Liquid crystal polyester molding composition and application thereof

A technology of molding composition and liquid crystal polyester, which is applied in the direction of liquid crystal materials, chemical instruments and methods, etc., and can solve problems such as the impact on the use stability of precision exhaust blade parts, affecting the exhaust effect and use stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-21 and comparative example 1-2

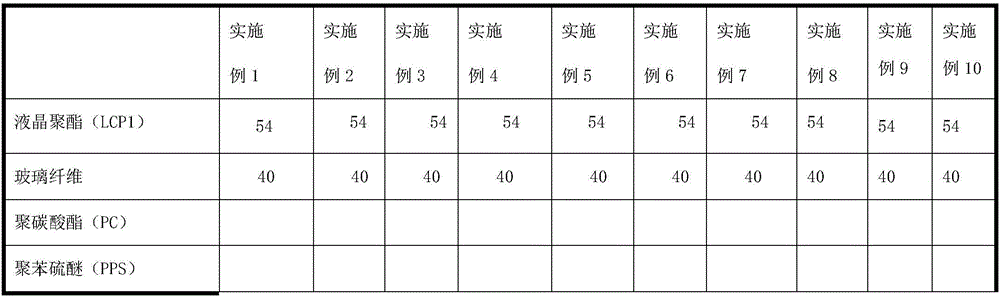

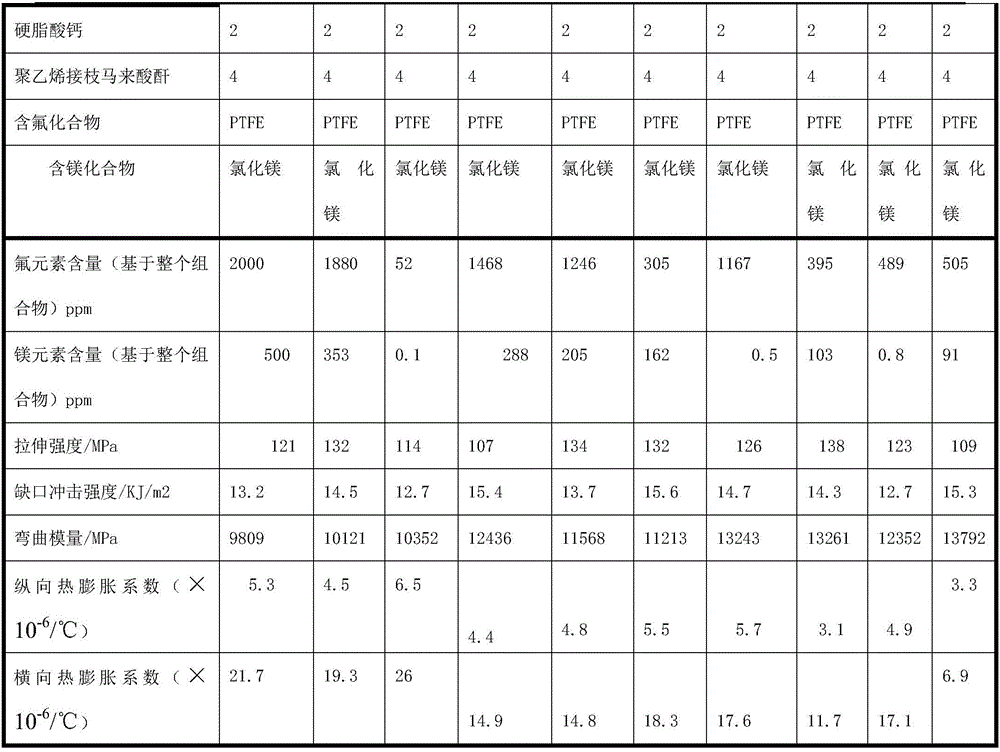

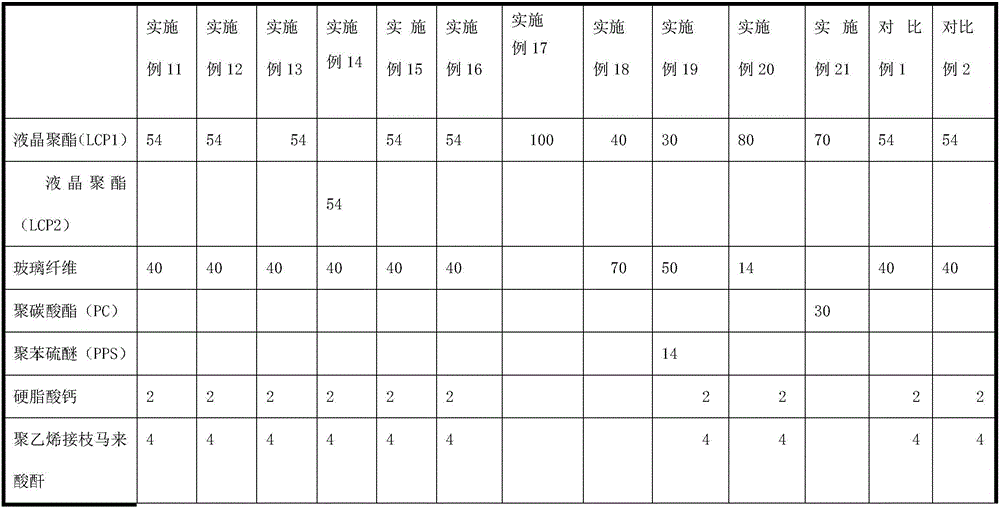

[0068] Example 1-21 and Comparative Example 1-2: Preparation of Liquid Crystal Polyester Molding Composition

[0069] (1) Dry the liquid crystal polyester and other thermoplastic resins at a temperature of 100-150° C. for 4-6 hours;

[0070] (2) Use a high-speed mixer to mix other additives that need to be added evenly, and dry at 80°C for 4-6 hours;

[0071] (3) Mix the dried materials (1) and (2) with fluorine-containing compounds or fluorine-containing polymers and magnesium-containing compounds according to the ratio shown in Table 1, and then put them into the main body of the twin-screw extruder. Feed port, add reinforcing filler from the side feed port of the extruder, melt extrude and granulate. Performance tests were performed on the liquid crystal polyester molding composition, and the data are shown in Table 1.

[0072] Among them, the weight content of fluorine element and magnesium element in the liquid crystal polyester molding composition is determined by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com