Cigarette with recreated cut tobacco leaves and cut stems as cut tobacco and filter tip containing nano granular material

A technology of nano-particles and reconstituted tobacco leaves, which is applied in the fields of e-liquid filter elements, tobacco, and tobacco preparation. It can solve the problems of stimulation and miscellaneous gas, and the low utilization rate of cigarette formula, so as to achieve small irritation, mellow taste, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

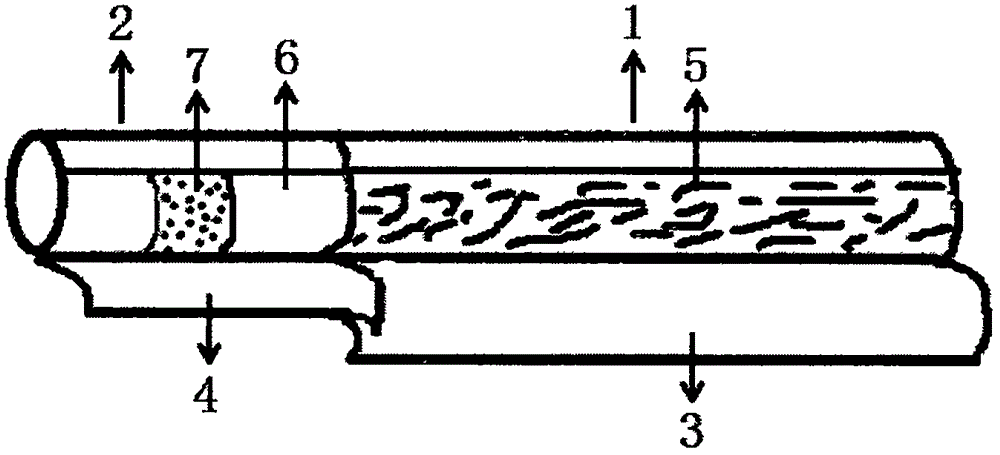

[0027] figure 1 Be the structural representation of embodiment 1, the manufacturing process of cigarette is:

[0028] The shredded reconstituted tobacco is prepared according to the traditional papermaking process of the tobacco industry. The shredded reconstituted tobacco leaf in the cigarette is made as follows: the shredded width is 1.0 mm, processed according to the cigarette shredded process route, and the mass percentage of moisture after feeding is between 12% and 16%. ; The cutting width of tobacco stems is 1.2mm, and it is processed according to the technological route of making cut tobacco stems. The prepared shredded reconstituted tobacco leaves and cut stems are blended in a fixed ratio, and the blending mass ratio of shredded reconstituted tobacco leaves and cut stems is 1:1. Flavoring treatment is carried out after blending. The filter tip 2 is a binary composite filter element composed of cellulose acetate tow 6 and nanoparticles 7, which is filled with hydrop...

Embodiment 2

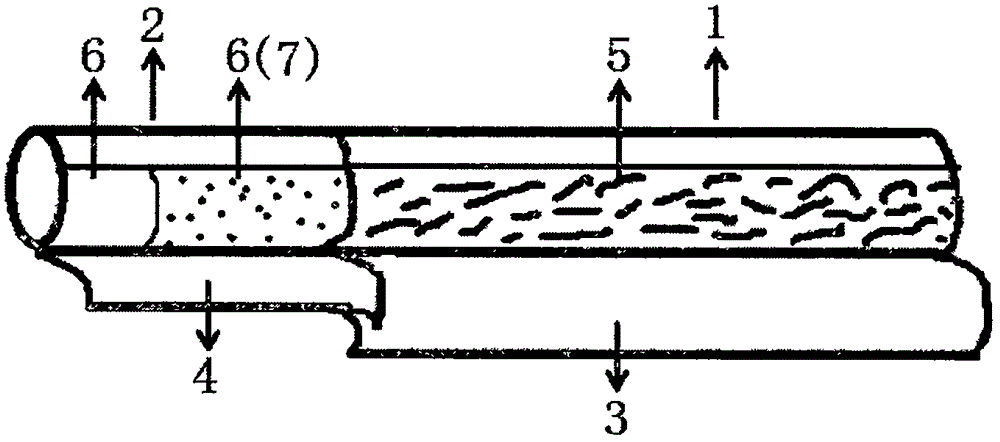

[0035] figure 2 It is the structural representation of embodiment 2,

[0036] The shredded reconstituted tobacco is prepared according to the traditional papermaking process of the tobacco industry. The shredded reconstituted tobacco leaf in the cigarette is made as follows: the shredded width is 1.0 mm, processed according to the cigarette shredded process route, and the mass percentage of moisture after feeding is between 12% and 16%. ; The cutting width of tobacco stems is 1.2mm, and it is processed according to the technological route of making cut tobacco stems. The prepared shredded reconstituted tobacco leaves and cut stems are blended in a fixed ratio, and the blending mass ratio of shredded reconstituted tobacco leaves and cut stems is 7:3. Flavoring treatment is carried out after blending. The filter tip 2 is a binary composite filter element composed of cellulose acetate tow 6 and nanoparticles 7, which is composed of acetate cellulose tow sections and nanopartic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com