40 micron ultra-thin metal bond diamond dicing knife for Faraday rotator and its application

A Faraday rotator and ultra-thin metal technology, which is applied to other manufacturing equipment/tools, engine components, mechanical equipment, etc., can solve problems such as frequent tool changes, unusable blades, poor self-sharpening of scribing knives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

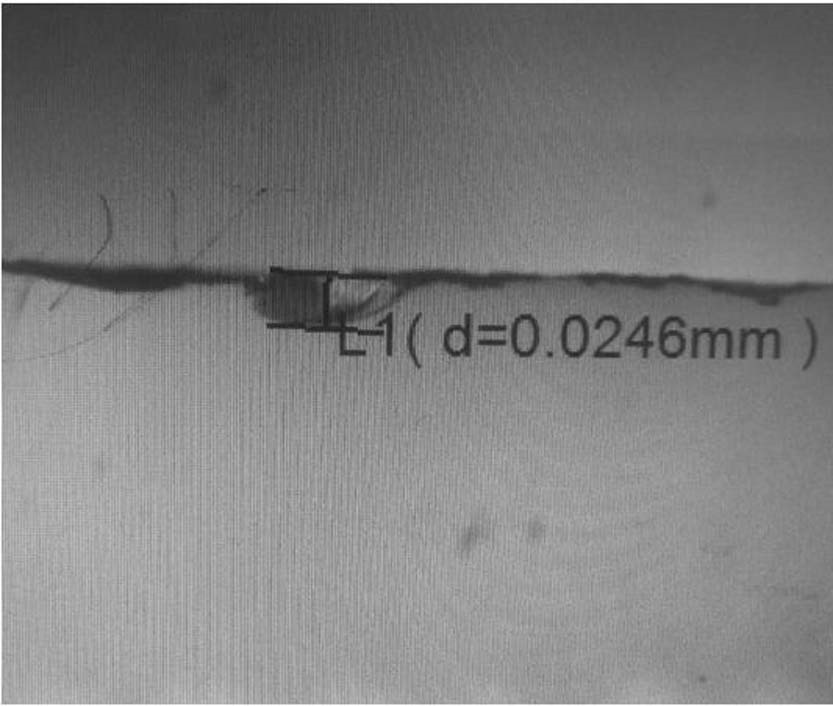

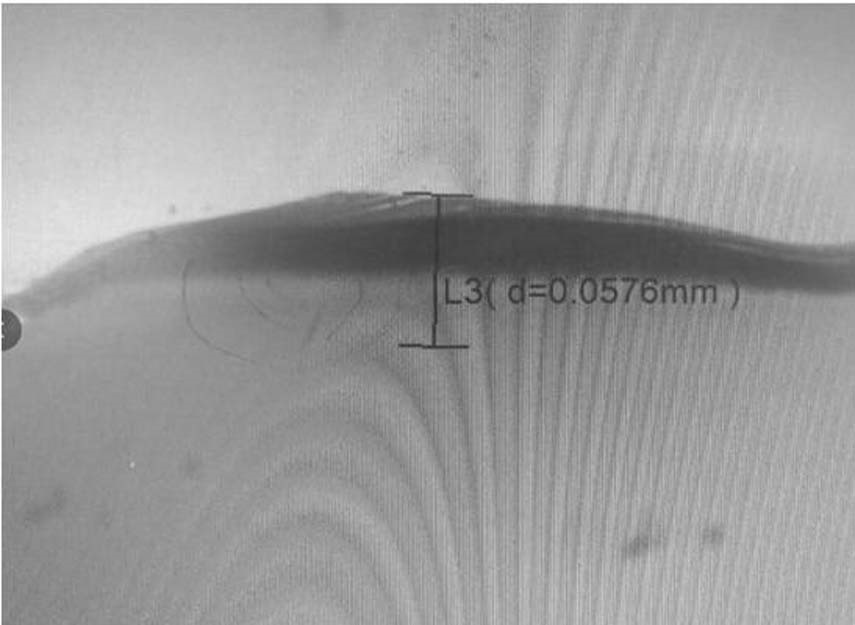

Image

Examples

Embodiment 1

[0038] A metal bond, consisting of the following raw materials in parts by weight: 65% copper powder, 25% tin powder, 6% aluminum oxide, 0.5% titanium hydride, and 3.5% graphite balls; the particle size of the copper powder is 10 μm , The particle size of tin powder is 10 μm, that of aluminum oxide is 2 μm, that of titanium hydride is 2 μm, and that of graphite balls is 2 μm.

[0039] Faraday rotator uses 40 micron ultra-thin metal bond diamond dicing knife, and its preparation method comprises the following steps:

[0040] (1) Material mixing: Put accurately weighed copper powder, tin powder, aluminum oxide, and titanium hydride into the three-dimensional mixer in sequence, then add liquid paraffin and pre-mix for 2 hours, then add graphite balls, mix for 3 hours, and finally Add diamond and mix for 1 hour, pass through a 120 mesh screen, and sieve 3 times to ensure that the material does not agglomerate and obtain a uniformly mixed material; the amount of liquid paraffin add...

Embodiment 2

[0047] A metal bond, consisting of the following raw materials in parts by weight: copper powder 68%, tin powder 23%, aluminum oxide 5%, titanium hydride 0.8%, graphite ball 3.2%; the particle size of the copper powder is 10 μm , The particle size of tin powder is 10 μm, that of aluminum oxide is 2 μm, that of titanium hydride is 2 μm, and that of graphite balls is 2 μm.

[0048] Faraday rotator uses 40 micron ultra-thin metal bond diamond dicing knife, and its preparation method comprises the following steps:

[0049] (1) Material mixing: Put accurately weighed copper powder, tin powder, aluminum oxide, and titanium hydride into the three-dimensional mixer in sequence, then add liquid paraffin and pre-mix for 2 hours, then add graphite balls, mix for 3 hours, and finally Add diamond and mix for 1 hour, pass through a 120 mesh screen, and sieve 3 times to ensure that the material does not agglomerate and obtain a uniformly mixed material; the amount of liquid paraffin added is...

Embodiment 3

[0056] A metal bond, consisting of the following raw materials in parts by weight: 70% copper powder, 21% tin powder, 4.5% aluminum oxide, 0.5% titanium hydride, and 4% graphite balls; the particle size of the copper powder is 15 μm , The particle size of tin powder is 10 μm, that of alumina is 4 μm, that of titanium hydride is 2 μm, and that of graphite balls is 3 μm.

[0057] Faraday rotator uses 40 micron ultra-thin metal bond diamond dicing knife, and its preparation method comprises the following steps:

[0058] (1) Material mixing: Put accurately weighed copper powder, tin powder, aluminum oxide, and titanium hydride into the three-dimensional mixer in sequence, then add liquid paraffin and pre-mix for 2 hours, then add graphite balls, mix for 3 hours, and finally Add diamond and mix for 1 hour, pass through a 120 mesh screen, and sieve 3 times to ensure that the material does not agglomerate and obtain a uniformly mixed material; the amount of liquid paraffin added is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com