Intensive thermal insulation device and method for small-diameter pipelines

A thermal insulation device and small-diameter technology, applied in pipeline protection, thermal insulation, pipeline support and other directions, can solve the problems affecting the appearance and process quality of the unit. Installation and construction lack of attention and overall planning, etc., to achieve the effect of improving the overall appearance process, improving the thermal insulation compactness and quality process, and improving the protection ability of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

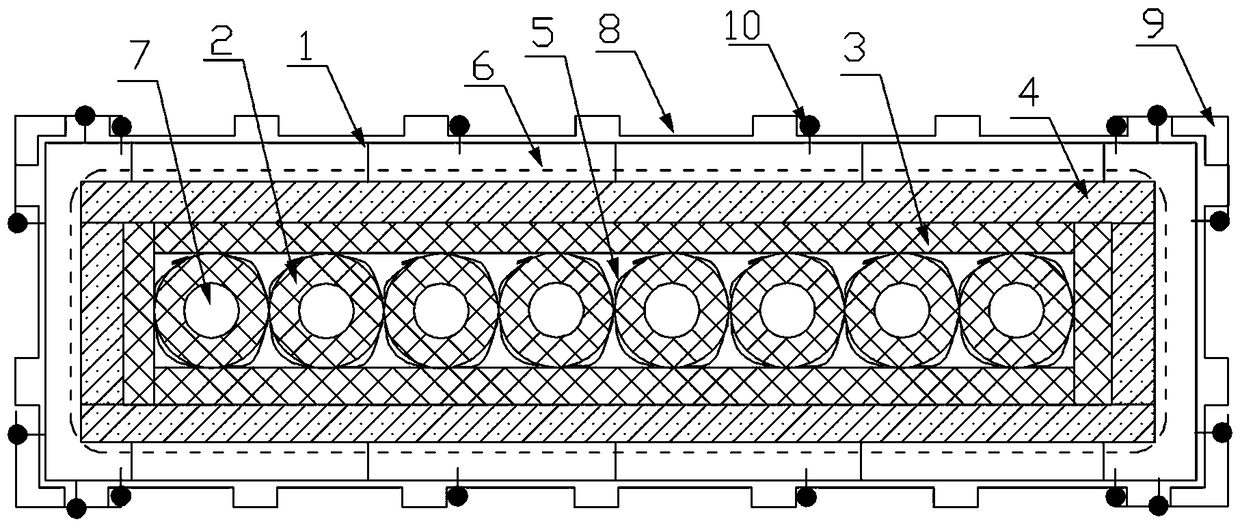

[0026] Embodiment: An intensive thermal insulation device for small-diameter pipelines, including a thermal insulation layer and an outer sheath frame support 1, the thermal insulation layer includes a first aluminum silicate fiber blanket 2 and a composite thermal insulation structure, and the first aluminum silicate fiber blanket 2 is wrapped On a single pipeline 7 to be insulated, the first aluminum silicate fiber blanket 2 is bundled with galvanized iron wire 5, and the composite thermal insulation structure is wrapped on the row of pipelines that have been wrapped with the first aluminum silicate fiber blanket 2 to be insulated as a whole. The outside of the structure is bound with barbed wire 6, and the outer layer of the barbed wire 6 is provided with an outer sheath frame support 1, and the outer sheath frame support 1 is provided with a corrugated plate 8 and a corner plate 9, and a corrugated plate 8 and a corner plate 9 Fix with self-tapping screws 10.

[0027] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com