A platinum resistance temperature sensor for a hydraulic system and its application method

A technology of temperature sensor and hydraulic system, which is applied to thermometers, thermometers, and electrical devices that use electrical/magnetic components directly sensitive to heat. It can solve the problems of low temperature measurement accuracy, and achieve flexible layout and high measurement accuracy. , the use of good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

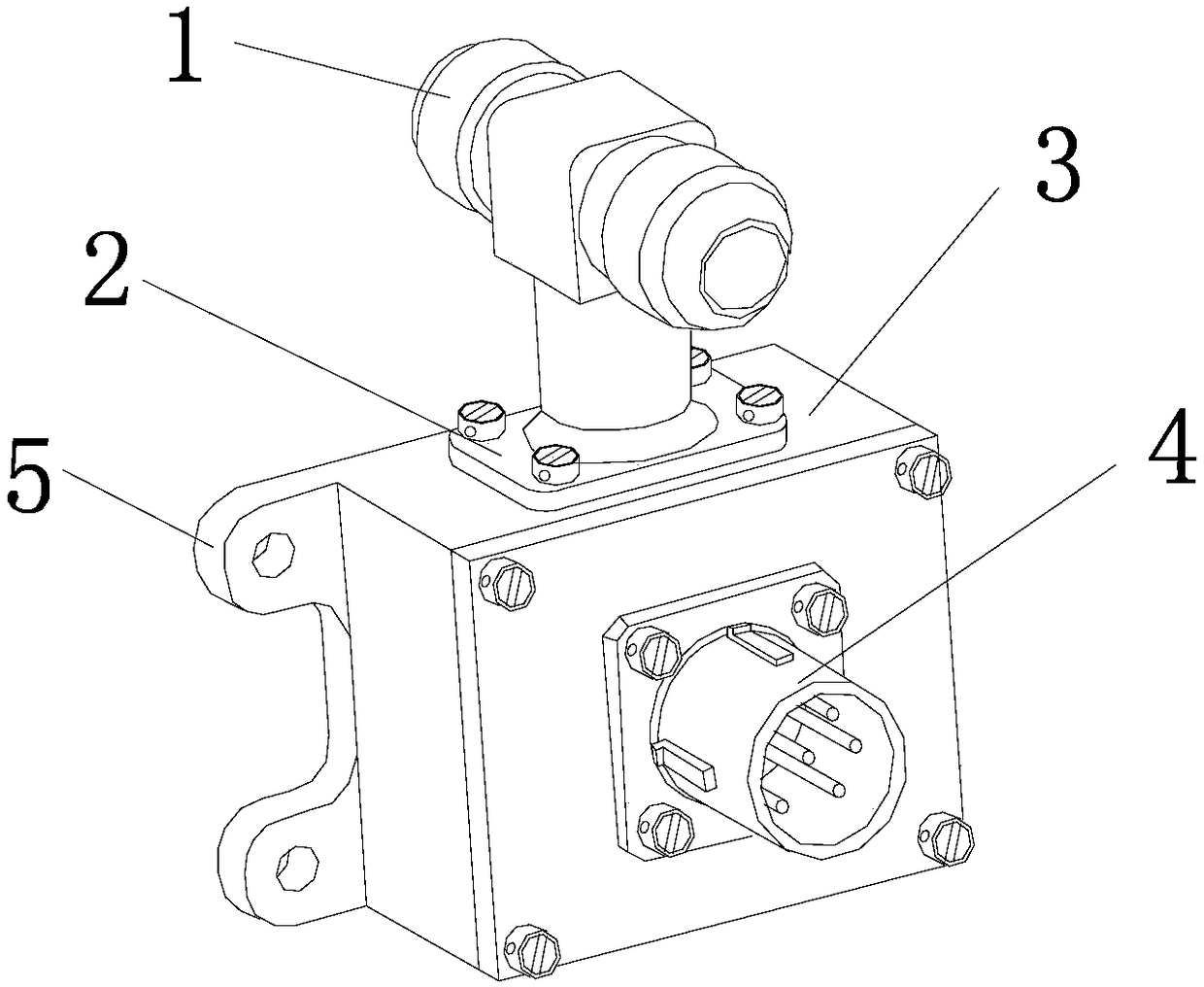

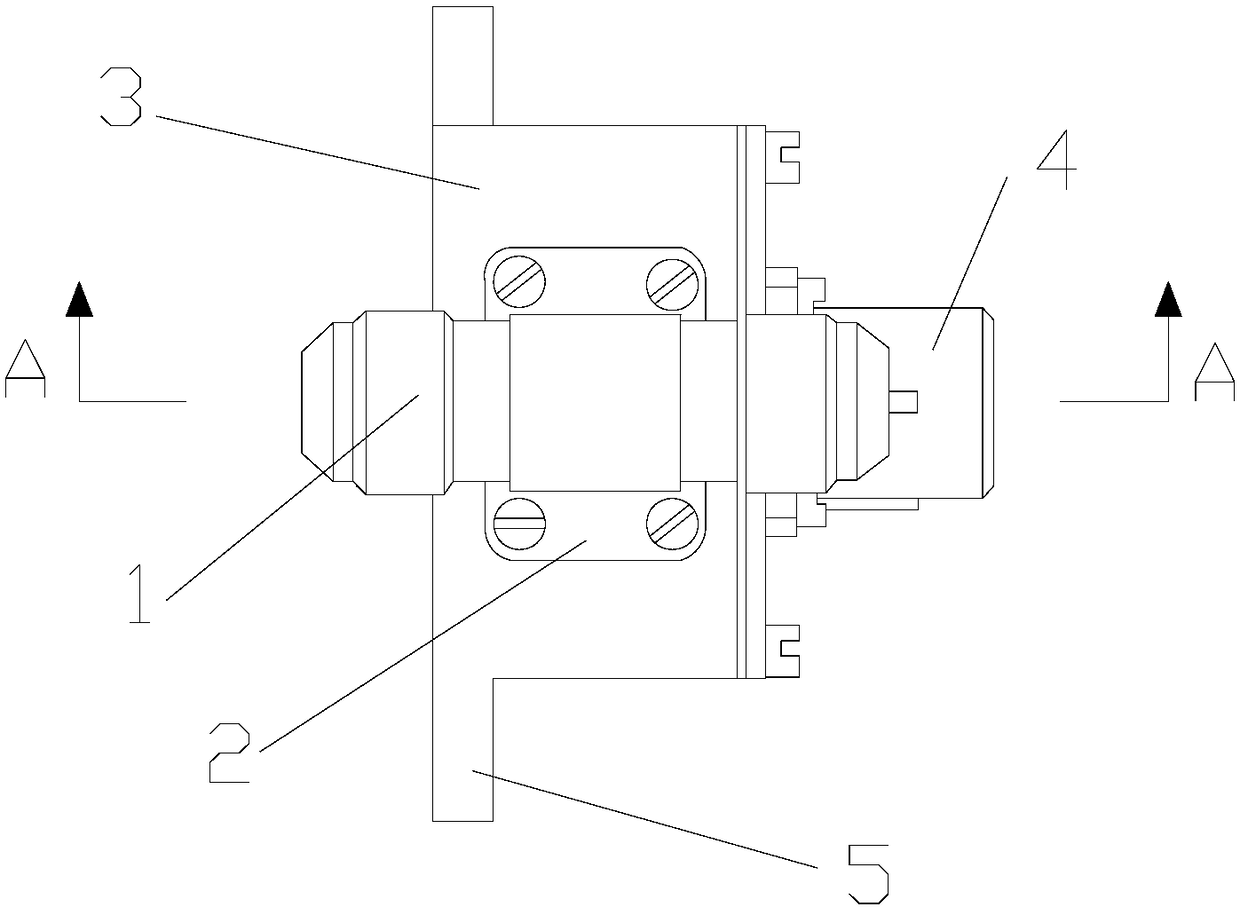

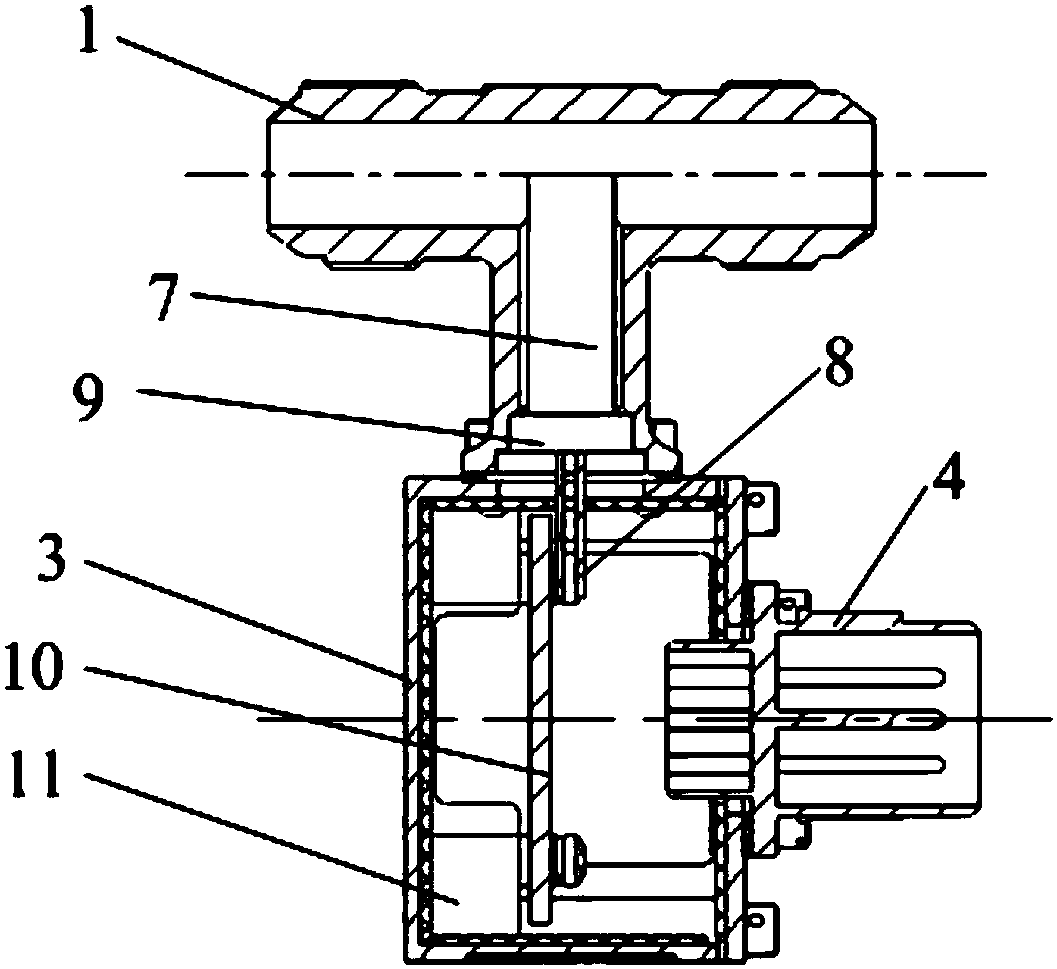

[0037] Such as figure 1 , figure 2 and image 3As shown, a platinum resistance temperature sensor for a hydraulic system according to the present invention includes a three-way measuring front end installed on the hydraulic pipeline and a signal conversion box installed on the hydraulic system support and connected to the three-way measuring front end 3. The three-way measuring front end includes a three-way pipe 1 connected to the hydraulic pipeline at both ends and a temperature-sensing component arranged in the third pipeline of the three-way pipe 1, and the third pipeline of the three-way pipe 1 is installed outside There is a flange mounting part 2, the temperature sensing part includes a cylindrical support 6 and a platinum resistance 7 installed on the cylindrical support 6 and extending into the center line of the hydraulic pipeline, the cylindrical support 6 is threaded with the flange mounting part 2 Connection; the signal conversion box 3 includes a housing, a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com