Induction cooker

A technology of an induction cooker and a power-on end is applied in the field of induction cookers, which can solve the problems of poor heat dissipation of light-emitting components and affect the service life of the induction cooker, and achieve the effects of facilitating heat dissipation, reducing heat, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

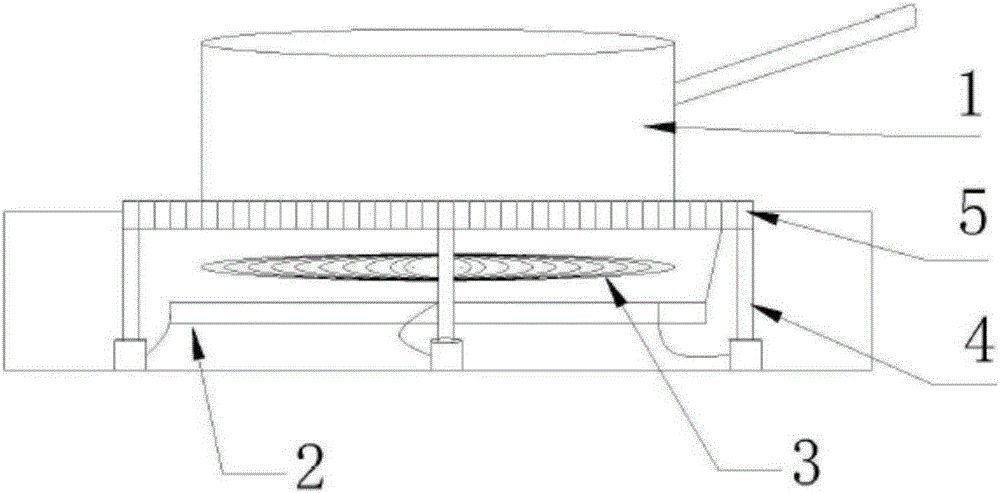

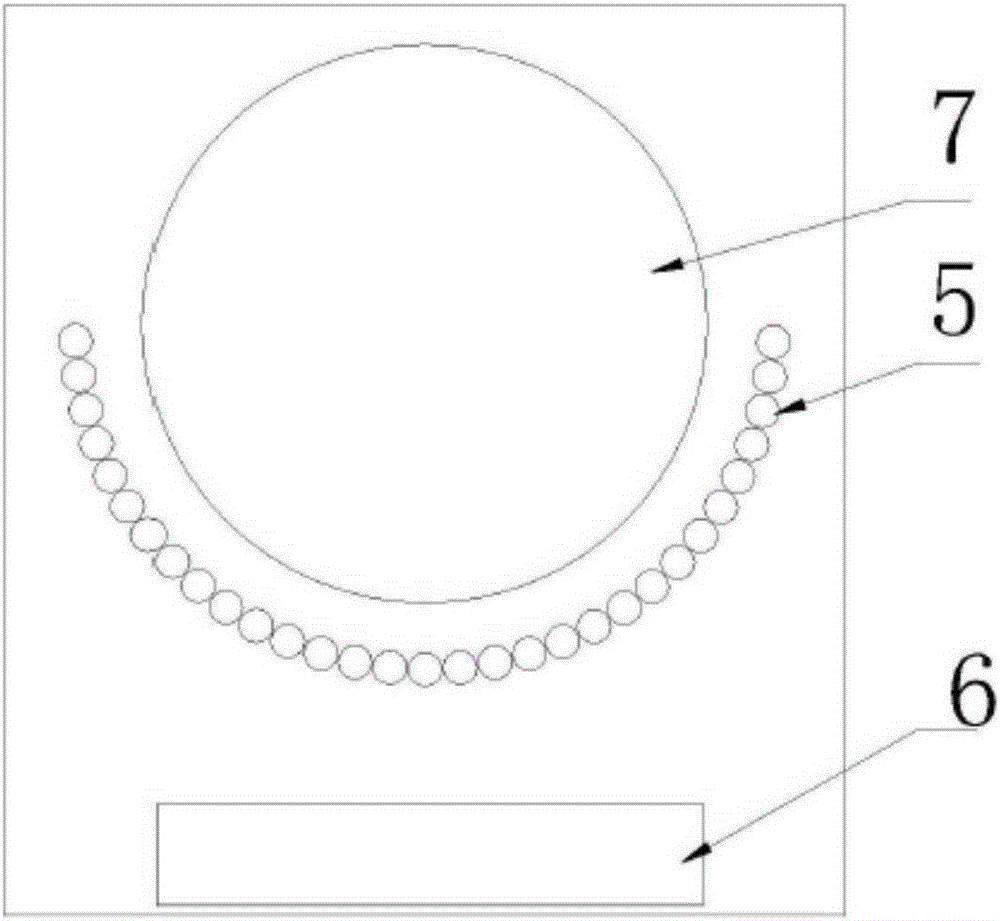

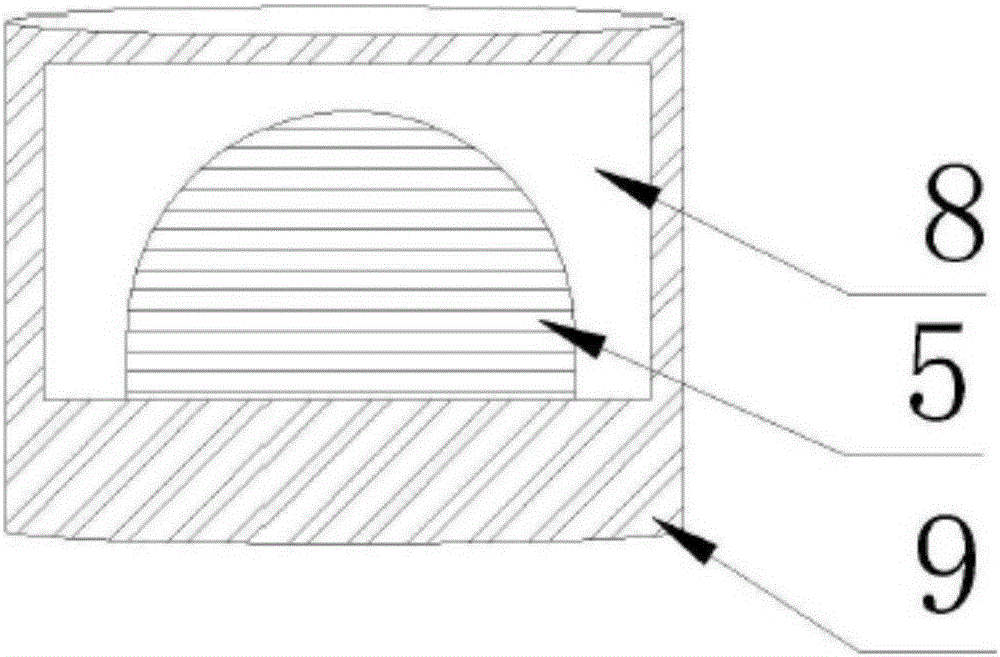

[0039] Figure 4 It is a schematic diagram of the explosion structure of the electromagnetic oven of the present invention, Figure 5 It is a schematic diagram of the installation of the luminous body provided by the present invention, Figure 6 It is a schematic diagram of the explosive structure of the firepower visual box in the electromagnetic oven of the present invention, Figure 7 Schematic diagram of the structure of the fire visual box provided by the present invention. Such as Figure 4 to Figure 7 As shown, the induction cooker provided in this embodiment includes a bottom case 10 and a panel 20 covered on the bottom case 10, the panel 20 includes a fire power viewing area 21, and the bottom case 10 is provided with a light-emitting assembly 30. The light-emitting assembly 30 includes multiple Each illuminant 31, each illuminant 31 includes a light-emitting end 311 and a power-on end 312, at least part of the light emitted by the light-emitting end 311 hits the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com