Wood-plastic plate collecting and placing equipment

A wood-plastic board and equipment technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as difficulty in picking and placing, and achieve the effect of life safety guarantee and avoiding high-intensity work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

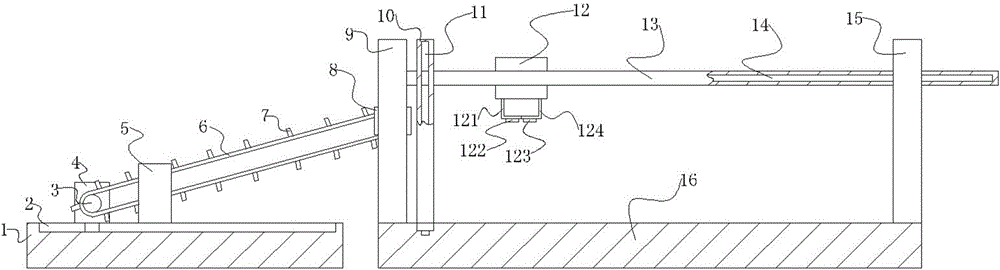

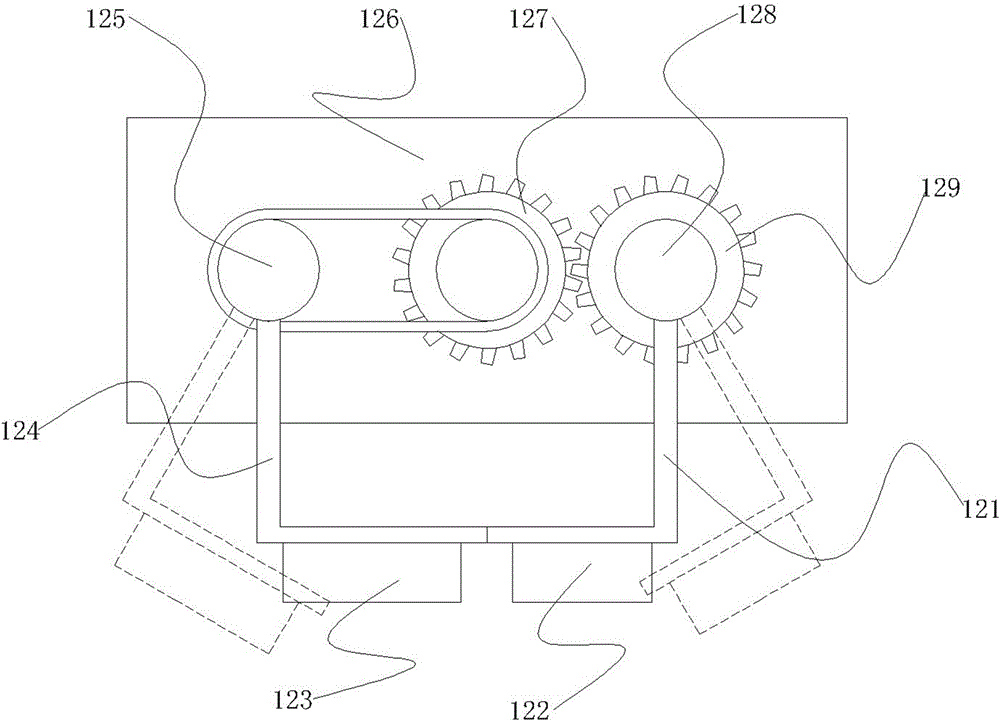

[0019] The reference signs in the drawings of the description include: bottom plate 1, slide rail 2, output shaft 3, first bearing seat 4, positioning plate 5, conveyor belt 6, pallet 7, second bearing seat 8, first pillar 9, Adjusting column 10, guide groove 11, pick-and-place device 12, first lifting block 121, first resisting block 122, second resisting block 123, second lifting block 124, first connecting shaft 125, placement plate 126 , the first gear 127 , the second connecting shaft 128 , the second gear 129 , the horizontal bar 13 , the guide groove 14 , and the fourth pillar 15 .

[0020] The embodiment is basically as attached Figure 1~2 Shown: a wood-plastic board pick-and-place equipment, including a transmission device, a placement frame and a pick-and-place device 12; the transmission device includes a bottom plate 1, a first bearing seat 4 and a second be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com