Rubber vulcanization process

A rubber vulcanization and process technology, applied in the field of rubber vulcanization, can solve the problems of bulging, edge burning, defective product rate, increase in reject rate, etc., and achieve the effect of improving stability, reducing defective products and maintaining quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

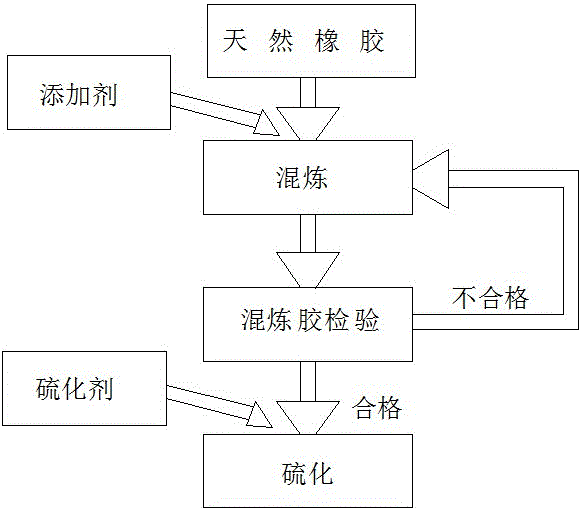

[0040] The rubber vulcanization process of the present invention comprises the following steps of mixing, rubber compound inspection and vulcanization:

[0041] 1) Mixing:

[0042] Styrene butadiene rubber, butadiene rubber, zinc oxide, stearic acid, anti-aging agent 4010NA, anti-aging agent RD, anti-aging agent D, accelerator M, accelerator DM, paraffin, coumarone, carbon black N330, carbon black N660, Engine oil, according to the mass percentage, is 70:30:4.6:1.8:0.9:0.9:0.8:0.7:1.2:0.5:5:38:20:15. After mixing, add it to the internal mixer for mixing, and control the density The mixing temperature of the mill is 40°C, and the mixing time is 20 minutes;

[0043] 2) Compound rubber inspection:

[0044] Sampling and testing the mixed rubber after mixing, the method and test value shall be carried out according to the following method and value, and the mixed rubber with all the test values qualified shall be selected:

Embodiment 2

[0057] The rubber vulcanization process of the present invention comprises the following steps of mixing, rubber compound inspection and vulcanization:

[0058] 1) Mixing:

[0059]Styrene butadiene rubber, butadiene rubber, zinc oxide, stearic acid, anti-aging agent 4010NA, anti-aging agent RD, anti-aging agent D, accelerator M, accelerator DM, paraffin, coumarone, carbon black N330, carbon black N660, Engine oil, according to the mass percentage, is 70:30:4.6:1.8:0.9:0.9:0.8:0.7:1.2:0.5:5:38:20:15. After mixing, add it to the internal mixer for mixing, and control the density The mixing temperature of the mill is 80°C, and the mixing time is 10 minutes;

[0060] 2) Compound rubber inspection:

[0061] Carry out sampling test on the mixed rubber after mixing, the method and test value shall be carried out according to the following method process and value, and the mixed rubber with all test values qualified shall be selected:

Embodiment 3

[0074] The rubber vulcanization process of the present invention comprises the following steps of mixing, rubber compound inspection and vulcanization:

[0075] 1) Mixing:

[0076] Styrene butadiene rubber, butadiene rubber, zinc oxide, stearic acid, anti-aging agent 4010NA, anti-aging agent RD, anti-aging agent D, accelerator M, accelerator DM, paraffin, coumarone, carbon black N330, carbon black N660, Engine oil, according to the mass percentage, is 70:30:4.6:1.8:0.9:0.9:0.8:0.7:1.2:0.5:5:38:20:15. After mixing, add it to the internal mixer for mixing, and control the density The mixing temperature of the mill is 60°C, and the mixing time is 15 minutes;

[0077] 2) Compound rubber inspection:

[0078] Carry out sampling test on the mixed rubber after mixing, the method and test value shall be carried out according to the following method process and value, and the mixed rubber with all test values qualified shall be selected:

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| hardness change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com