Cigarette with cut tobaccos being cut reconstituted tobaccos and cut tobacco stems

A technology for shredded tobacco leaves and cigarettes, applied in the field of tobacco products, can solve the problems of irritation and miscellaneous gas, low utilization rate of cigarette formulations, etc., and achieve the effects of less irritation, mellow taste and less miscellaneous gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

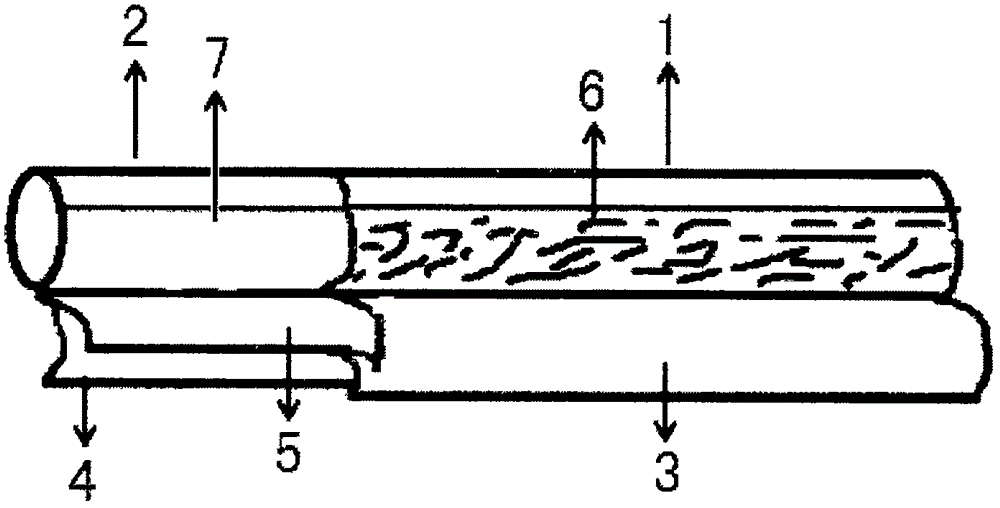

Image

Examples

Embodiment 1

[0020] The reconstituted tobacco leaves are prepared according to the traditional paper-making process of the tobacco industry. The shredded tobacco stems are cut into 1.0mm in width and processed in a separate process. The processing mode is low-intensity processing. The moisture content after feeding is 14%. Cigarette stem cutting process route processing. The prepared shredded reconstituted tobacco leaves and cut stems are blended in a fixed ratio, and the blending ratio of shredded reconstituted tobacco leaves and cut stems is 1:1.

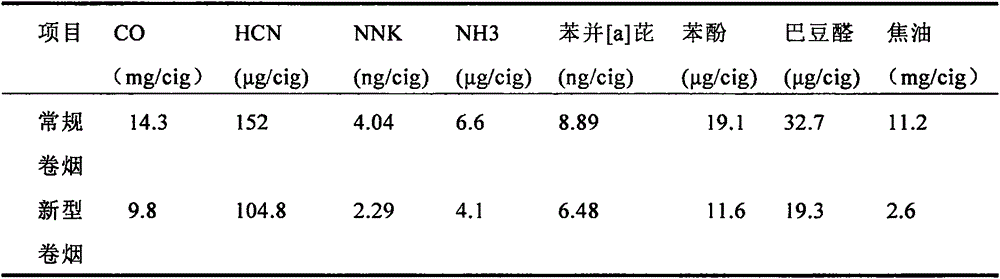

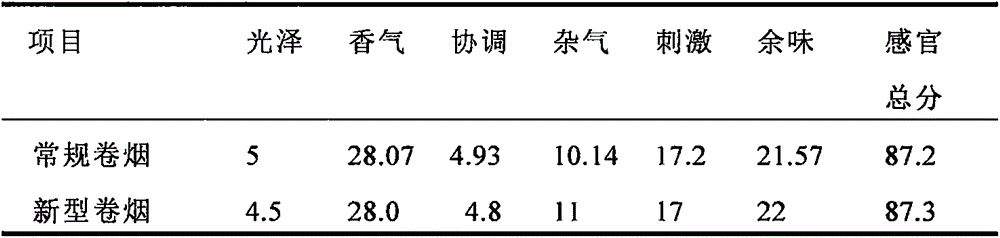

[0021] The test results are shown in Table 1 and Table 2. The results show that compared with normal cigarettes, reconstituted shredded tobacco leaves and cut stems have much lower harmful components in smoke, and the content of harmful components in new cigarettes can also be greatly reduced compared with conventional cigarettes. The sensory quality of the new cigarettes is mellow in taste, less irritating and less miscellaneous.

[0022] Ta...

Embodiment 2

[0027] The reconstituted tobacco leaves are prepared according to the traditional paper-making process of the tobacco industry. The shredded tobacco stems are cut into 1.0mm in width and processed in a separate process. The processing mode is low-intensity processing. The moisture content after feeding is 14%. Cigarette stem cutting process route processing. The finished shredded reconstituted tobacco leaves and cut stems are blended in a fixed ratio, and the blending ratio of shredded reconstituted tobacco leaves and cut stems is 7:3. Flavoring treatment is carried out after blending.

[0028] The test results are shown in Table 3 and Table 4. The results show that compared with normal cigarettes, the harmful components in the smoke of reconstituted shredded tobacco leaves and cut stems are much reduced, and the content of harmful components in new cigarettes can also be greatly reduced compared with conventional cigarettes. The sensory quality of the new cigarettes is mello...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com