Rotary permanent-magnet suction scheme capable of switching on/off shielding in groove

An internal rotation, magnetic technology, applied in the direction of electrical components, generators/motors, etc., can solve the problems of incomplete demagnetization, large demagnetization conversion resistance and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

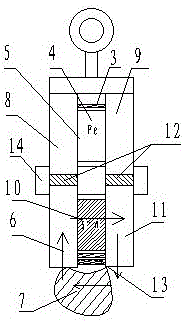

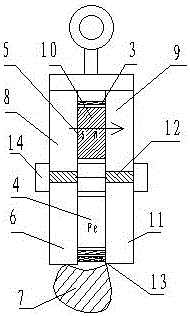

[0018] Embodiment 1: as figure 1 , 2 As shown, the lower working pole 6 and the upper working pole 8 are separated by a magnetic separator 12, and the upper working magnetic pole 9 and the lower working magnetic pole 11 are also separated by a magnetic separator 12, and a cylinder 3 is arranged in the middle of them, and the cylinder 3 An iron body 4 and a permanent magnet 10 are arranged, and a shaft 14 is connected among them, and a protective plate 13 is arranged on the lower part thereof. Wherein the rotatable body 1 that cylinder body 3, iron body 4 and permanent magnet 10 are formed can rotate with shaft 14, when rotating to figure 1 When it is in the magnetic state, when it is rotated to figure 2 It is in the degaussed state.

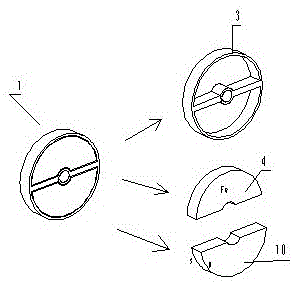

[0019] another example image 3 Shown is an exploded view of the rotatable body 1 . Wherein the cylindrical body 3 has an inner shaft sleeve and reinforcing ribs.

Embodiment 2

[0020] Embodiment 2: as Figure 4 As shown, stacking several examples 1 can also become a magnetic pick-and-release solution.

Embodiment 3

[0021] Embodiment 3: as Figure 5 As shown, in Example 1, several rotating bodies and shafts are stacked in the direction shown, which can become another magnetic suction and release scheme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com