A kind of preparation method of aescin b

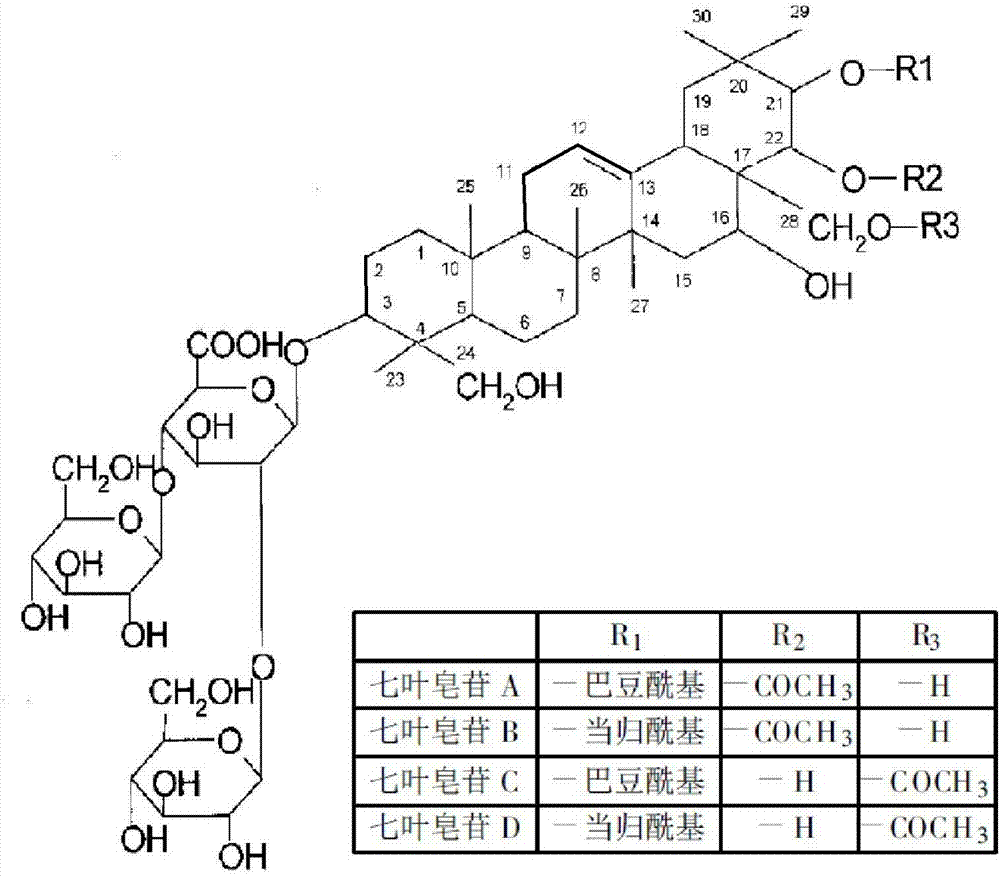

A technique of aescin and crystallization, which is applied in the field of preparation of aescin B, can solve the problems of strong stimulating effect, time-consuming process route, large amount of solvent used, etc., and achieves excellent anti-inflammatory, low muscle and mucosal irritation, Addressing the effects of uniformity and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Extraction: take 1 kg of saffron seed powder and extract twice, each time with 10 L of ethanol aqueous solution with a mass concentration of 70%, stir and extract at 45°C for 2 hours, filter, combine the filtrates filtered twice, and rotate and recover under reduced pressure solvent and concentrated to 2L.

[0024] 2) Extraction: adjust the pH of the concentrated solution obtained in step 1) to 2 with 1 mol / L hydrochloric acid, extract 3 times with 2 L of water-saturated n-butanol, combine the organic layers and concentrate to 400 mL;

[0025] 3) The first crystallization: Add the concentrated solution obtained in step 2) into a mixed solvent of 960mL acetone and 240mL methyl tert-butyl ether, heat to reflux under stirring, then cool to 20°C to precipitate a white precipitate, filter, 45°C Dried to obtain 49g of white crystals;

[0026] 4) The second crystallization: Dissolve 49g of crystals obtained in step 3) in 200mL of hot water at 100°C, stir for 20min, then co...

Embodiment 2

[0034] 1) Extraction: take 1 kg of saffron powder and reflux extract three times, each time with 6L of 30% ethanol aqueous solution, filter, combine the filtrates, spin to recover the solvent under reduced pressure and concentrate to 2L.

[0035] 2) Extraction: adjust the pH of the concentrated solution obtained in step 1) to 3 with 3 mol / L hydrochloric acid, extract 3 times with n-butanol saturated with water, combine the organic layers and concentrate to 200 mL;

[0036] 3) The first crystallization: Add the concentrated solution obtained in step 2) into a mixed solvent of 300mL acetone and 100mL methyl tert-butyl ether, heat to reflux under stirring, then cool until a white precipitate precipitates, filter and dry to obtain a white crystal 38g;

[0037] 4) Second crystallization: Dissolve 38g of aescin crystals obtained in step 3) in 100ml of hot water at 80°C, stir for 60min, then cool the solution to precipitate a white solid, filter it with suction, and dry the solid to ...

Embodiment 3

[0041] 1) Extraction: take 1 kg of the saffron seed powder and reflux for extraction twice, each time with 15 L of 50% ethanol aqueous solution, filter, combine the filtrates, spin to recover the solvent under reduced pressure and concentrate to 3 L.

[0042] 2) Extraction: adjust the pH of the concentrated solution obtained in step 1) to 3 with 0.5 mol / L hydrochloric acid, extract 5 times with n-butanol saturated with water, combine the organic layers and concentrate to 300 mL;

[0043] 3) The first crystallization: Add the concentrated solution obtained in step 2) into a mixed solvent of 1200mL acetone and 150mL methyl tert-butyl ether, heat to reflux under stirring, then cool until a white precipitate precipitates, filter and dry to obtain a white crystal 43g;

[0044] 4) Second crystallization: Dissolve 43g of aescin crystals obtained in step 3) in 215mL of boiling water, stir for 30min, then cool the solution to precipitate a white solid, centrifuge, and dry the solid to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap