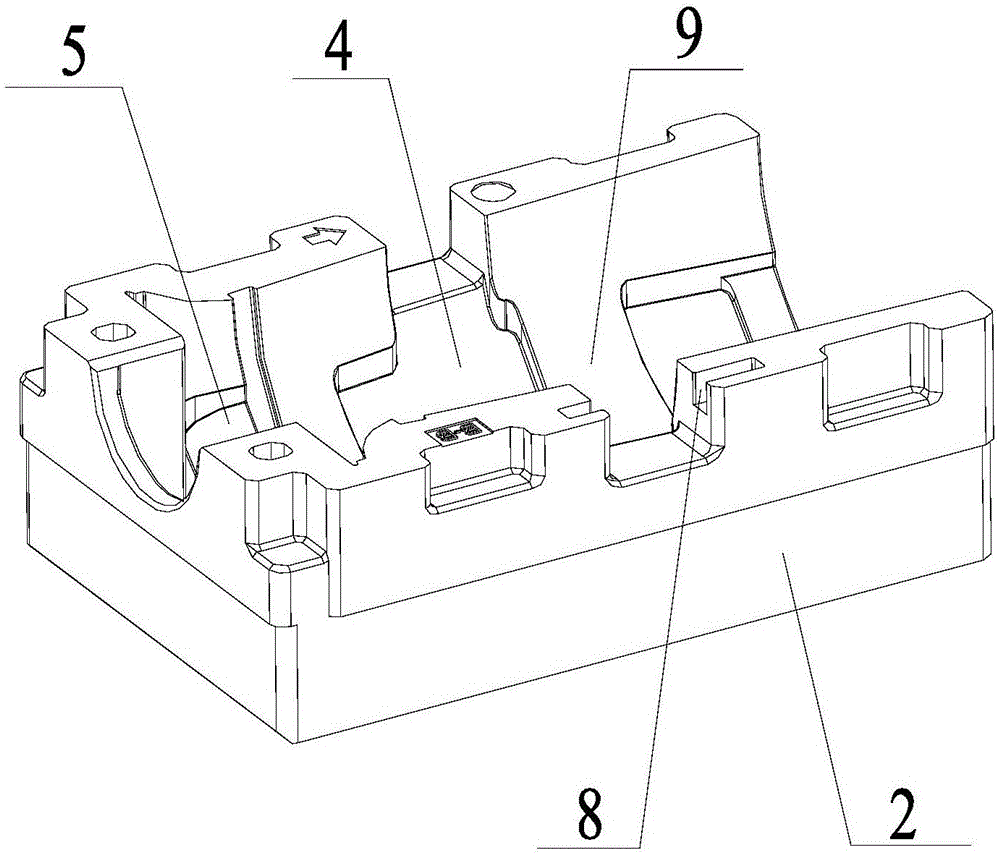

[0029] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

[0030] Such as Figure 1-6 As shown, a fully enclosed buffer packaging structure of a cabinet air conditioner includes an upper packaging shell 1 and a lower packaging shell 2 oppositely arranged. The middle portions of the upper packaging shell 1 and the lower packaging shell 2 are respectively provided with symmetrical body storage The slot 4, the accessory storage slot 5, the upper packaging shell 1 and the lower packaging shell 2 are provided with mutually matched locking components 6 on the opposite sides.

[0031] The packaging method of the packaging structure is that the upper packaging shell 1 and the lower packaging shell 2 are butted, the body storage slot 4 and the accessory storage slot 5 on the opposite sides of the two form a cavity, and the main body of the cabinet air conditioner to be packaged is placed in the bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com