Diaphragm coating device having online thickness measuring function

A technology for coating devices and diaphragms, which is applied in the direction of measuring devices, optical devices, battery pack components, etc., can solve the problems of not being able to improve the diaphragm, reduce the production efficiency of the enterprise, and increase the production cost, so as to improve the flatness and reduce the Scrap rate and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

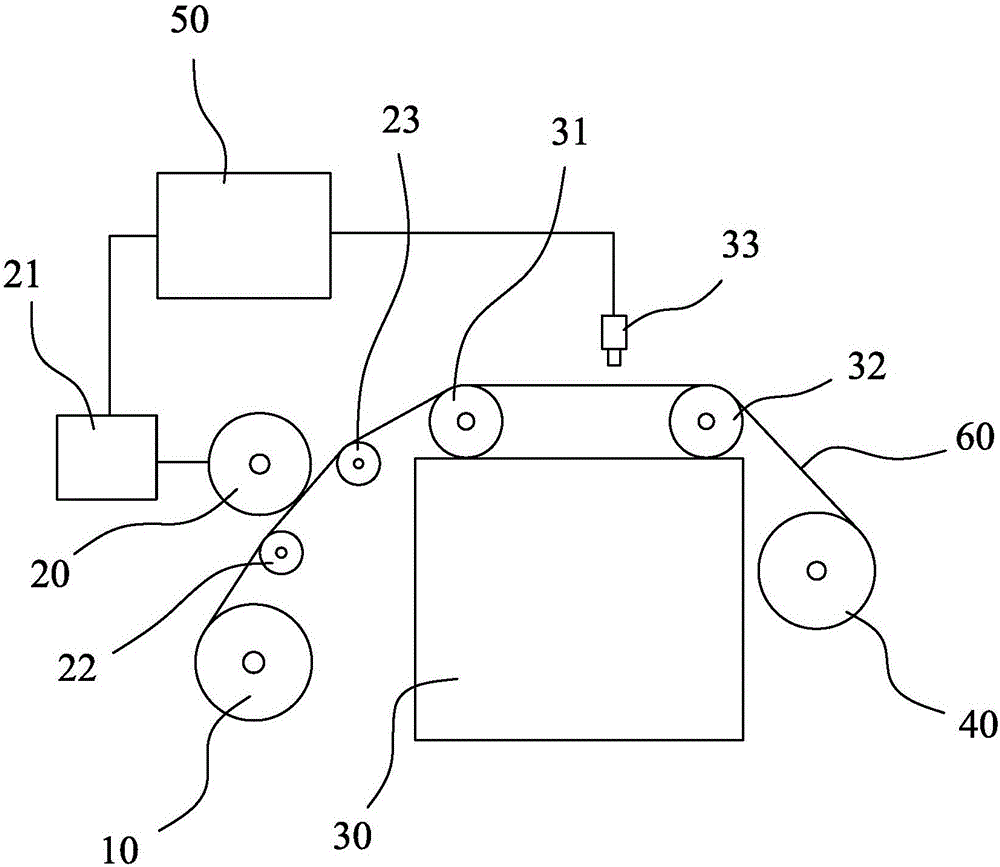

[0020] like figure 1 As shown, a diaphragm coating device with online thickness measurement function includes an unwinding roller 10, a winding roller 40, a film coating mechanism, a thickness detection mechanism and a control panel 50, and the film coating mechanism includes a Coating roll 20 distributed on the membrane, motor 21 for driving the coating roll 20 to rotate, and a coating guide roll for making the diaphragm contact with the coating roll 20, said coating guide roll includes a first coating layer set at a distance. Guide roller 22 and the second coating guide roller 23, described first coating guide roller 22 and the second coating guide roller 23 are positioned at the same side of coating roller 20, between described coating guide roller and coating roller 20 form a septum channel. Described thickness detection mechanism comprises stand 30, detection guide roller and infrared detector 33, and described detection guide roller comprises the first detection guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com